THREAD ROLLING MACHINES FOR THE FASTENERS INDUSTRY

THREAD ROLLING MACHINES FOR MICROTHREADING ON MICROSCREWS

Thread-rolling machines for micro-threading produce thread rolling on micro fasteners with a diameter of 0.6 - 2.6 mm, a length of 0.7 - 25 mm. Such mini and micro screws are widely used in electronics and electrical engineering, instrumentation, medical equipment, household appliances and office equipment. The productivity of the equipment reaches up to 250 pcs/min.

Micro thread rolling machine AR-001FC

| Model | Max. Blank Diameter, mm | Max. Blank Length, mm | Output capacity, pcs/min | Standard tool sizes, mm | Main motor power | Machine Sizes, L × W × H, cm | Net weight approx., kg | Gross weight approx., kg | Feeding Type |

|---|---|---|---|---|---|---|---|---|---|

| AR-001FC | 0.8 - 2.0 | 0.8 - 10 | 100 - 150 | 15 × 20 × 45~55 | 1 HP | 145 × 122 × 169 | 710 | 880 | Flat |

Micro screw thread rolling machine RG-00L2

The RG-00L2 thread rolling machine is designed for precision micro-thread rolling on microscrew products with an outer diameter of M0.6 to M1.7 and a length of 0.7 to 6 mm.

