HOT FORGING EQUIPMENT FOR FASTENERS, PARTS AND HARDWARE

DIE FORGING PRESS WITH LINK DRIVE RLP SERIES

Die forging press with link drive is characterized by die mold with particular angle of flexure that extends the life of equipment and reduce metal loss. This device supports large range of available operations as compared to the cranked press that makes high-quality mass production possible. The device is suitable for peripheral automatic feed equipment, moreover, it is widely used for cutting, flexing, presswork, as well as during deep drawing and calking.

Equipment peculiarities

- High accuracy, efficiency and quality of processed parts of products.

- Automatic production.

- Low noise and vibration.

- High speed and accuracy of products.

- Automatic lubricating fluid feed system.

- The accuracy of the equipment is confirmed by CNS standard.

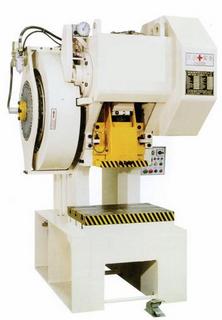

DIE FORGING PRESS WITH CROSS-SHAFT RH SERIES

Pneumatic die forging press with a cross-shaft is widely used for hot forging products of copper, aluminum and small parts of equipment.

Equipment peculiarities

- Strong hull of the equipment.

- The cross-shaft is made of strong and reliable alloy.

- Safety system.

- Automatic lubricating fluid feed system.

- The accuracy of the equipment is confirmed by CNS standard.

PNEUMATIC PRESS RC SERIES

The pneumatic press is used for cutting, flexing and forging of fine details. Ideal for cutting parts after stamping process.

Equipment peculiarities

- Special design of pneumatic braking and clamp provides a strong stamping process.

- Strong hull of the equipment.

- Programmable command device provides security of work process.

- Low noise and vibration.

- Automatic lubricating fluid feed system.

- The accuracy of the equipment is confirmed by CNS standard.