THREAD ROLLING MACHINES FOR THE FASTENERS INDUSTRY

THREAD ROLLING MACHINES FOR RODS, TUBES AND SPECIAL PARTS

Equipment thread- rolling on rods and special parts (hydraulic type)

EXAMPLE OF FINISHED PRODUCT

Features of equipment for rolling threads on rods and special parts:

- Weldment Frame.

- Volumetric coolant tank ensures its rapid cooling.

- The recirculation pump in the oil tank gearbox ensures optimal oil temperature.

- The transfer of torque to the profile roller through the driveline.

- Ability to handle large diameter blanks thanks to the maximum rolling force of 55 tons.

- Powerful spindle motor meets the requirements of production.

- The electrical part of the machine is made according to CE standard.

Specification of equipment for rolling threads on rods and special parts

| RG-530PS | RG-750P | RG-860P | |||||

|---|---|---|---|---|---|---|---|

| Thread Size | Min. outside diameter | Ø6 mm | 1/4 `` | Ø25 mm | 1`` | Ø25 mm | 1`` |

| Max. outside diameter | Ø80 mm | 3-1/8`` | Ø100 mm | 4`` | Ø125 mm | 5`` | |

| Max. thread pitch | 8 mm | 3 threads per inch | 10 mm | 2.5 threads per inch | 2.0P~12.0P | 2 turns per inch | |

| Operating shaft | Speed rolling | 59, 90, 136, 193 vol. / min. | 15, 23, 36, 52 vol. / min. | 15, 23, 36, 52 vol. / min. | |||

| Max. outside diameter | 200 mm | 240 mm | |||||

| Inner diameter | 70 mm | 80 mm | 3.25`` | ||||

| Max. width | 30-150 mm | 220 mm | |||||

| Max. rolling force | 35 tons | 55 tons | 100 tons | ||||

| Engine | Spindle | 20 PM | 25 PM | 40 PM | |||

| Hydraulic Pump | 5 PM | 10 PM | 15 PM | ||||

| Pumps for coolant | 1/8PM | 1/8 PM | ½ PM | ||||

| The pump speed switching box | 1/8 PM | 1/8 PM | 1/8 PM | ||||

| Net Weight | 3000 kg | 3300 kg | 5500 kg | ||||

| Gross weight | 3460 kg | 3860 kg | 6300 kg | ||||

| Footprint | 2000×1560 mm | 1650×2320 mm | 2520×2250×2400 mm | ||||

| Dimensions (L×W×H) | 2200×1720×1890 mm | 2520×1810×2070 mm | 2600×2400×2550 mm | ||||

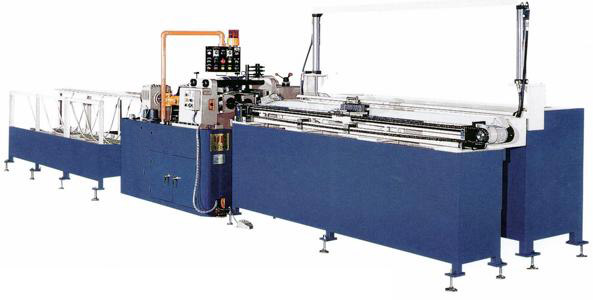

EQUIPMENT FOR ROLLING THREADS ON RODS (automatic blank feeding)

Equipment for rolling threads on rods designed for high speed and fully automatic threading of a wide spectrum, such as a single-cut thread, double-cut thread, triple-cut thread, UNF, etc. The machine has a high degree of stability. It is extremely powerful spindle motor provides an easy threading at high speed. Combining the functions of the thread rolling machine and rod feeder provides a strong reduction of the productive costs, increases productivity and competitive advantages. The design may be changed without notice to customers.

EXAMPLE OF FINISHED PRODUCT

EQUIPMENT FOR ROLLING THREADS ON RODS AND SPECIAL CAR PARTS (hydraulic type)

Features of equipment for rolling threads on rods and special car parts

- The ability to adjust the slide and the feed rate. The ability to adjust the force rolling, starting with 0.5 tons.

- Some models of thread-rolling cycles are controlled by a timer. This allows rolling threads on blanks with varying surface roughness by the usual adjustments.

- On request semiautomatic and automatic loading system are available operated by a foot pedal and electric rear focus.

- Especially widely used in the production of long pins, as well as the production of high-precision threading, slotted, worm gear, and parts of machinery.

- It combines the functionality of hydraulics with complete and simple control mode loading and feeding parts with a diameter of 16 mm.