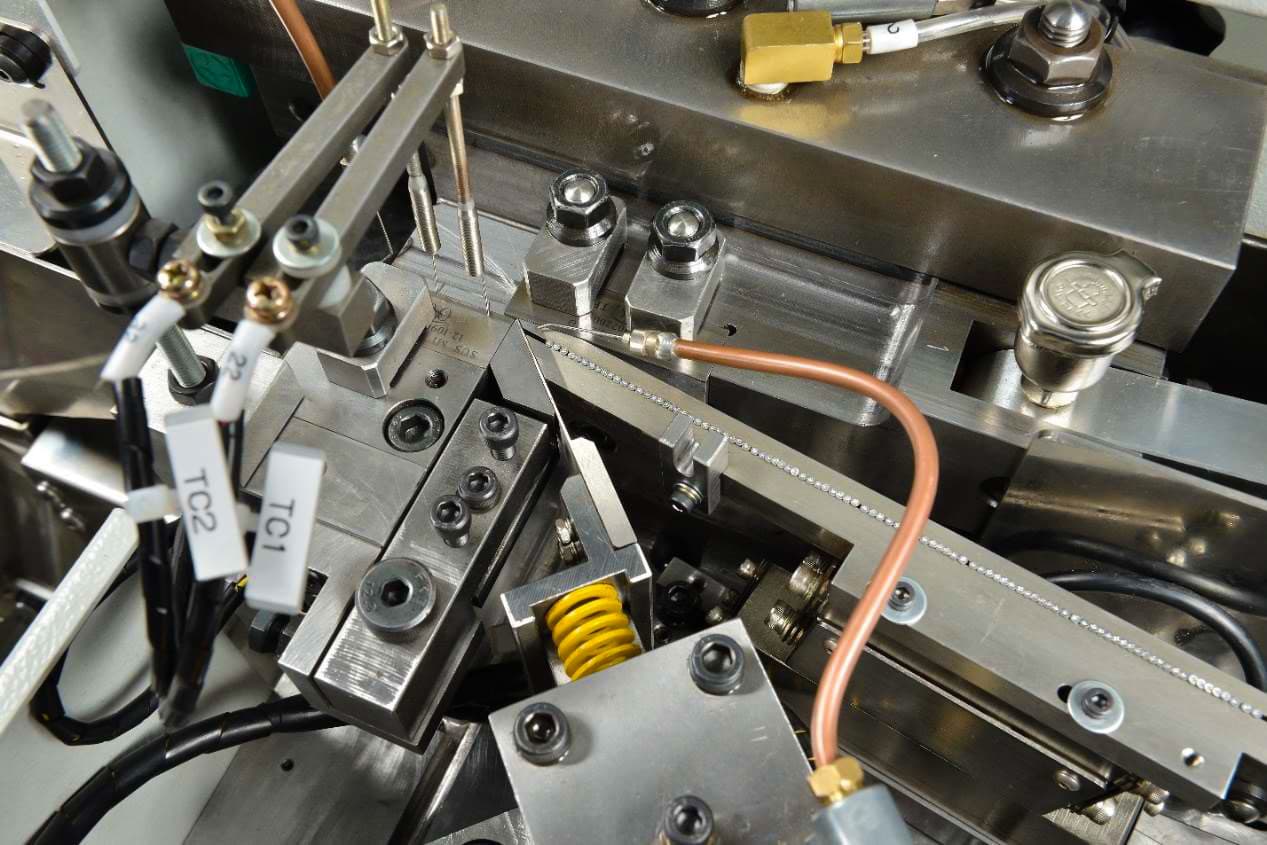

Microscrew blanks are fed into the microthread rolling unit along a horizontal guide. A single pushing tool, set at an angle of 45 degrees, allows to effectively control the process of feeding microscrew blanks into thread rolling dies. This mechanism simplifies the adjustment of the machine and is ideal for thread rolling on micro screws with a large and thin head and a small shaft diameter.

The construction of the machine is designed from the beginning to reduce the requirements for the technical level of the machine operator - thread rolling equipment is equipped with various sensors and displays to help novice operators understand the cause of the malfunction, as well as quantitatively visualize the experience of master operators. For example, the amount of gap between thread rolling dies is digitized, making it easy to adjust the gap.

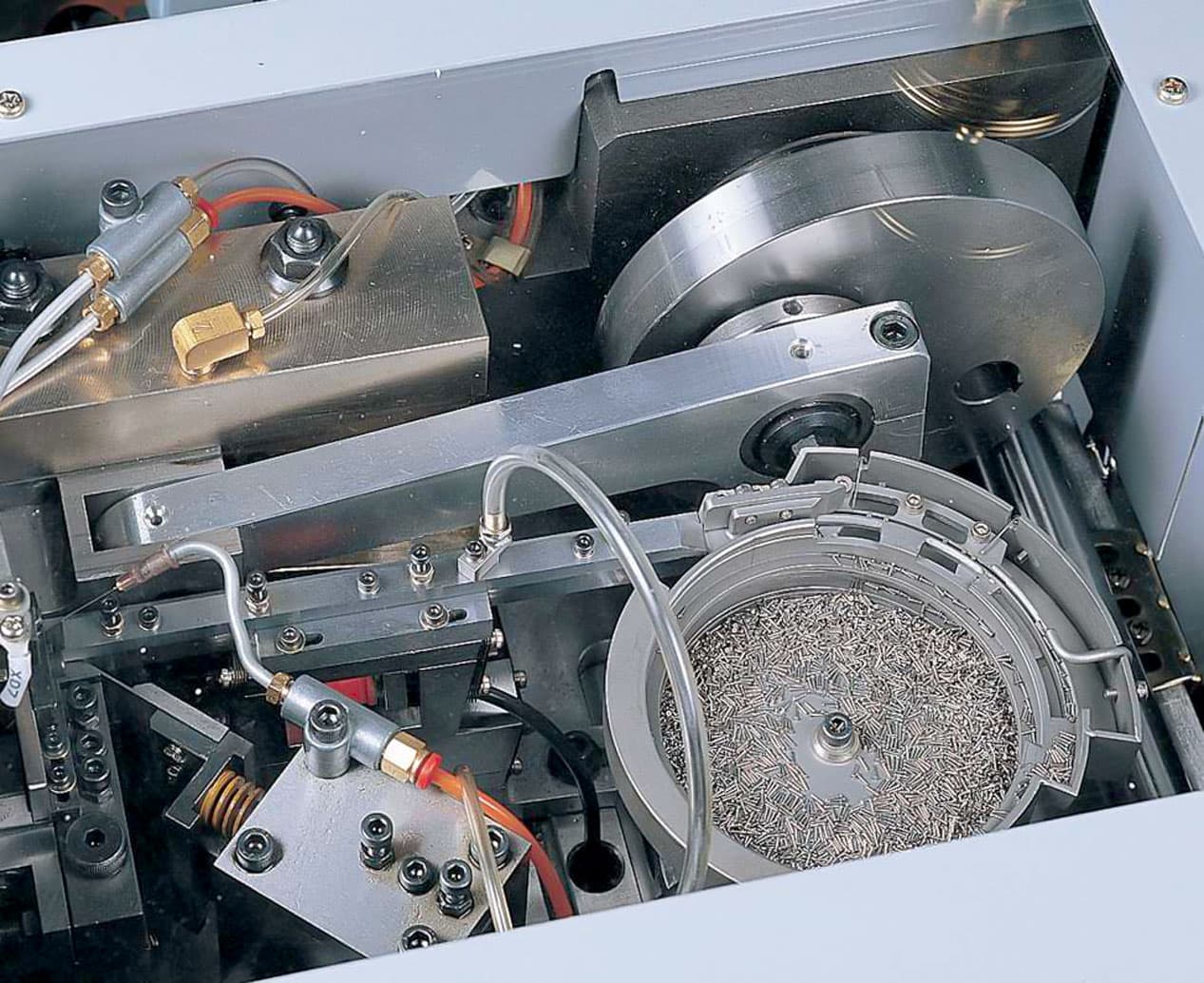

The flexible surface of the vibrating plate has a modular structure, auxiliary modules can be changed according to the shape of the workpieces.

