COLD FORMING EQUIPMENT FOR SELF TAPPING SCREWS AND RIVETS

SELF TAPPING SCREWS PRODUCTION

- Full self-tapping screw production cycle (for reference).

- The table of conformity of products and equipment

- Equipment Gallery

- Thread rolling machines for self tapping screws

Taiwan Fastener Alliance offers a wide range of cold heading and thread rolling equipment for the production of self-tapping screws. In order to correctly select the model and set of equipment for self-tapping screws, which will guarantee the output of products for which there is a great demand in the market, you must specify:

- The diameter of the product.

- The length of the produced product.

- Specify the presence of a drill.

- Specify the type of screw, its purpose (wood, metal, concrete, roofing, window).

- Give drawing, photo or specify DIN or GOST standard.

EQUIPMENT FOR COLD HEADING SELF TAPPING SCREWS IN A PROTECTION COVER

- Thanks to the fully sealed design, the cased cold heading machines have the lowest noise level and the highest environmental performance.

- The service life of the cold forming machines and machine tools is much longer due to the exclusion of dust or foreign objects entering the machine.

- Cold heading equipment with a protective cover guarantees maximum protection of the operating personnel. This is ensured due to several design features of the machines: a closed oil tank completely excludes ignition from the effects of an open flame or sparks in the workshop, safety sensors will perform an emergency shutdown of the equipment in the event of unauthorized access inside the machines and in the event of abnormal situations in operation, connecting the exhaust ventilation to the machine removes the arising in the process of cold disembarkation of fumes.

- Advanced control of cold heading parameters.

- Maximum standard and optional configurations.

Complete set of equipment for self tapping screws production

Standard equipment

- 1 set of machine tools

- Wire unwinder

- Automatic counting device

- Work lighting

- Maintenance tools

- Passport

- Operation manual in English

- Electrical cabinet (with protection class IP 64)

Additional equipment (optional)

- Security door with power cut-off and automatic shutdown system (option)

- Inverter (optional)

- The conveyor for chip removal

- Certification CE

A range of cold heading equipment for the production of self-tapping screws and screws

Technical characteristics of equipment for production of self-tapping screws and bolts

| Model | Max. blank diameter | Max.blank length | The stroke length of the slide | Capacity, pcs./min. | Diameter of the main die | Diameter of the cutting die | The first punch | The second punch | Power of main engine | Oil pump | Dimensions, L×W×H, сm | Net weight, kg | Gross Weight , kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-2C | 0.8~3 mm | 24 mm | 38 mm | 190~220 | 20 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 165×110×156 | 860 | 930 |

| RA-5.5C | 2~3.5 mm | 28 mm | 46 mm | 200~250 | 25 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 175×115×185 | 980 | 1050 |

| RA-10C | 2~4 mm | 32 mm | 58 mm | 190~220 | 30 mm | 15 mm | 24 mm | 20 mm | 2 HP | ¼ HP | 185×130×200 | 1060 | 1360 |

| RA-15C | 4~5 mm | 64 mm | 92 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 198×130×175 | 1930 | 2130 |

| RA-15C | 4~5 mm | 76 mm | 110 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 198×130×175 | 2030 | 2230 |

| RA-20C | 4~6 mm | 76 mm | 124 mm | 80~100 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 240×140×150 | 2775 | 2280 |

| RA-20C | 4~6 mm | 102 mm | 160 mm | 80~100 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 265×140×188 | 3250 | 3400 |

| RA-25C | 4~8 mm | 152 mm | 160 mm | 65~85 | 60 mm | 32 mm | 38 mm | 38 mm | 7 ½ HP | ¼ HP | 350×160×180 | 4500 | 4650 |

COLD HEADING EQUIPMENT FOR SELF TAPPING SCREWS IN A SEMI-PROTECTION COVER

Models of cold heading equipment for the production of screws with semi-protection cover is relatively easier to operate compared to models in a protective cover, and more environmentally friendly. Currently, this equipment is the most popular choice among our clients. Cold forging equipment for the semi-protective cover are represented by machines of large and medium size, ideal for the production of high-quality large and microscopic screws used in machinery, automotive, photo-electronics, precision electronics (iPhone), electrical engineering, automotive industry and others. Fasteners of this equipment can withstand shock and vibration.

