CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

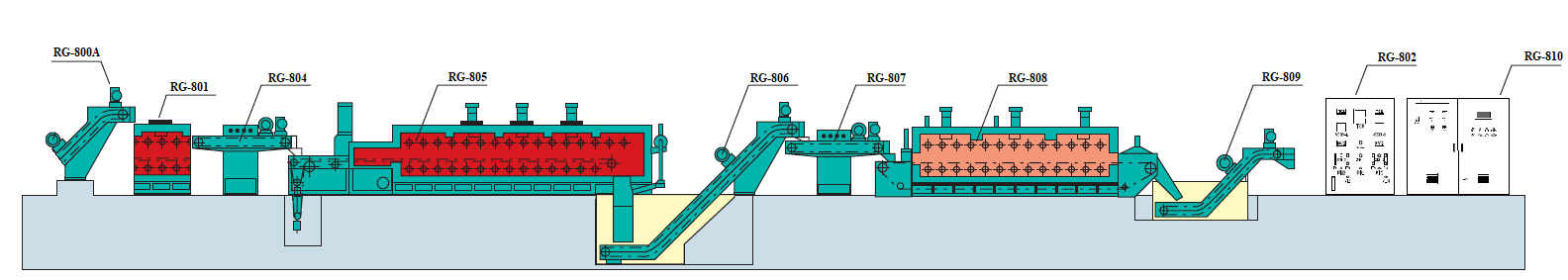

QUENCHING FURNACES WITH CONVEYOR BELTS FROM WIRE LINKS

GAS BURNER HEATING TYPE or ELECTRIC HEATING TYPE?

This is the Main Furnace of the Conveyor Quenching-Tempering Unit for Heat Treatment of Fasteners.

Quenching furnaces are electrically heated or gas heated.

RG-805G [Gas Burner Heating Type] Continuous Bright Carburizing (Hardening) Quenching Furnace

In this furnace the products go through hardening, carburizing or carburnitriding treatment with atmosphere after being washed in the front washing machine.

In this furnace the products go through hardening, carburizing or carburnitriding treatment with atmosphere after being washed in the front washing machine.

For carburizing or tempering screws, nuts, bicycle parts, car parts, forged parts, hand tools, hardware parts, etc.

Techical Specifications of Gas Burner Heating Type Continuous Quenching Furnace

| Model | Treating Capacity | Conveyer Width (mm) | Inside Height (mm) | Length of Heating Section (mm) | Combustion Ability (kcal/hr) | Power (Max) (kW) | |

|---|---|---|---|---|---|---|---|

| to Middle / High Carbon Steel (kg/hr) | to Low Carbon Steel (kg/hr) | ||||||

| RG-805G-4 | 506-572 | 413-463 | 800 | 100 | 6000 | 180000 | 45 |

| RG-805G-5 | 720-780 | 546-598 | 800 | 100 | 8000 | 300000 | 90 |

| RG-805G-6 | 1000-1100 | 833-917 | 800 | 100 | 10000 | 400000 | 90 |

| RG-805G-6S | 1200-1320 | 999-1100 | 800 | 100 | 12000 | 450000 | 95 |

| RG-805G-7 | 1250-1375 | 1040-1146 | 1000 | 100 | 10000 | 467000 | 95 |

| RG-805G-7S | 1500-1650 | 1249-1375 | 1000 | 100 | 12000 | 525000 | 135 |

| RG-805G-8 | 1800-1980 | 1499-1650 | 1200 | 100 | 12000 | 690000 | 135 |

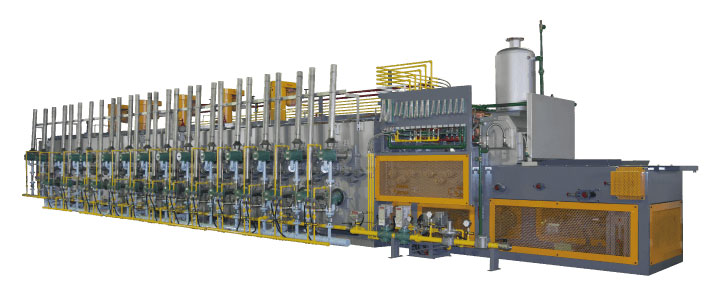

Outlook of installed Gas Burner Heating Type Continuous Hardening Furnace

The content of the equipment of the hardening furnace with conveyor belt of heat-resistant steel wire links

