Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

WIRE CLEANING EQUIPMENT

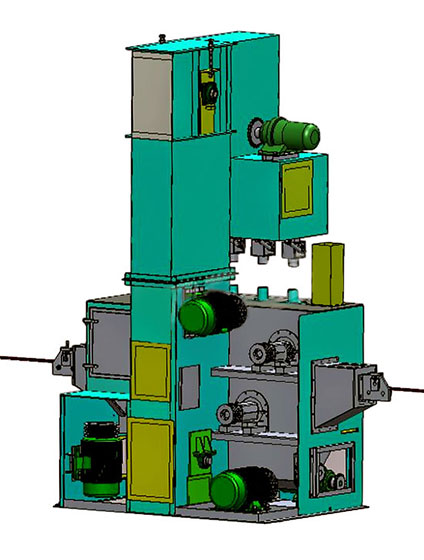

SHOT BLASTING EQUIPMENT FOR CONTINUOUS WIRE CLEANING

Shot blasting technology for metal

The technology of processing metal surfaces, which is based on the impact on the metal of small particles of a spherical type, is called shot blasting of metal. This method of working with metal products is a cold working method. Abrasives, which are supplied to a metal surface under high pressure in the course of blasting operations, have energy-kinetic properties. Due to this quality, carrying out shot-blasting operations makes it possible to completely remove greasy deposits from the surface and quickly achieve the required state of the material.

The use of shot blasting of metal makes it possible to effectively remove scale from the surface of the material, perform a global cleaning of rusty deposits, achieve the necessary roughness of the treated surface (for subsequent finishing operations), and, if necessary, make the surface matt. Also, shot-blasting work processes make it possible to completely remove corrosive foci from the metal surface. With the help of these works, an established relief contour of the product is formed and particles that have no connectivity are removed.

Application of shot blasting equipment

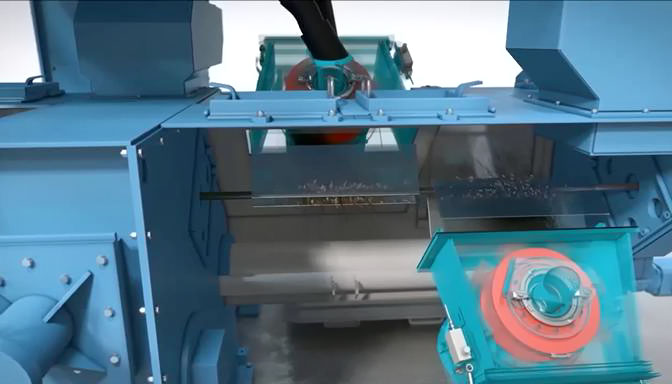

The shot blasting machine uses four high-speed shot-blasting turbines, powerful elastic streams of abrasive particles ejected by the turbine impellers hit the fast-moving surface of the wire. Shot streams remove the rust and oxide layer on the surface to produce a clean metal surface. The surface of the wire after such cleaning is free of rust and has a natural metallic color.

- Remove the corrosion and oxidation layer on the outer surface of wire.

- After shot blasting, the surface of wire presents uniform roughness.

- Eliminate the internal stress in the wire drawing process.

- It can increase the tensile strength and stress corrosion cracking resistance of the wire surface and obtain a long service life.

Equipment main technical parameters

| Cleaning workpiece range | |

|---|---|

| Processed material | High speed tool steel |

| Wire diameter | Ø6.0-32.0 mm |

| Feed speed | ≥50m/min (decided by the drawing machine or the retracting machine) |

| Impeller head | |

| Abrasive flow | 4×250 kg/min |

| Elevator | |

Lifting capacity | 80 t/h |

| Separator | |

| Separation capacity | 80 t/h |

| Separation area wind speed | 4-5 m/s |

| Screw conveyor | |

| Conveyor capacity | 80 t/h |

| Feeding | |

| Feeding system | QM pneumatic valve |

| Quantity | 4 sets |

| Dust removal system | |

| Main air volume | 13000 m3/h |

| Power | 11 kW |

| Dust removal method | bag dust removal |

| Total power | |

| Impeller head | 4×15 kW |

| Elevator | 5.5 kW |

| Spiral conveyor | 4 kW |

| Fan | 11 kW |

| Electric feeding | 2.2 kW |

| Total power consumption | approx. 62 kW |

The principle of operation and design characteristics of the shot blasting machine

