EQUIPMENT FOR WIRE CLEANING

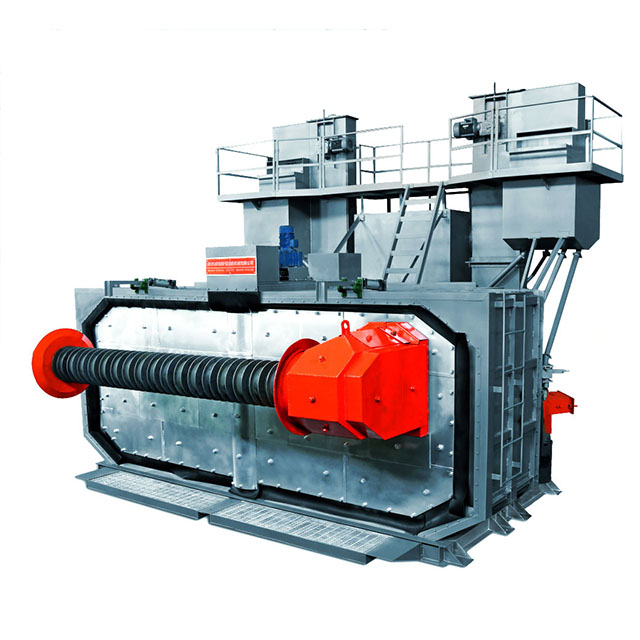

RG-3800 SHOT BLASTING MACHINE FOR WIRE ROD

The shot blasting machine is mainly designed for cleaning wire rods. The machine uses shot blasting cleaning process for descaling the surface of the wire and roughening the surface while also increasing treated metal’s resistance to corrosion. Compared to pickling line, shot blasting cleaning method is more effective, economic, and eco-friendly.

Comparison of the effectiveness of wire cleaning methods

Compared to the pickling method, shot blasting is more efficient ![]() , economical

, economical ![]() and environmentally friendly

and environmentally friendly ![]() .

.

Features of Wire Rods Shot blasting Machine

The equipment uses a unique technology of having a rotating shutter (360°) and a double console crane for wire rod transportation, which significantly increases the production capacity of the equipment

In order to provide a better cleaning, during the shot blasting process the wire goes through a complex of operations: up-down rotation, left-right rotation, forward and reverse rotation. Additionally, the design of the equipment allows both inner and outer sides of the wire surface to get an even shot processing. After shot blasting the wire surface reaches the surface preparation standard of Sa 2.5 (very deep blast cleaning).

Wire specifications

| Wire material | carbon steel, structural steel, carbon tool steel, spring steel, bearing steel, high-speed tool steel, alloy tool steel |

|---|---|

| Wire diameter | Ø6,5 – Ø32 mm |

| Inner rod diameter (min) | Ø800 mm |

| Outer rod diameter (max) | Ø1500 mm |

Maximum load of Wire Rods Shot blasting Machine RG-3800

| Wire rod diameter | 6,5 - 8 mm | 10 - 16 mm | 18 - 28 mm | 30 mm and greater |

|---|---|---|---|---|

| Workpiece weight | Max: 1000 kg | Max: 2000 kg | Max: 2400 kg | Max: 2500 kg |

Transportation method and Productivity

Transportation method: Transportation via double console crane (during shot blasting process console crane can operate in accordance with PLC)

Productivity: 3-6 coils per hour, depending on material quality, size and oxidation level

Effective length: ~3800 mm

Shot Blasting System

| No | Name | Value | Notes | |

|---|---|---|---|---|

| 1 | Shot blasting turbine | Qty | 6 pcs | |

| Capacity | 6 × 32 = 132 kW | |||

| 2 | Shot blasting chamber | Qty | 1 pcs | |

| 4 | Bucket elevator | Qty | 2 pcs | Guomao Reducer Co., Ltd. |

| Reducer | Compact gear reducer | |||

| Capacity | 2 × 4,0 = 8 kW | |||

| 5 | Lower auger conveyor | Qty | 2 pcs | Guomao Reducer Co., Ltd. |

| Reducer | Compact gear reducer | |||

| Capacity | 2 × 2,2 = 4,4 kW | |||

| 6 | Abrasive bead controller | Qty | 6 pcs | |

| Control type | Adjustable | |||

| Control method | Pneumatic | |||

| 7 | Intermediate power | 144,4 kW. | ||

Shot blasting process and principle of operation

The machine is installed in accordance with wire characteristics on the rear and lateral sides of the chamber with six highly efficient shot blasting turbines. The wire is processed at a speed of 78 m/s.

- The equipment includes:

- abrasive bead separation system

- high-strength high-temperature belt type lift

- horizontal conveyor

- two-step cleaning and dust-removal system

- automatic and manual machine interface control systems