- Radiant heating system with heat recovery gas burners;

- Wire links Band;

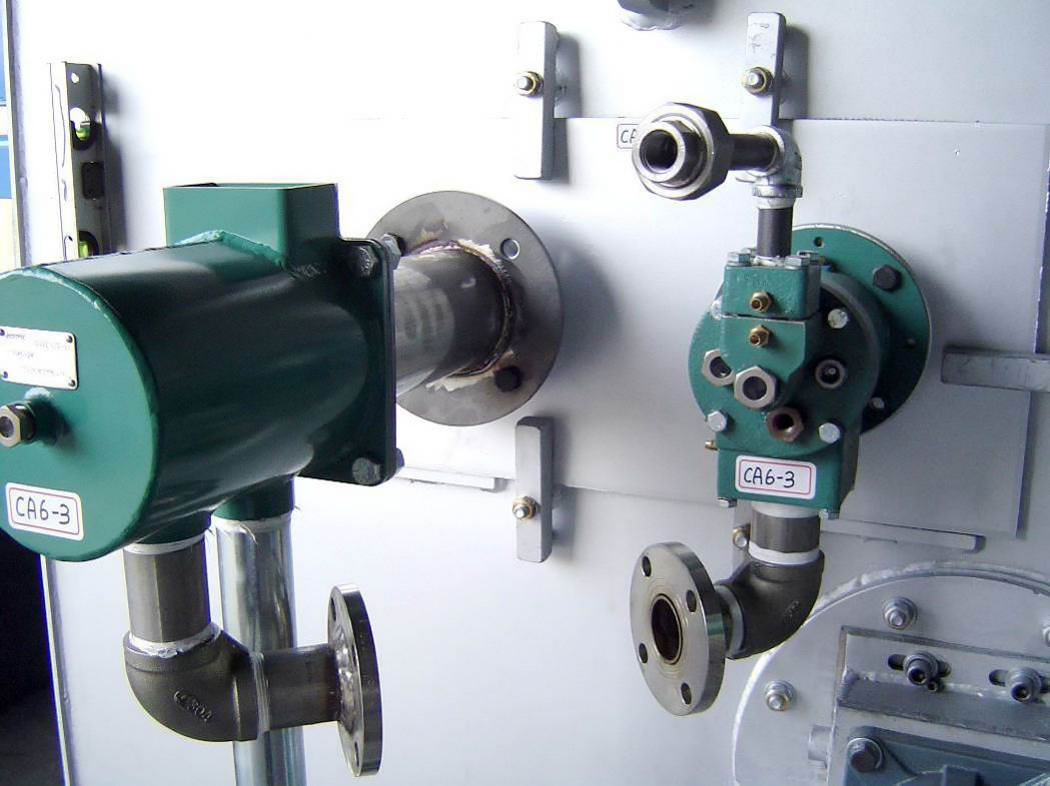

- Inlet gas regulator;

| Purging gas (emergency) | Nitrogen |

| Shielding gas | Endogas |

| Regulating gas | Propane + air |

| Consumption of propane (gas regulator) | 5 m3/h |

| Maximum temperature in the furnace | 930°C |

| Operating temperature range | 800…900°C |

| Useful width of the furnace | 800 mm |

| Useful length of the inner space of the furnace (preheating zone) | 10,5 m |

| Clear height of passage | 100 mm |

| Useful area of the conveyor furnace (* see Note) | 0,73 × 13 = 9,49 m2 |

| Outer length of the furnace | 14000 mm |

| Maximum power consumption for gas heating | 7,8 kW |

| The power consumed by motors | 7,68 kW |

| Shielding gas consumption | 40…45 m3/h |

| Natural gas consumption | 45 m3/h |

| Purging gas consumption(for one purge) | about 40…65 m3/h |

| Number of heating zones | 5 |

| The number of fans for heated gas mixing | 4 |

| The time of processing products in the furnace | 40…100 min |

Note: The calculation was based on the fact that the internal length of the furnace with the preheating zone and the conveyor at the entrance of the furnace is 13m, so the useful length of the conveyor belt is 13 m;