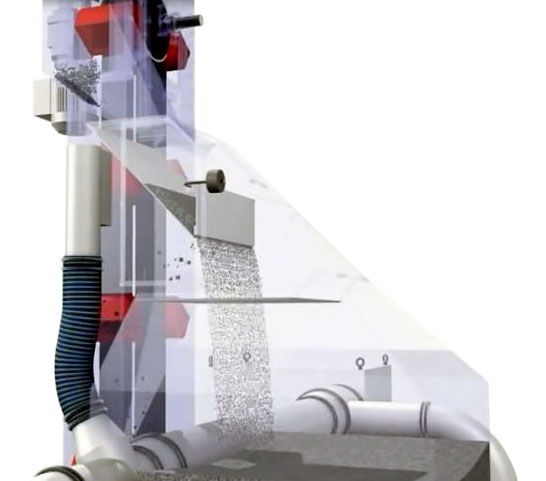

The main functional components of the unit are cleaning room, wire guide device, shot blasting device, projectile circulation system (including elevator, separator, screw conveyor and flow adjustment device), purging mechanism, dust removal system, electrical control system, etc.

The machine for continuous feeding of highly efficient, continuous operation wire traction, the external force after straightening machine coarse pose, send into body mass ejection area of cleaning machine room, the body has been heavily populated the projectile hit with friction, make its scale, rust layer and its dirt falls off quickly, wire surface is bright and clean surface with certain roughness.

The projectile is transported by the recovery screw to the projectile circulation system. During the cleaning process, the pellet dust mixture dropped will be collected in the lower part of the hoist through the chamber funnel and the vertical and horizontal spiral conveyor, and then promoted to the separator on the upper part of the machine.

The purified pellets after separation will fall into the hopper of the separator and be used for shot blasting. The dust generated in the shot blasting cleaning is sent to the dust removal system by the exhaust duct, and the purified net gas is discharged into the atmosphere, while the granular dust is captured and collected.

Equipment composition and structural characteristics

The machine is composed of shot blasting cleaning room, shot blasting device assembly, shot material circulation purification system, hook system, dust removal system and electrical control part. Most of the welding parts of the machine are shot blasting to improve the rust resistance and film adhesion.

Blasting chamber

The cleaning room is a box-shaped welding structure with large cavity plate, and the inner wall of the chamber is lined with wear-resistant protective plate. The cleaning operation is carried out in a closed cavity. The wear-resistant protection plate protects the wall of the chamber from wear and tear, and prolongs the service life of the chamber.

Make full use of the bounce function of the projectile, continue to effectively hit the wire surface, is conducive to improve the cleaning quality and cleaning efficiency.

The cleaning room is equipped with a spacious maintenance door to facilitate maintenance and replacement of indoor wearing parts. The safety interlock switch is installed above the door, and the shot blasting device can only be started after the door is closed.

Clean the indoor wear-resisting protective plate is connected with wear-resisting covering wrap-cast nut bolt, protect the bolt head is not easy to damage, easy to disassemble and replace.

Equipped with 4 external shot blasting machines, each section of the wire can withstand more than two shots.

The box body of blasting room should be made to ensure the dimensional accuracy, the chamber body is thickened with heavy frame structure and has sufficient strength and steel, shot blasting interior lining with high manganese wear resistant steel rolled steel plate protection plate, wear resistant by the inclusion of cast-nut bolt is firm, the box body is tight, in the case of good lining plate no sand leakage phenomenon, the size of the box door to meet the convenience of personnel access, lining plate installation and sealing curtain installation and easy replacement.

