WIRE PACKAGING

AUTOMATIC WIRE WINDING AND PACKAGING MACHINE RGW-3

Main functions

- Manual / automatic mode selection

- PLC programmable control system

- HMI interface

- If the width, inner and outer diameter are entered into the PLC, the length of the packing tape and the numbers of winders can be automatically adjusted.

- Packing material can be selected in accordance with customer’s preferences; adjustment of packing tape is also possible upon request.

- Automatic alarm displays messages about errors

- Independent control cabinet

The machine is easy to operate as the system selects the most appropriate packaging options automatically. The C-shaped rotating ring that is made of a cast construction is very strong and stable.

The main unit can be moved left and right to accommodate products with different inner and outer diameters.

Features and Advantages of the Equipment

- The equipment is suitable for wire coils with an external diameter of 2000 mm, an internal diameter of 600 mm, a thickness of 800 mm

- The equipment is made of structural steel.

- PLC control system manufactured by Siemens or Mitsubishi

- Alarm and status management system

- Pneumatic components manufactured by Yadeke

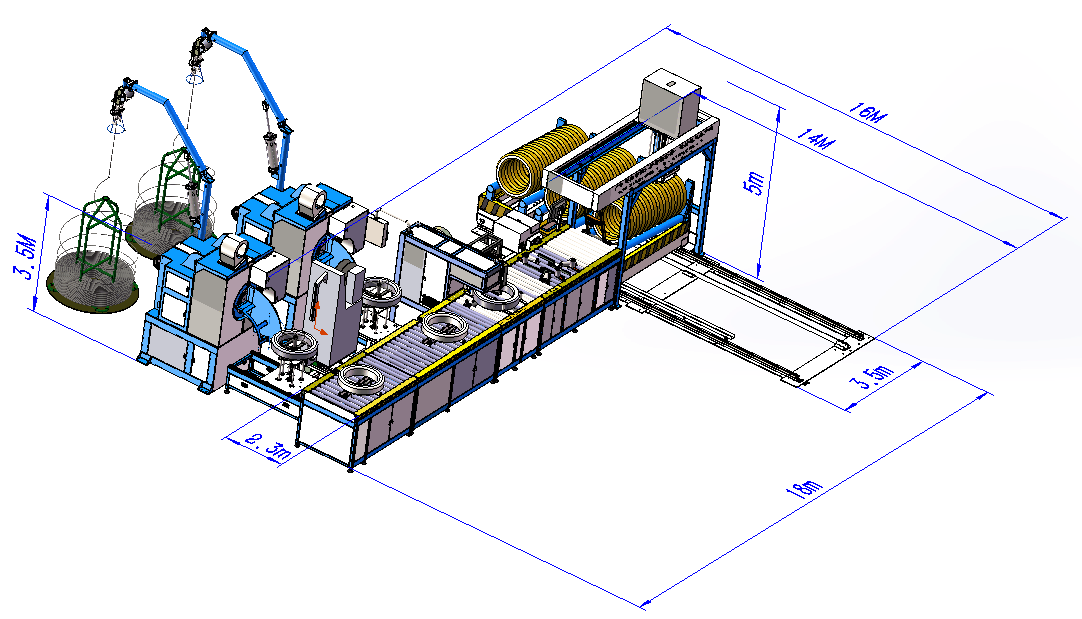

- Equipment width 16 m, length 18 m, height 5 m

- Cost reduction: labor costs can be reduced by more than 90°/o, and packaging material costs can be reduced by 30%

- High productivity: automatic weighing, label printing and labeling can be directly linked to ERP system and generate reports in order to avoid any errors cause by manual input