Typical Components of hardening furnace RG-805G (for reference)

- Conveyer width 800 mm x inlet height 100 mm x heating length 12,000 mm x inlet length 3500 mm

- Construction: Welded by 2”x4” iron & 6 mm x 9 mm x 12 mm x 15 mm x 18 mm iron plates in sealed & strong construction, easy to maintain and is delivered by container

- Inner insulating materials:

- Insulating bricks: Japan Isolite LBK-23 × 1 unit

- Insulating cement: Japan P-150 × 1 unit

- Insulating plates: imported products × 1 unit

- Insulating paint: imported products × 1 unit

- Ceramic fiber: Japan 8P & 10P × 1 unit

- Heating constructionа:

- Type of burners: radiant tube type

- Model of burners: TFB 30 (ECLIPSE made in USA)

- Radiant tubes : HU casting pipe Ø114 mm × T:6 mm by U type (IMP made in Switzerland)

- Quantity of burners : 27 sets

- Temperature control system:

- Control system: PID control

- Control zones: 6 zones

- Thermocouple: K-type

- Conveyor belt:

- Belt type: Mesh type

- Material: SUS314S (made in Germany)

- Wires diameters: 2.0 mm × 3.0 mm

- Belt width: 800 mm

- Bending wall height: 20mm

- Total belt length: 31.5 meters

- Mixed fan:

- Fan materials: stainless SUS310 shaft with SCH22 blade

- Fan type: propeller type, design is patented (made in Taiwan)

- Speed: 900RPM

- Sensor: proximity switch

- Motor: 2 HP (1.5 kW)

- Total quantity: 5 sets

- Cooling type: air-cooling type, design is patented (made in Taiwan)

- Max operation temperature: 930°C

- Driving system:

- Motor: inverter motor 2.2 kW (3HP) + gear box 1/900

- Control: Inverter 2.2 kW (TE, made in France)

- Speed range: 40~200 minutes (from inlet to outlet)

- Driving type: roller type

- Driving rollers:

- Construction: up roller, under roller, main roller, design is patented (made in Taiwan)

- Materials: stainless with SCH22

- Bearing: Heating side by un-lubrication bearing (design is patented), driving side by UCFL 207 bearing (made in Japan)

- Cooling house of bearing: air-cooling type, aluminum casting construction (design is patented)

- Flow meters:

- Protective gas flow meters × 1 unit

- Enrich gas flow meters × 1 unit

- Ammonia flow meters × 1 unit

- Air flow meters × 1 unit

- Exhaust fan: 1/4 HP (0.25 kW) × 6P

- Outlet chute: SCH22 casting construction

- Pre-heating zone: Stainless fire curtains

- Water warmer: Uses heat from waste gases to heat water for washers

- Conveyor belt extending system × 1 unit

Note: the entire structure is made of stainless steel with insulation, and includes additional water pumps with switches that are located on the front and rear washers to circulate hot water.

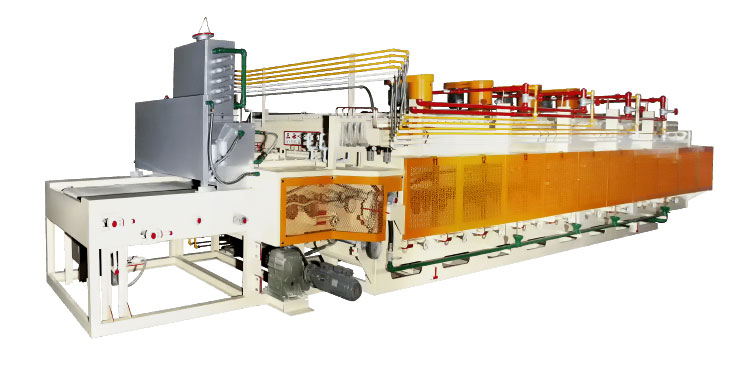

Continuous Bright Carburizing (Hardening) Quenching Furnace RG-805 [ELECTRIC HEATING TYPE]

Structural feature of the Electric Heating Type Quenching Furnace

- Electricity-saving: adopts high tensile calcium silicate board, ceramic fibre board, heat-resistant material for high performance.