The vibrating feed bowl can automatically adjust the number of blanks on the vibrating plate, which ensures a stable thread rolling process for standard and complex threads.

The thread rolling machine has a sealed casing that protects the internal working space of the machine from pollution by oil mist and dust. The casing increases the safety of personnel and reduces the noise of the equipment.

Features of the thread rolling machine

Flat Feeding

- Micro Feeding: stable orbital vibratory feed and linear vibratory feed instead of the previous free fall feed eliminates workpiece jamming.

- Efficient adjustment of the feed process due to the special design of a single pusher mounted at an angle of 45 degrees.

- The system for detecting defects in the thread rolling process monitors the situation of the floating head and thread defects.

- Adjustable vibrating disc design: The track spacing of the vibrating disc can be adjusted according to the product being produced.

- Information display: the amount of gap between thread rolling dies is displayed using a visual scale, providing the operator with the convenience of adjustment and reducing machine setup time.

- The one-way non-return oil circuit ensures stable oil pressure and improves the production stability of the machine.

- Basic safety configuration:

- dual-circuit emergency stop and power-off system;

- single-circuit (proximity) microswitch for safety door;

- DC working light;

- safety signal lamps. The color of the safety signal lights comply with the international color standard (green/ yellow/ red);

- numerical air oil pressure quantification.

- Optionally, the machine can be equipped with a rotary collector and a hopper.

| Model | Wire Diameter, mm | Shank Length, mm | Output capacity, pcs/min | Main Stroke, mm | Standard tool sizes, mm | Main motor power | Machine Sizes, L × W × H, cm | Net weight approx., kg | Feeding Type |

|---|---|---|---|---|---|---|---|---|---|

| RG-00L2 | M0.6 - M1.7 | 0.7 - 6 | 80 - 250 | 94 | 15 × 15 × 40 15 × 15 × 50 | 1 HP | 129 × 93 × 196 | 600 | Flat |

Video of the operation of the micro-thread rolling machine

Micro-screw thread rolling machine RG-00L3

| Model | Wire Diameter, mm | Shank Length, mm | Output capacity, pcs/min | Main Stroke, mm | Standard tool sizes, mm | Main motor power | Machine Sizes, L × W × H, cm | Net weight approx., kg | Feeding Type |

|---|---|---|---|---|---|---|---|---|---|

| RG-00L3 | M0.6 - M1.7 | 0.7 - 6 | 80 - 250 | 94 | 15 × 15 × 40 15 × 15 × 50 | 1 HP | 129 × 93 × 196 | 600 | Flat |

Micro screw thread rolling machine RG-05N2

Micro screw thread rolling machine RG-05N2 is designed for precision micro-thread rolling on screw products with outer diameter from M1.4 to M2.6 and length from 2 to 25 mm.

The thread rolling machine has a sealed casing that protects the internal working space of the machine from pollution by oil mist and dust. The casing increases the safety of personnel and reduces the noise of the equipment.

Slanted Feeding

- The vibratory feeder ensures a stable process of thread rolling of various profiles.