Technical characteristics of equipment for production of self tapping screws and bolts

| Model | Max.blank diameter | Max.blank length | The stroke length of the slide | Performance, pcs./min. | Diameter of the main die | Diameter of the cutting die | The first punch | The second punch | Drive power | Oil pump | Dimensions L×W×H, mm | Net weight, kg | Gross weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-5S | 0.8-3 mm | 24 mm | 38 mm | 170~200 | 20 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 1650×1100×1560 | 820 | 880 |

| RA-5.5S | 2-3.5 mm | 28 mm | 46 mm | 200~250 | 25 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 1750×1150×1550 | 980 | 1050 |

| RA-10S | 2-4 mm | 32 mm | 58 mm | 190~220 | 30 mm | 15 mm | 24 mm | 20 mm | 2 HP | ¼ HP | 1850×1300×1720 | 1050 | 1160 |

| RA-15S | 4-5 mm | 64 mm | 92 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 2100×1100×1320 | 1750 | 1840 |

| RA-15S | 4-5 mm | 76 mm | 110 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 2100×1100×1320 | 1860 | 1980 |

| RA-20S | 4-6 mm | 76 mm | 124 mm | 90~110 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 2400×1400×1500 | 2645 | 2750 |

| RA-20S | 4-6 mm | 102 mm | 156 mm | 80~100 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 2650×1500×1500 | 3210 | 3360 |

EQUIPMENT FOR COLD HEADING (PRODUCTION) OF SELF TAPPING SCREWS WITHOUT A PROTECTION COVER

/RA-5.jpg)

/RA-5-5.jpg)

/RA-10.jpg)

/RA-15.jpg)

/RA-20.jpg)

Technical Specification of Equipment for the production of self tapping screws and bolts

| Model | Max.blank diameter | Max.blank length | The stroke length of the slide | Performance, pcs./min. | Diameter of the main die | Diameter of the cutting die | The first punch | The second punch | Drive power | Oil pump | Dimensions L×W×H, mm | Net weight, kg | Gross weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-5 | 0.8-3 mm | 24 mm | 38 mm | 170~200 | 20 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 1370×840×1020 | 500 | 560 |

| RA-5.5 | 2-3.5 mm | 28 mm | 46 mm | 200~250 | 25 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 1750×1100×1600 | 780 | 860 |

| RA-10 | 2-4 mm | 32 mm | 58 mm | 190~220 | 30 mm | 15 mm | 24 mm | 20 mm | 2 HP | ¼ HP | 1690×1090×1260 | 960 | 1060 |

| RA-15 | 4-5 mm | 64 mm | 92 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 2100×1100×1320 | 1640 | 1750 |

| RA-15 | 4-5 mm | 76 mm | 110 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 2100×1100×1320 | 1750 | 1860 |

| RA-20 | 4-6 mm | 76 mm | 124 mm | 90~110 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 2400×1400×1500 | 2400 | 2500 |

| RA-20 | 4-6 mm | 102 mm | 156 mm | 90~110 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 2400×1400×1500 | 2400 | 2500 |

| RA-25 | 4-8 mm | 102 mm | 160 mm | 65~85 | 60 mm | 32 mm | 38 mm | 38 mm | 7 ½ HP | ¼ HP | 3500×1510×1350 | 4000 | 4150 |

| RA-30 | 10 mm | 152 mm | 230 mm | 52~60 | 80 mm | 40 mm | 55 mm | 55 mm | 15 HP | ½ HP | 4450×1740×1510 | 7000 | 7000 |

| RA-40 | 13 mm | 152 mm | 230 mm | 50~60 | 98 mm | 48 mm | 68 mm | 68 mm | 30 HP | ½ HP | 5000×2050×1800 | 12000 | 12000 |

