WIRE PROCESSING EQUIPMENT

WIRE PROCESSING EQUIPMENT

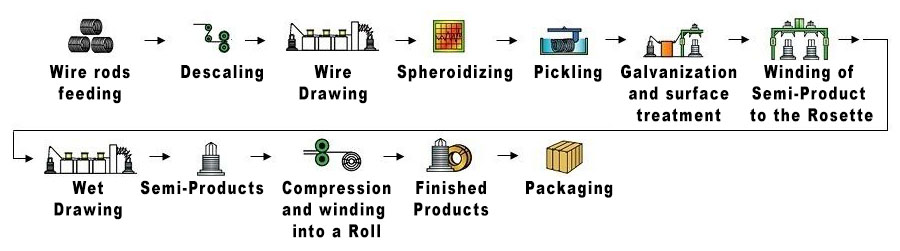

Technological process of manufacturing wire includes a number of classical operations that are repeated from 1 to 3 times depending on the diameter of the wire ordered:

- Wire cleaning

- Mechanical descaling

- Wire drawing on a predetermined diameter

- Wire pointing

- Wire annealing

- Wire pickling

- Wire galvanizing. (wire zinc plating, wire copper plating, wire nickel plating, wire tin plating, wire silvering, hot-dip zinc-aluminum wire coating)

- Winding the wire to the rosette, wire packaging

- Finished products

To provide special properties of the wire in the wire manufacturing there are additional input operations, such as, for example, application of various coatings or heat treatment. Heat treatment of wire is performed in furnaces with light acid heating. For descaling the solutions of sulfuric and hydrochloric acids are used. As pre-lubricating layer borax, phosphate salts, lime, copper are applied.

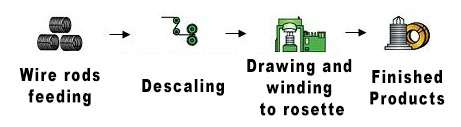

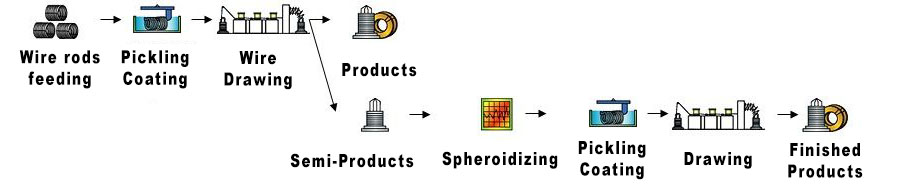

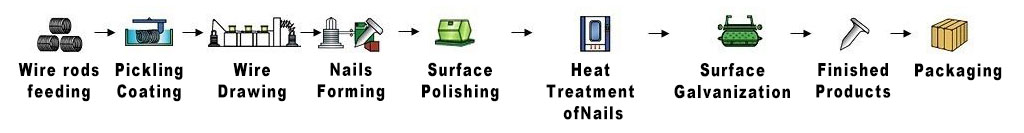

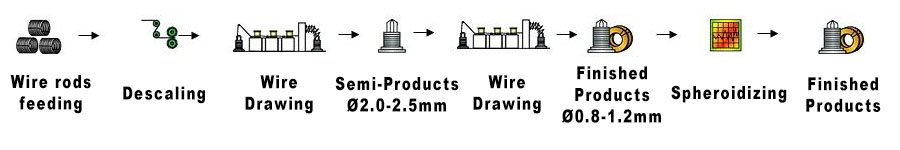

Technological process of manufacturing the wire, the order of classical operations depends on the type of manufactured products and its practical application (See below.)

FLOWCHART PROCESSES FOR MANUFACTURING WIRE OF DIFFERENT TYPE

The technological process of manufacturing wire, the order of classical operations depends on the type of manufactured products and its practical application:

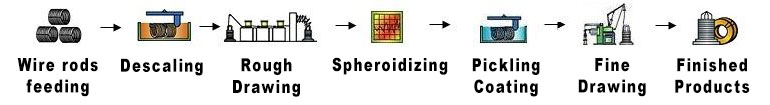

Production of wire from low carbon steel grade AISI 1008, 1018-1022 for the manufacture of screws, tapping screws and self-tapping screws

Production of wire from steel AISI 1010, 1020 for the manufacture of screw products, bolts, general purpose nuts

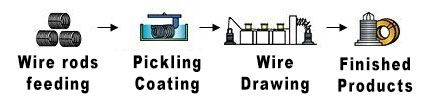

Production of wire from stainless steel 304, 316

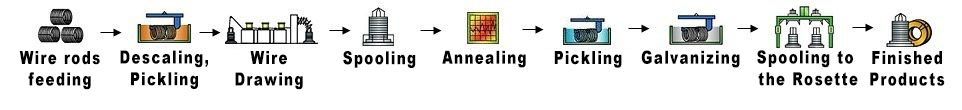

Production of galvanized wire

Wire production for a steel mesh fabrication

Production of wire from high carbon steel

Production of wire from high carbon steel for nails fabrication

Production of wire from low carbon steel for nails fabrication

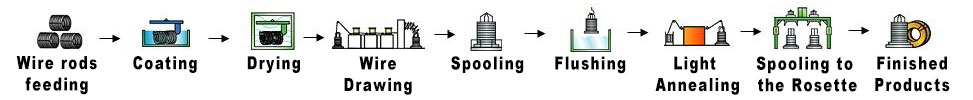

Production of Annealed Wire Ø0.8 mm – Ø1.2 mm

Production of general purpose wire with electroplated coating

Production of wire from carbon steel for making staples for the stapler

Wire drawing is made on camps with intensive cooling of dies and drums, which provides high strength and plastic properties of the metal. The use of modern lubricants provides the specific properties of the wire in accordance with customer requirements: a high corrosion resistance, a low amount of lubricant on the surface, high adhesion to various materials, and so forth. To improve the quality of produced wire drawing equipment is regularly updated and is equipped with additional devices for stress relief.

Galvanizing by dipping the wire in the melt allows to obtain different coating thicknesses. The use of special cleaning materials and emulsions makes zinc coating smooth, shiny, protected against corrosion for a long period of time.

Depending on the application and manufacturing technology to the consumer wire is supplied with different variants of the winding: in coils weighing from 5 to 180 kg, coils weighing from 200 to 1,000 kg, in coils like "Rosetta" in the coils BS type 60, welded wire frame.

Video presentation of the production of calibrated wire and turnkey hardware production

QUALITY ASSURANCE SYSTEM

Mandatory part of the process of manufacturing products is the technical control. The main functions of the technical control:

- Incoming control of raw materials.

- Control of the process of manufacturing products.

- Quality control of finished products.

When incoming inspection of raw materials is being verified by a certificate of quality of the incoming material and matching the actual properties of the products with the requirements of the contract for the supply.

Control of the process of manufacturing products applies to all operations, from the start in the production of wire rod. The control process is carried out according to the developed model, and specifically stipulates the place settings, frequency, measuring instruments, and the person in charge.

Quality control of finished products ensures that production requirements. Number of audited samples depends on the stability of the process, and the yield rate is specified in the technological instructions. According to the results of product testing issued a document on the quality certificate. On request, together with a certificate may be issued copies of test reports.