OPTICAL QUALITY SORTING EQUIPMENT FOR FASTENERS, METALWARE AND PARTS

General Information on Fastener Inspection Equipment EDDY CURRENT SORTING EQUIPMENT CONVEYOR SORTING EQUIPMENT GLASS DIAL SORTING EQUIPMENT ROTARY DISK SORTING EQUIPMENT INSPECTION EQUIPMENT WITH 360° ROTATION PERIPHERAL SORTING EQUIPMENT

PECULIARITIES OF OPTICAL QUALITY SORTING EQUIPMENT FOR FASTENERS, METALWARE AND PARTS

Why do so many partners from around the world choose our equipment?

Optical quality sorting equipment for fasteners, metalware and parts, proposed of Taiwan Metiz Alliance has a number of advantages, combining cutting-edge design, the quality of diagnosis and affordability.

Benefits include:

- High speed testing: depending on parameters of fasteners, the machine can check up to 1,000 units of products per minute.

- Wide range of testable products: screws, nuts, bolts, fasteners.

- A wide range of test surfaces of products: more than 60 geometric forms and material features.

- Modern software: developed by experts of the manufacturer.

Components of electronics of the test equipment (digital cameras for production purposes, computers, appliances generate eddy currents of induction, servo motors, programmable logic controllers, and so on) are produced in Japan, Germany and Taiwan.

Sample of test products

Parameters of grading and automatic quality test for fasteners

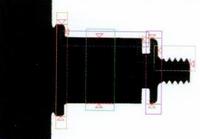

The distance and the shape of the thread pitch

Thread Level

Formation of a bottom product / diameter / length

Tapered end / twists / notches

Damage to the bolt / groove depth

Couplings

Ineffective length

Parameters length / height

Designated welding

Designated welding

Thread damage

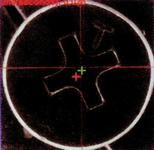

Markings on the front of the product

Alignment / roundness

Auto focus

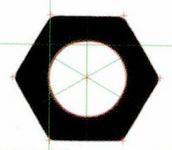

Number of teeth / distance between the teeth

The distance and the size of the holes

Cracks

Diameter / width

Marking fasteners

Availability of thread

Cracks on the black screws

Damage to the thread

Damage to the thread

Cracks on the screws

The presence of notches

The presence of notches

Cracks on the screws of zinc

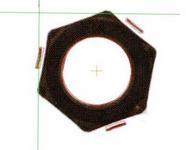

External inspection of nuts

The height and width of the heads of screws

Chamfers / bevels

External inspection of nuts

Surface defects

Cracks

Designated welding

Cracks on the screws of zinc

Internal inspection of the threads on nuts