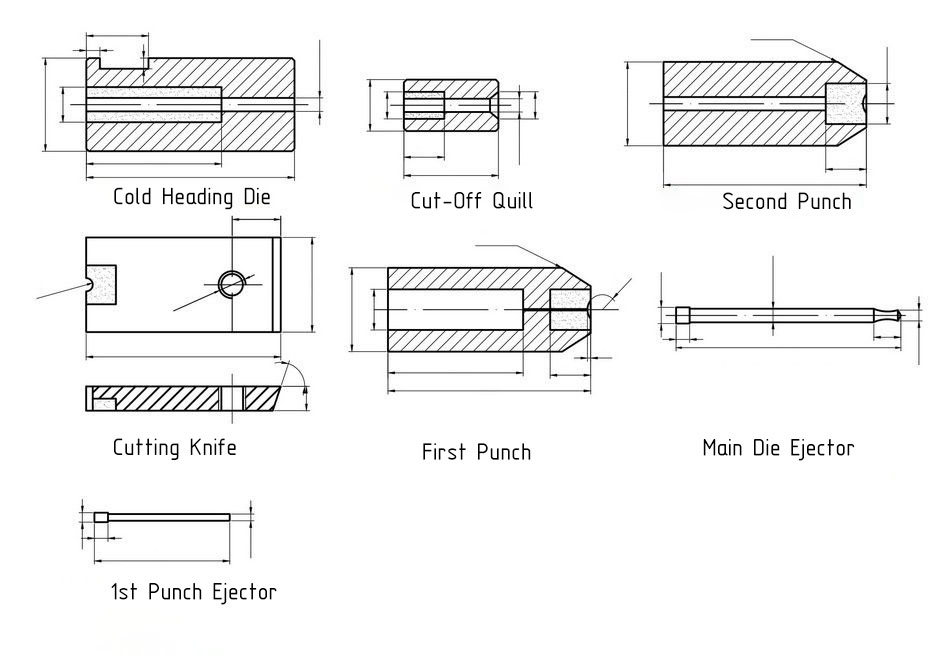

ORDER-MADE COLD HEADING TOOL FOR MAKING SCREWS, SELF-TAPING SCREWS AND RIVETS

We have the ability to develop machine tools and accessories according to the drawings of finished products and the technical requirements of the customer. To do this, it is necessary to clarify the size of the fittings for the equipment, the model of the cold heading machines used and the diameter of the wire used for the upsetting of fasteners, hardware and parts).

FULL SELF-TAPPING SCREW PRODUCTION CYCLE (FOR REFERENCE)

The wire goes through several stages of processing before becoming a self-tapping screw. Formation of the workpiece by means of a cold heading machine. At this stage, the product acquires the required length, tip and head. The threaded rod thread is then cut on the thread rolling machine.

Furthermore, in production the additional stage is possible - if the self-tapper has a drill it is necessary to use additional equipment to form the drill.

To improve product quality, surface hardening processes can be added to increase the strength of the product and anticorrosion treatment. The product is then packed and packaged in plastic bags and boxes.

Self-tapping Screw Cold Heading Technology

The production of blanks for self-tapping screw is carried out on two-impact single-position automatic cold heading machines (upsetting machines). The equipment has two punches (roughing and finishing) and one cold heading die.

The prepared wire is installed on the unwinding device and fed through the roller system of the two-plane straightening device into the receiving opening of the shear die. Next, you need to set the adjustable stop to the desired length of the workpiece. After that, the machine is switched on for a working stroke.

The cut-off knife performs a cut and with the presser feet transfers the workpiece to the upsetting position where the workpiece is picked up by the end of the rough punch, pushed into the upsetting die to the front end of the ejector. After that, the pre-stamping of the self-tapping head takes place. The operation forms about 70% of the self-tapping head shape.

At the second stroke of the actuator, the tool head turns about, as a result of which the second punch is set to the upsetting position, which finally forms the screw head (remaining 30% of shape).

During the return stroke of the slider of the cold heading machine, its ejector extracts the stamped blank from the cavity of the cold heading die, after which the cycle is repeated. The stamped workpiece is fed through the tray into the receiving container.