- Operation: adopts automatic control to save manpower.

- Quality: adopts multi-stage control mixed fan in the furnace to get uniform temperature for high quality.

- Gas: adopts gas generator or methanol decomposition to stabilize gas and to ensure for quality.

- Stability: CP value tolerance ±0.03% (carbon potential), and the furnace temperature of uniformity at ±7.5°C.

- Adopts self-lubricant bearing (to save for maintenance with greasing).

- Maximum temperature in the furnace 930°C

Techical Specifications of Electrical Heating Type Continuous Quenching Furnace RG-805

| Model | Treating Capacity | Conveyer Width (mm) | Inside Height (mm) | Length of Heating Section (mm) | Inlet Lenght (mm) | Power (Max) (kw) | |

|---|---|---|---|---|---|---|---|

| to Middle / High Carbon Steel (kg/hr) | to Low Carbon Steel (kg/hr) | ||||||

| RG-805-A | 124-138 | 48-69 | 400 | 100 | 3000 | 3500 | 54-60 |

| RG-805-1 | 198-220 | 84-120 | 400 | 100 | 4000 | 3500 | 75-90 |

| RG-805-2 | 352-385 | 204-240 | 500 | 100 | 5500 | 3500 | 120-150 |

| RG-805-3 | 414-483 | 313-350 | 600 | 100 | 6000 | 3500 | 160-200 |

| RG-805-4 | 506-572 | 413-463 | 800 | 100 | 6000 | 3500 | 225-250 |

| RG-805-5 | 720-780 | 546-598 | 800 | 100 | 8000 | 3500 | 270-300 |

| RG-805-6 | 1000-1100 | 833-917 | 800 | 100 | 10000 | 3500 | 360-400 |

| RG-805-6S | 1200-1320 | 999-1100 | 800 | 100 | 12000 | 3500 | 400-450 |

| RG-805-7 | 1250-1375 | 1040-1146 | 1000 | 100 | 10000 | 3500 | 425-470 |

| RG-805-7S | 1500-1650 | 1249-1375 | 1000 | 100 | 12000 | 3500 | 480-530 |

Typical Components of Electrical Heating Type Hardening Furnace RG-805-2 (for reference)

- Construction: Welded by 2”x4” iron & 6 mm x 9 mm x 12 mm x 15 mm x 18 mm iron plates in sealed & strong construction, easy to maintain and is delivered by container.

- Inner insulating materials: energy-saving building blocks LBK-23 (Japan), heat-insulating energy-saving bricks SK36 (Japan), energy-saving plates, insulating wool for a temperature limit of 1600°C (Japan). SK36 can be melted into refractory clay, making it ideal for heat retention.

- Conveyor belt woven from wire made of stainless heat-resistant steel SUS310. The edges of the conveyor are folded up to prevent rolling products.

- Heating construction: 36 pcs of heating elements made from imported nickel-chrome wire, protected by a radiant heating seamless tube made of steel S310S (made in Japan), with an aluminum-porcelain insulator (made in Japan)

- The system of mixing the atmosphere in the heating chamber:

- Atmospheric mixing fan (heat-resistant steel SUS310): 2 sets

- Fan motor 1HP

- Bearings and cooling system: 2 sets

- Exhaust removal motor ¼HP: 1 set

- Drive system

- Inverter Motor 1HP

- Reducer 60 ~ 100: 1 set

- Drive chain with sprockets: 1 set

- Top rollers: 1 block

- Bottom rollers: 1 block

- Bearings: 1 block

- Main roller: 1 set

- Heating system: 1 setNote: water heating system for washing machines is installed at the beginning of the quenching furnace and uses the generated heat of the furnace.