- Stable and reliable performance, attractive appearance

- Convenience tune-up and operational safety

TECHNICAL SPECIFICATIONS

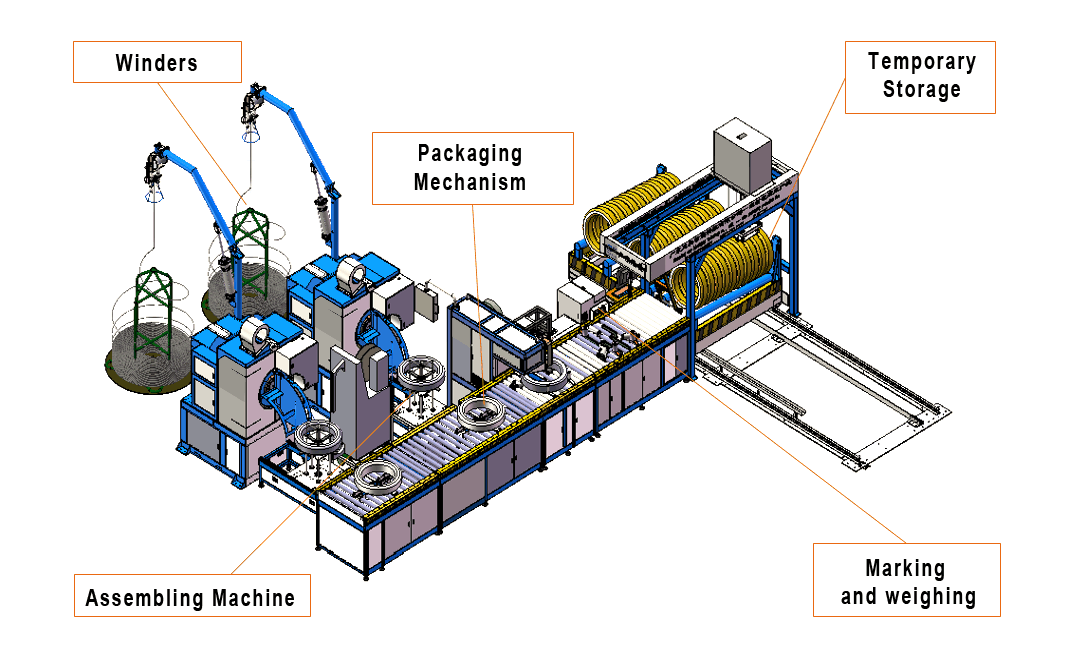

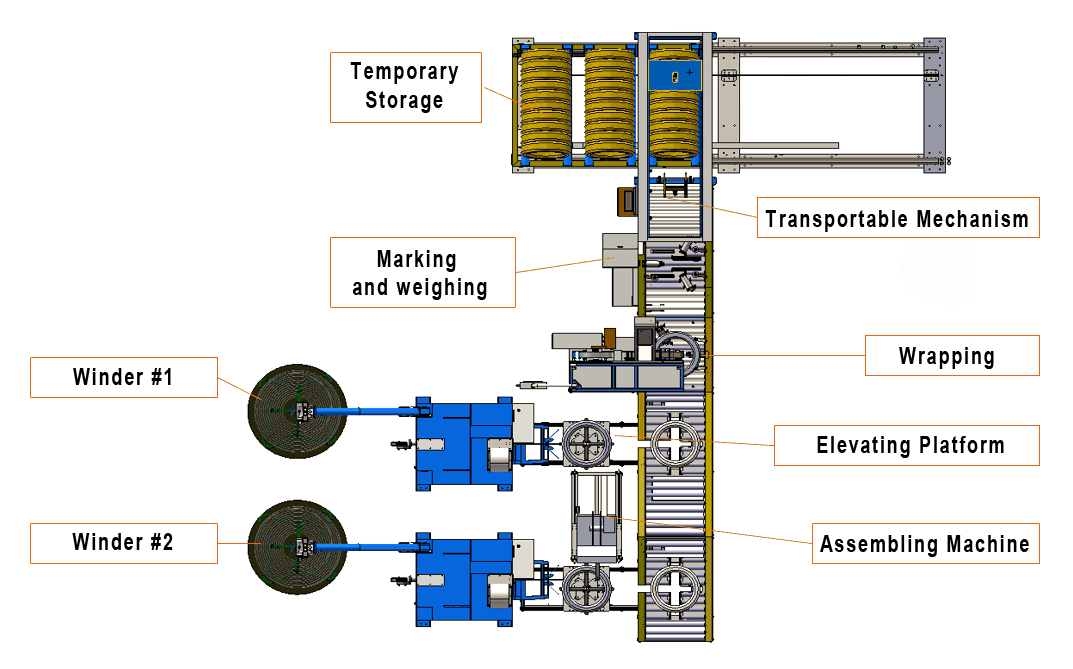

The automatic wire winding and packaging machine has a modular structure and is equipped with a number of functions:

- Wire coil calibration, weighing and winding

- Coil transportation and packaging

- Real-time label printing and labeling

- Material classification

- Temporary storage

- Data entry

- Unloading

The machine is simple and efficient to assemble and can be assembled in accordance with customer’s requirements.

Process flows

![]()

![]()

![]()

![]()

Configuration of equipment for winding and packing wire

Equipment dimensions

Finished products

Parameters of automatic wire winding and packaging machine

| Model | RGW-3 |

|---|---|

| Type | Horizontal |

| Equipment size | length 18 m, width 16 m, height 5 m |

| Feed ring size (standard) | 720 mm х 500 mm х 210 mm |

| Product width | 50-100 mm |

| Inner diameter | 500 mm |

| Outer diameter | 750 mm |

| Length | 210 mm |

| Weight | 50 - 150 kg |

| Ring speed | 10 - 100 r/min |

| Roller speed | 1 - 3 m/min |

| Packaging | Winding film/ antirust film: width 60 - 90 mm, paper core inner diameter 50 mm, outer diameter 100 - 150 mm. Braided tape/ composite paper tape/ wrinkled paper tape etc.: width 60 - 90 mm, paper core inner diameter 55 mm, outer diameter 100 - 150 mm |

| Voltage | AC 220/380V, 50/60 Hz |