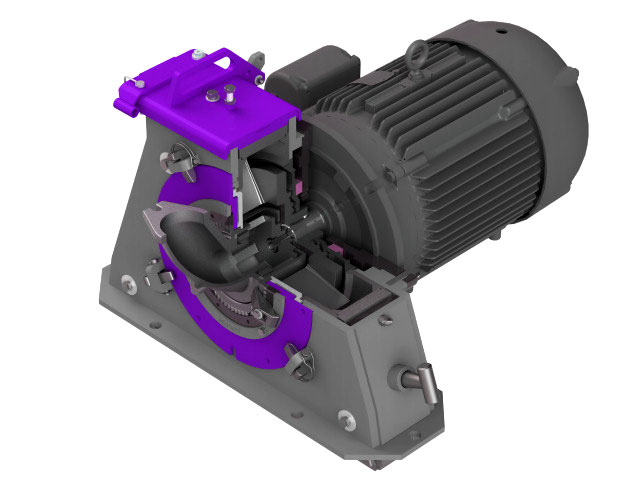

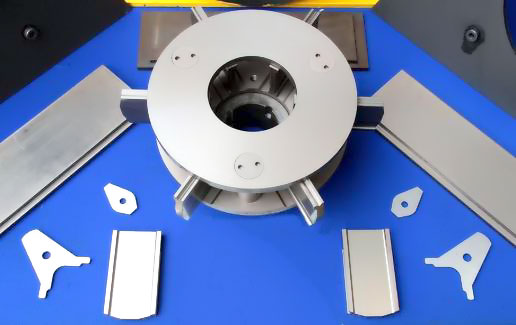

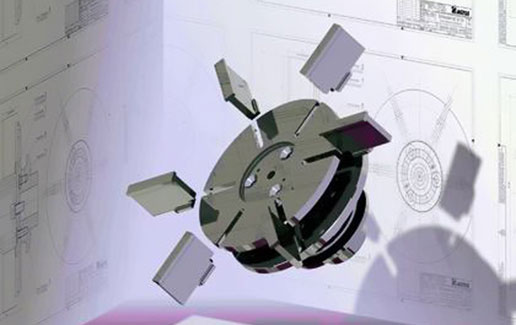

Shot blast impeller

An impeller is designed to meter the stream of shot thrown onto the blade. It gives the initial acceleration to the fraction.

This machine altogether has 4 sets impeller head. In this shot blasting machine blade, pellet wheel, control cage, etc., are all made of tool steel processing.

Blade life: 2000 hours, pellet wheel, control cage and the guard is in commonly, 2000 hours, impeller life is more than 6000 hours.

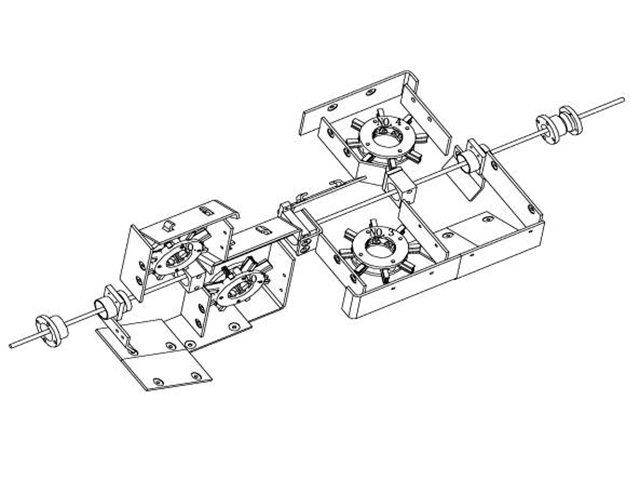

Spiral conveyor

The spiral conveyor is composed of cycloidal gear reducer, screw shaft, conveying cover, bearing with seat, etc. It transports the projectile collected from the bottom hopper to the bucket elevator.

This part is an important part of the device's projectile circulation system. The spiral blade is made of 16Mn material, and its inner and outer circles are stretched after processing by special technology. The pitch and outer circle dimensions are very accurate, which improves the life of the spiral.

Bucket elevator

The bucket elevator is composed of cycloidal pinwheel reducer, upper and lower rollers, conveyor belt, hopper, closed barrel and tensioning device.

Using flat belt rotation, centrifugal gravity way of blanking. When working, the hopper fixed on the conveyor belt will scrape up the pellets at the bottom and send the pellets to the top, and then drop the pellets by centrifugal gravity.

The squirrel cage roller not only improves the friction force between the lifting belt and the belt pulley, and avoids the skidding phenomenon of the old type belt pulley, but also reduces the pre-tightening force of the lifting belt to extend its service life. In addition, it prevents the projectile from getting stuck between the wheel and the belt and causing the belt to run off, and the projectile will flow out from the spoke and the belt.

