EQUIPMENT FOR THE MANUFACTURING OF NAILS

ROOFING NAILS MAKING EQUIPMENT

Roofing Nail Making Equipment consists of Cap Making Machine for Roofing Nails и Nail Making Machine RZ94-4C.

In order to deburr, lubricate and give nails the desired finish you will need a Nail Polishing Machine.

A Galvanizing Line may be required to improve the nail appearance and surface protection.

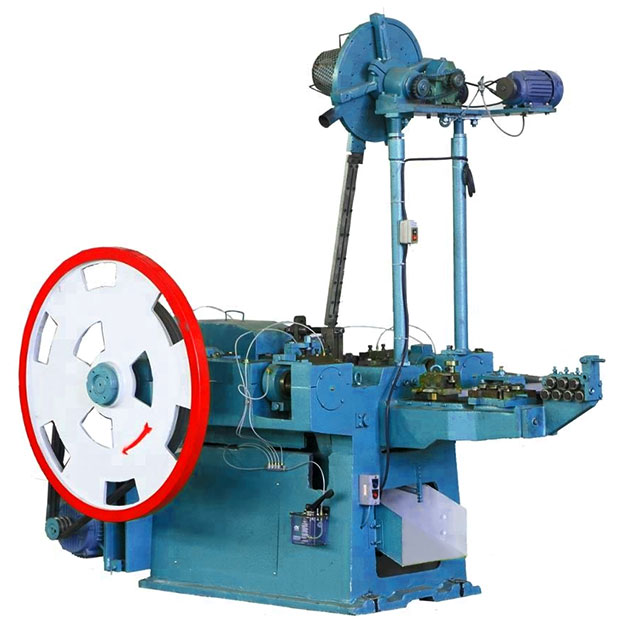

Automatic roofing nail making equipment RZ94-4C

Description of equipment for manufacturing roofing nails

Nail Making Machine RZ94-4C is a compact stationary high-speed automatic electromechanical device of continuous action of a plunger type. It is designed for metalworking enterprises that are closely connected with the mass production of wire products.

Nail Making Machine RZ94-4C can sometimes be a continuation of the wire drawing line, but more often it works as an autonomous machine. The machine for roofing nails manufacture can produce not only conventional roofing nails, but also roofing thread nails. Automatic assembly of roofing nails starts after launching the equipment. After assembly, the nails are automatically unloaded.

The wire is fed into the open operating area from the coil or directly from the drawing mill. After that, it is aligned on vertical and horizontal rulers made of high-strength rollers that are installed in a staggered pattern. The drive system covers wire feeding, wire clamping, wire cutting and cap embossing. The mechanics include one main crank and two side shafts. The main axis is directly driven by the engine. Additionally, two side shafts which are separately used to control parts of the cutter, are pulled through four bevel gears. Finished nails are automatically thrown through the ejector onto an inclined pallet.

Nail Making Machine RZ94-4C is controlled by a simple remote control.

Specifications of Nails Making Machine RZ94-4C

| Maximum Nail Diameter | mm | 4.5 |

|---|---|---|

| Minimum Nail Diameter | mm | 2.8 |

| Maximum Nail Length | mm | 90 |

| Minimum Nail Length | mm | 35 |

| Performance | pcs / min | 110 - 130 |

| Power | kW | 4 |

| Overall Dimensions | mm | 2350 × 1512 × 2000 |

| Weight of equipment | kg | 2100 |

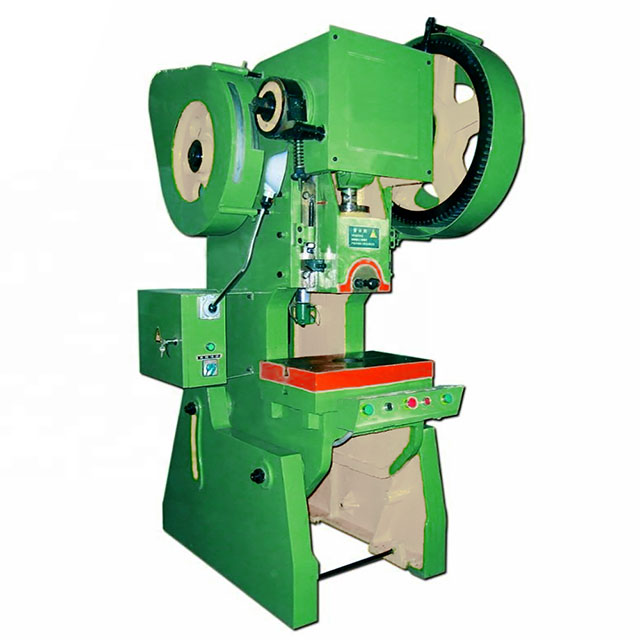

Cap Making Machine for Roofing Nails

This press machine is designed for the production of roofing and upholstery caps. The machine has a cast structure and a variable angle of inclination, which provides the convenience of stamping. The automatic press has an advanced mechanism, high performance and is easy to handle.

This equipment manufactures 6 nail caps in one pressing turn. Working speed of the machine is 55 times per minute. Nail caps are formed from steel strip and have a uniform surface amd high quality. Cap making machine does not take much space, has low noise and low vibration levels.

Specifications of Cap Making Machine for Roofing Nails

| Performance | 300 pcs/min (55 batch x 6 pcs in minute) |

|---|---|

| Motor power | 2.2 kW |

| Overall Dimensions | 1350 × 1050 × 2200 mm |

| Weight of equipment | 1500 kg |

Nail Polishing Machine

The Polishing Machine is used for deburring, lubricating and achieving the desired finish of a nail.

Nail Polishing Machine consists of a loading device, tumbling drum, a drum designed for screening out sawdust and vibrating screens.

ОCleaning of manufactured products is carried out with the help of sifted dry sawdust made of hard wood from transverse cutting. It polishes the nails, cleans them of sharp edges and oil stains formed after rolling, and removes rust and unevenness. Also, if desired, oil can be added to the sawdust.

After the nails are processed, the product is ready for sale.

After polishing nails become brighter and acquire anti-corrosion properties.

See more details about the Nail Polishing Machine

Electro Galvanized Line for Wire Nails and Screw

The nail galvanizing line is an auxiliary equipment in the manufacture of roofing nails, designed to improve the external characteristics and protect the nail surface by means of electroplating processing. This electroplating equipment is used for galvanizing finished roofing nails, as well as other types of wire nails, screws, etc.

Electroplating is the most effective method of protecting metal parts from corrosion. Galvanic drums made of polyethylene are used to process smaller parts.

The advantage of this type of treatment is a 2 times increased production of threated parts compared to pendants. Other advantages of galvanizing in polyethylene drums are resistance to chemically aggressive substances used in this process, which increases the service life of the drum.

Technical Specifications of Electro Galvanized Line

| PE drum capacity | 120 - 150 kg |

| Drum size | 1100 x 500 mm |

| Rectifier | 2000 kVA |

| Total Motor power | 3.75 kW |

| Galvanizing time | 50 min/time (3 drums/time) |

| Main Parts and production process |

|