SCREW SLOTTING MACHINES

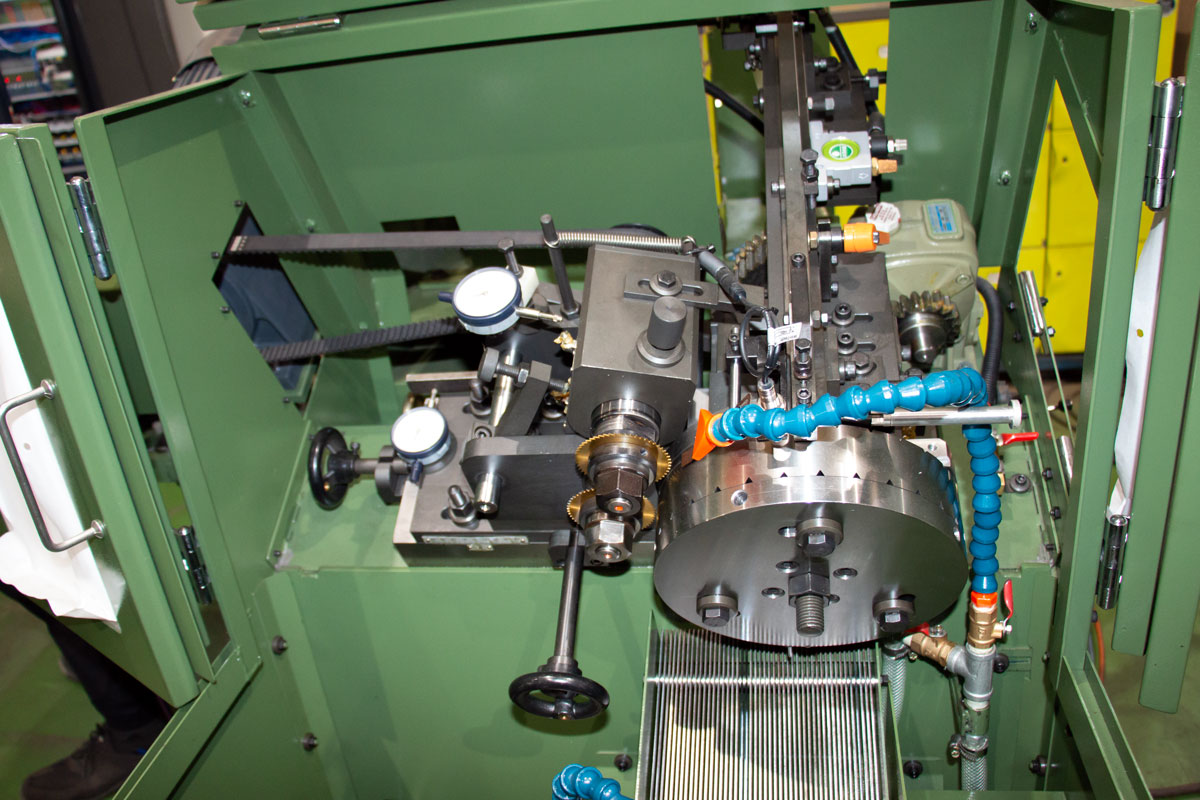

Double Cutter Slotting Machine with Protective Cover

Slotting machine with double cutter in a protective cover is used for screws and small fasteners, the production of which excludes the technology of forming splines by cold heading.

Metal cutting machine for slotting. Straight-sided splines and involute profile splines on shafts are formed by a milling cutter by rolling. The cutter rotates and simultaneously performs a feed motion (moving along the axis of the workpiece), the workpiece also rotates with a frequency depending on the number of splines formed.

The boring process is highly accurate, stable and occurs at high speeds. The equipment does not make much noise.

After two step boring, chips are removed automatically, which eliminates the formation of burrs on the head of fasteners. Fastener splines of small diameters are usually milled in one pass, large diameters in two passes.