Pneumatic valve

The air control shot gate valve is adopted to control the shot blasting quantity quantitatively, which can avoid the motor burning out and the shot blasting device being blocked due to the general controller's loose closing shot.

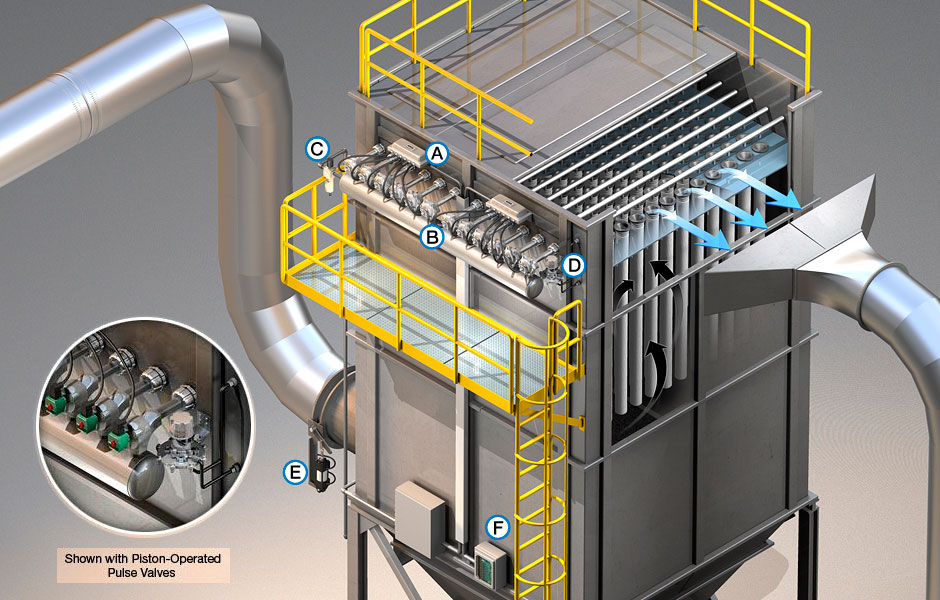

Dust removal system

The dust removal system includes dust collecting box, pulsed cloth bag type dust collector, multi-tube dust collector, fan, connecting pipe between dust collector and main engine, etc.

This equipment adopts the pulse bag filter adopts the pulse counter blowing ash removal method, gas consumption is small, uniform air flow, soot cleaning effect is good, reach more than 99% dust removal efficiency, emissions 30 mg/m3, or less dust bag adopts precision sewing, needled felt filter materials are main line is equipped with the dust collection box to ensure the projectile were not pulled out.

The equipment has the most modern two-stage dust removal mode: the first dust removal level is the settling chamber for shot, located at the top of the equipment. The settling chamber is an inertial settling chamber in accordance with the principle of aerodynamics.

In addition, we designed a one-way valve in the lower part of the settlement chamber to prevent the formation of pneumatic conveying, which can effectively achieve the projectile settlement, dust removal efficiency of more than 99.9% exhaust emission ≤30 mg/m3.

Shot sand separator

This machine adopts BE full screen separator. The shot sand mixture flowing from the bucket elevator is evenly distributed along the whole length of the separator to form a cascade of shot sand flow. At the same time, the dust removal fan draws air through the tuyere of the separator, and uses the principle of gravity air separation to effectively separate the projectile and metal oxide skin fragments, broken projectile and dust in the flow screen.

The large particle waste flows out from the overflow mouth of the separator projectile, the small projectile and dust flow out from the waste outlet, and the projectile enters the pellet bin for circulation.

Adjusting the gap between the vertical and horizontal adjusting baffle of the separator can improve the height and track of the cloth layer, and combining with adjusting the baffle of the separation area, a good separation effect can be achieved, making the separation efficiency as high as 99%.

Electrical control system

The operating personnel of the whole system can start each functional part in sequence, or may not start a single functional part (such as the hoist) in sequence to test the performance and operation of each related part.

Electrical control system of the machine has the following features:

- The door is interlocked with the shot blasting device. If the door is open, the shot blasting device cannot work.

- Shot blasting device and shot feeding brake interlock, shot blasting device is not open, shot feeding brake is not open.

- Electrical control system is equipped with shot blasting quantity current display and high performance over current protection element.

Shot blasting equipment for continuous wire cleaning in the production workshop