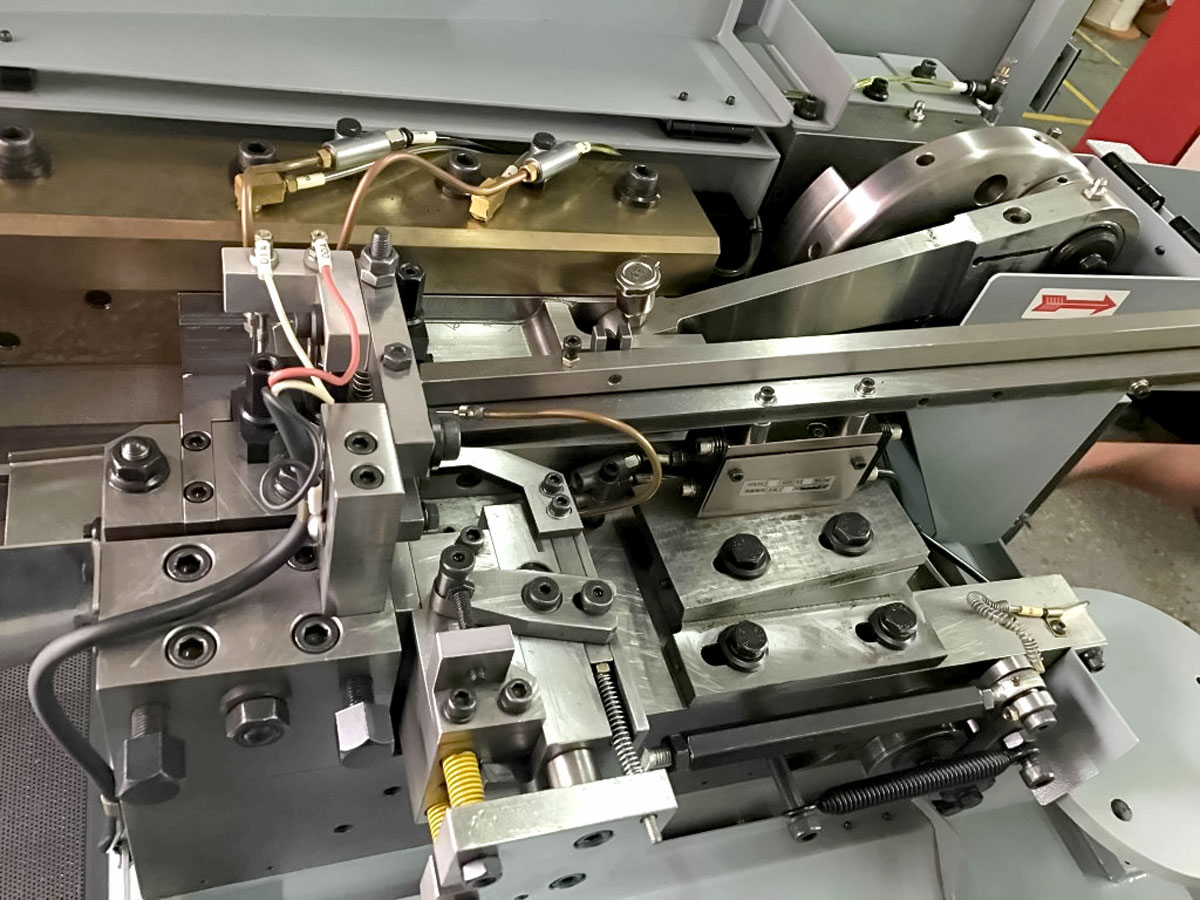

- Microscrew blanks are fed into the microthread rolling unit along an inclined guide. To increase the stability of feeding microscrew blanks into thread rolling dies, two screw blank pushers are used, installed at an angle of 45 degrees.

- The machine is ideal for thread rolling microscrews with large heads and small shank diameters.

- The one-way non-return oil circuit ensures stable oil pressure and improves the production stability of the machine.

- The optional product detection device can detect various thread rolling defects and separate the scrap and good parts without mixing them.

- Optionally, the machine can also be equipped with an HMI-interface and a rotary collector.

| Model | Wire Diameter, mm | Shank Length, mm | Output capacity, pcs/min | Main Stroke, mm | Standard tool sizes, mm | Main motor power | Machine Sizes, L × W × H, cm | Net weight approx., kg | Feeding Type |

|---|---|---|---|---|---|---|---|---|---|

| RG-05N2 | M1.4 - 2.6 мм | 2 - 25 | 80 - 250 | 136 / 146 | 19 × 25 × 51 19 × 25 × 64 | 2 HP | 155 × 115 × 197 | 600 | Slanted |

Video of the operation of the micro-thread rolling equipment

Micro-screw thread rolling machine RG-05N3

| Model | Wire Diameter, mm | Shank Length, mm | Output capacity, pcs/min | Main Stroke, mm | Standard tool sizes, mm | Main motor power | Machine Sizes, L × W × H, cm | Net weight approx., kg | Feeding Type |

|---|---|---|---|---|---|---|---|---|---|

| RG-05N3 | M1.4 - 2.6 мм | 2 - 25 | 80 - 250 | 136 / 146 | 19 × 25 × 51 19 × 25 × 64 | 2 HP | 155 × 115 × 197 | 600 | Slanted |