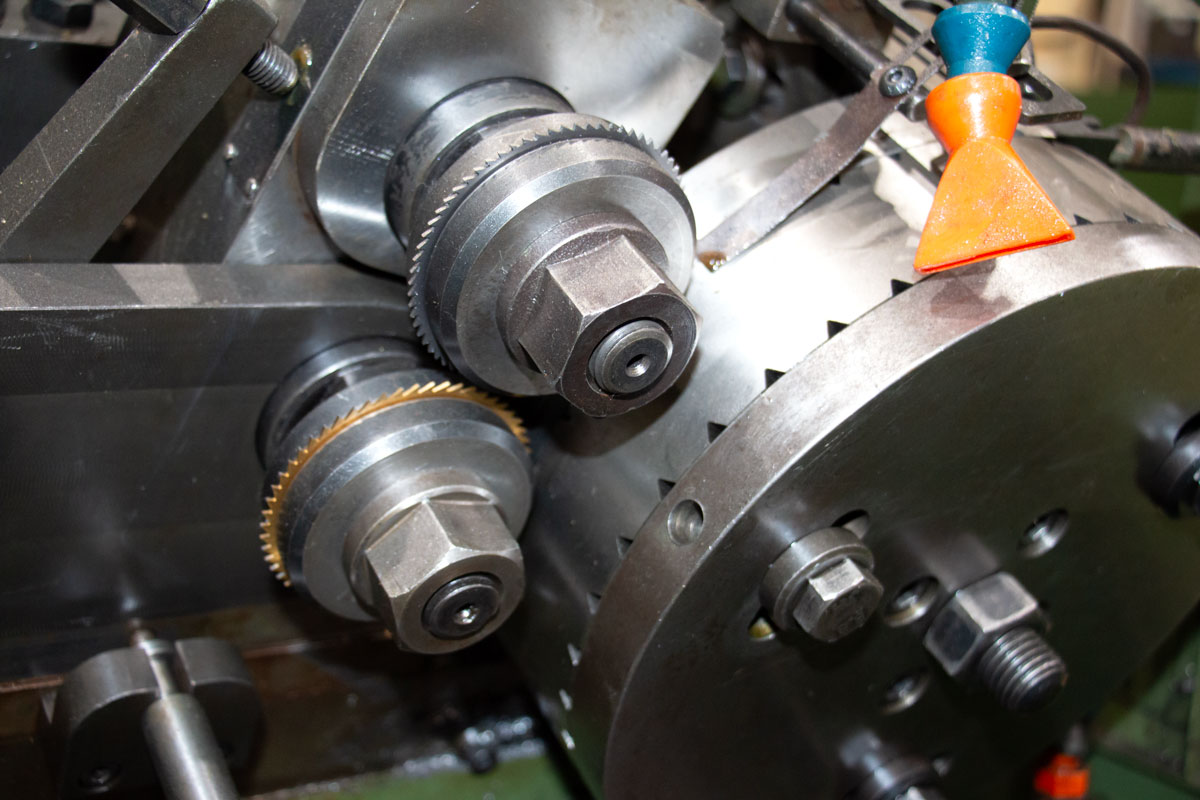

Double Cutter for slotting Screw Head

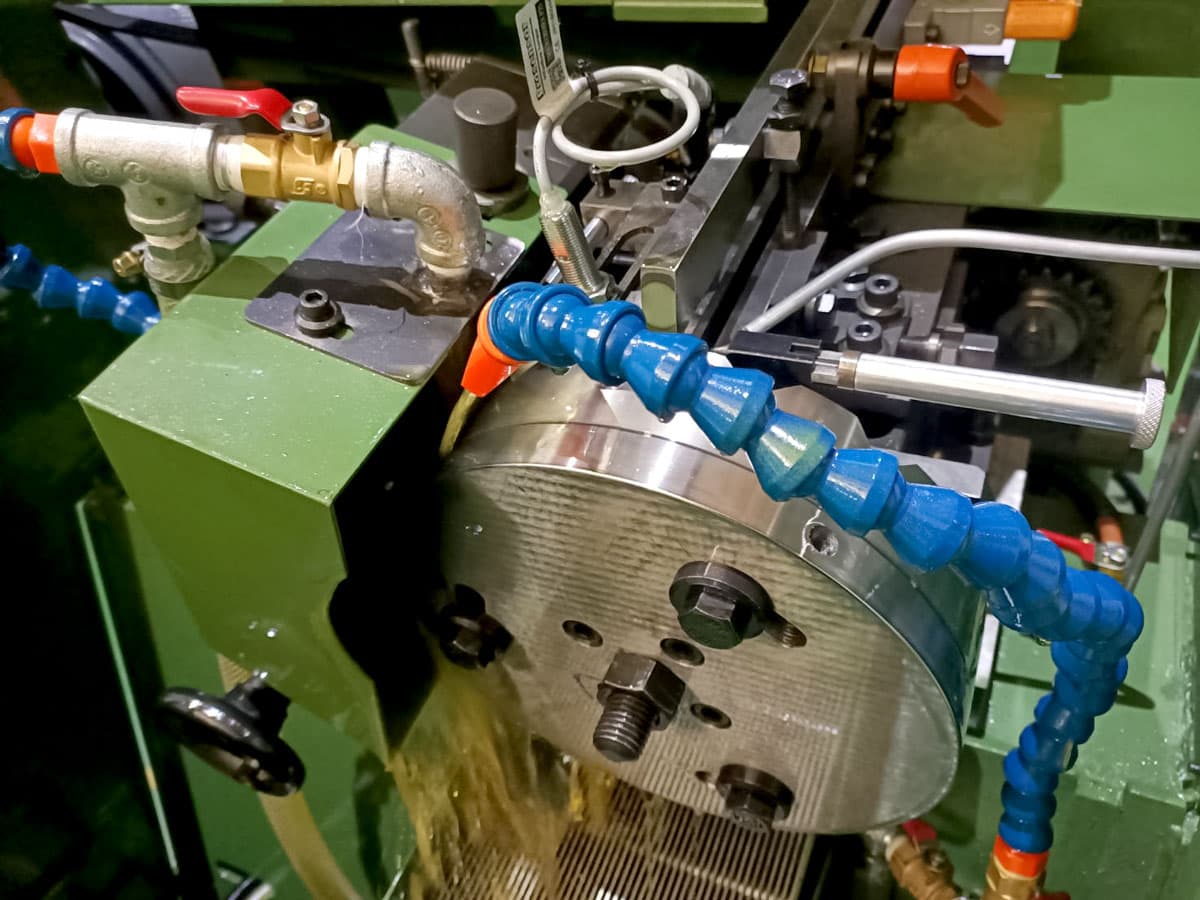

Workpiece gripper

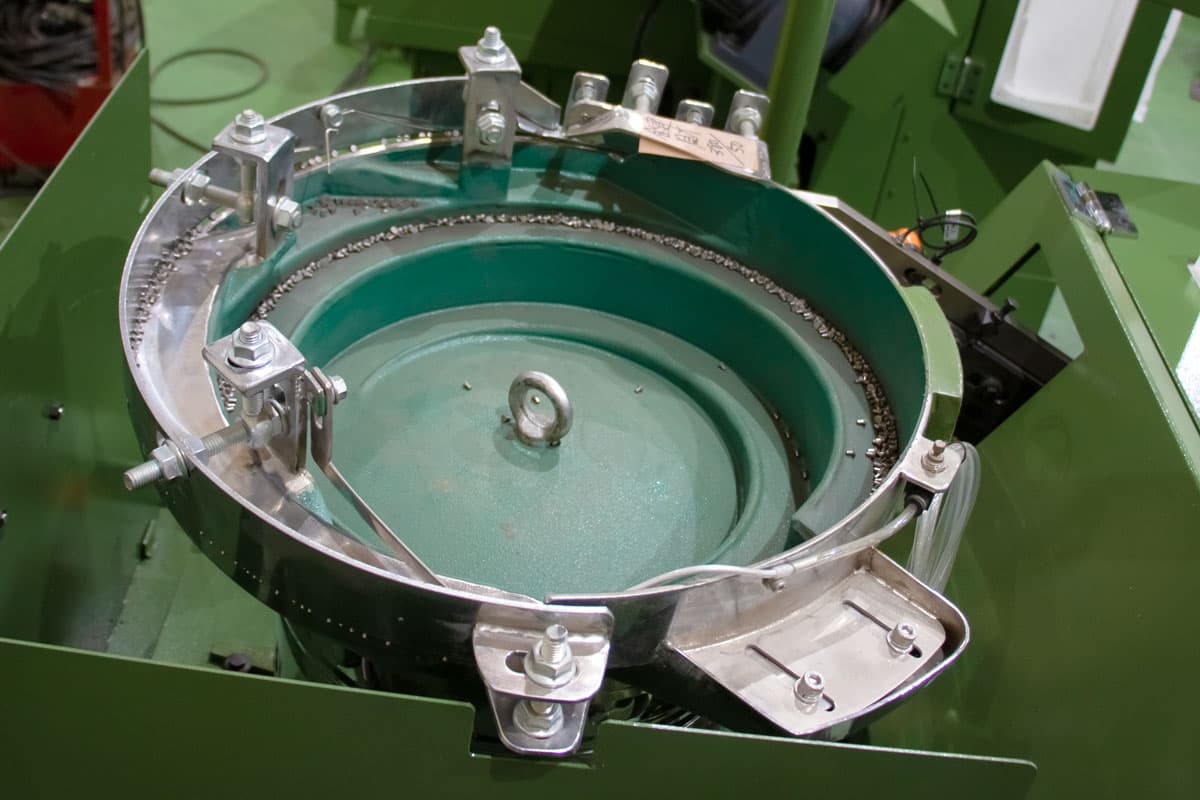

Vibratory Feed Bowl

For workpieces of different sizes, vibrating bowls of the appropriate diameter are used:

- Ø300 / Ø400 for M1 - M3

- Ø520 for M3 - M6

- Ø620 for M6 - M10

The minimum length of the product is 4 mm.

Slotting Machine Control Panel

Electrical equipment of the slot milling machine

Slot milling machine is controlled by a controller, one operator is able to operate more than ten machines.

Technical specification of slot milling machines

| Model | Screw Diameter, mm | Screw Length, mm | Maximum Output, pcs/min | Motor Power, HP |

|---|---|---|---|---|

| AR-3C | 1.4-3 | 4-25 | 70-110 | 2 |

| AR-5D | 1.6-6 | 5-45 | 40-80 | 2 |

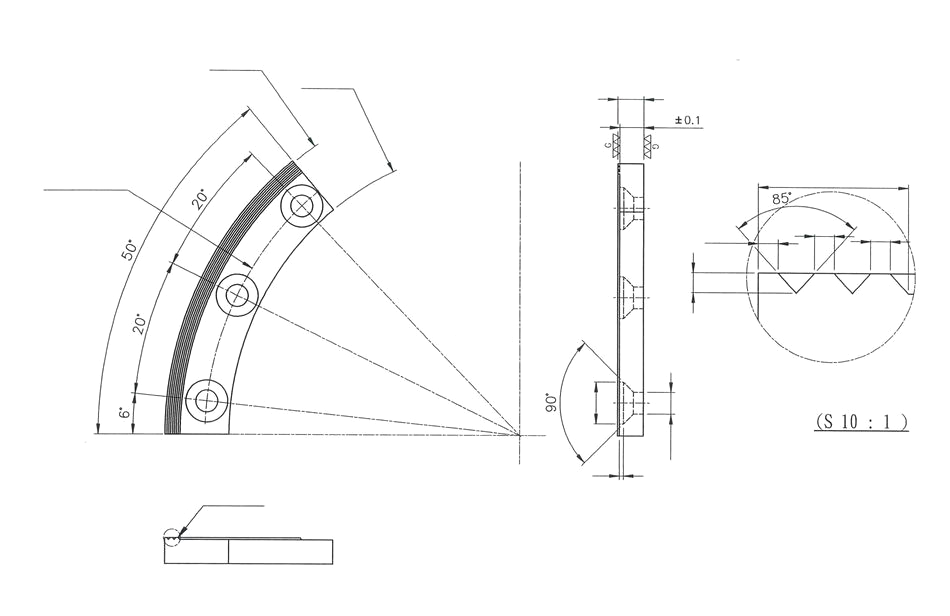

Tools for Slotting Machine

We have the ability to develop tools according to the drawings of finished products and the customer’s technical requirements. Including tools for slotting machines.