EXAMPLE OF FINISHED PRODUCT

Specifications of equipment for rolling threads on rods and special car parts

| RG-310 | RG-420 | RG-530 | RG-530P | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Maximum blank dimensions | Inner diameter | 2-16 mm | 1/16``-5/8`` | 6-35 mm | ¼``-1 3/8`` | 6-65 mm | ¼``~2 ½`` | 6-80 mm | ¼``~3 1/8`` |

| Pitch | 0.4-2.0 P | 60-11 threads per inch | 0.75-4.0 P | 40-6 threads per inch | 0.75-6.0 P | 40-4 threads per inch | 0.75-8 P | 40-3 threads per inch | |

| Max. length | Loading and feeding modes are available | ||||||||

| Operating shaft | Speed rolling | 54 vol. / min. | 24, 38,52, 78 vol. / min. | 15, 23,36, 52 vol. / min. | |||||

| Max. outside diameter | 100 mm | 4`` | 150 mm | 180 mm | 200 mm | ||||

| Inner diameter | 50.5 mm | 2`` | 54 mm | 54 mm | 70 mm | ||||

| Max. width | 30-40 mm | 1-3/16``-1.9/ 16`` | 100 mm | 35-150 mm | 150 mm | ||||

| Max. distance between the centers of the spindle shaft | 120 mm | 5-1/8`` | 170 mm | 220 mm | 250 mm | ||||

| Min. distance between the centers of the spindle shaft | 90 mm | 3-1/2`` | 120 mm | 145 mm | |||||

| Max. rolling force | 4 tons | 17 tons | 35 tons | ||||||

| Performance, m. /min. | 1.2 | 1.5 | 2.7 | ||||||

| Engine 3 phase , alternating current | Spindle | 2 PM | 7.5 PM | 10 PM | 15 PM | ||||

| hydraulic Pump | 2 PM | 3 PM | 5 PM | ||||||

| Pumps for coolant | 1/8 PM | 1/8 PM | 1/8 PM | ||||||

| Machine housing | Footprint | 1400×940 mm | 1800×1350 mm | 2000×1560 mm | |||||

| Net Weight(approx.) | 480 kg | 1650 kg | 2700 kg | 3000 kg | |||||

| Gross weight (approx.) | 650 kg | 2000 kg | 3160 kg | 3460 kg | |||||

| Dimensions (L×W×H) | 1575×1030×910 mm | 2030×1490×1510 mm | 2200×1720×1890 mm | ||||||

EQUIPMENT for rolling threads on hardware and car parts (project for spec. order)

RG-588 Machine for rolling Slots

EXAMPLE OF FINISHED PRODUCT

Features of equipment for rolling threads on hardware and machine parts

- RG-588 machine has a more advanced design of feeding blanks system.

- Maximum unit: 1.0

- Maximum outer diameter: 30 mm

- Maximum length of rolling: 200 mm

EQUIPMENT for rolling threads on tubes RG-30A, RG-60A, RG-60AP (hydraulic type)

Example of finished product

Features of equipment for rolling threads on tubes:

- It combines functionality with hydraulic thread rolling mass of various kinds in the hollow profile of the coupling sleeves oil pipelines, electric fans shafts, parts for cars, bicycles, motorcycles, sewing machines, etc.

- Easy to manage, supports loading of parts with diameter up to 32 mm.

Specification of equipment for rolling threads on the pipe

| RG-30A | RG-60A | RG-60AP | |||||

|---|---|---|---|---|---|---|---|

| Maximum blank dimensions | Inner diameter | 8-30 mm | 5/16``- 1 1/8`` | 6-65 mm | ¼``~2 ½`` | 6-80 mm | ¼``~3 1/8`` |

| Pitch | 0.5-2.5 P | 40-11 threads per inch | 0.75-6.0 P | 40-4 threads per inch | 0.75-8 P | 40-3 threads per inch | |

| Max. length | Modes of loading and delivery throughfeed | ||||||

| Operating shaft | Speed rolling | 250 vol. / min. | 46, 65, 85, 120 vol. /min. | ||||

| Max. outside diameter | 80 mm | 3-1/8`` | 140 mm | ||||

| Inner diameter | 25.4 mm | 1`` | 40 mm | ||||

| Max. width | 20, 30, 40 mm | 1-5/8`` | 50 mm | ||||

| Max. distance between the centers of the spindle shaft | 130 mm | 5-1/8`` | 210 mm | ||||

| Min. the distance between the centers of the spindle shaft | 50 mm | 2`` | 75 mm | ||||

| Performance, pcs. /min. | 9-35 | 9-35 | Cut along the lines | ||||

| Engine 3 phase , alternating current | Spindle | 2 PM | 5 PM | 7.5 PM | |||

| hydraulic Pump | 2 PM | 3 PM (5PM) OPT | |||||

| Pumps for coolant | 1/8 PM | 1/8 PM | |||||

| Machine housing | Footprint | 1120×930 mm | 1360×1250 mm | ||||

| Net Weight (approx.) | 550 kg | 1150 kg | 1200 kg | ||||

| Gross weight (approx.) | 720 kg | 1380 kg | 1400 kg | ||||

| Dimensions (L×W×H) | 1320×1130×1570 mm | 1560×1450×1650 mm | |||||

EQUIPMENT FOR ROLLING THREADS ON SPECIAL PARTS RG-3T, RG-20, RG-30

Equipment for rolling threads on special details combines feed eccentric cam, simple design and ease of use in the manufacture of small screws for sewing machines, bicycles, cars, motorcycles, hardware, tools, and precision equipment.

The combination of the speed reduction mechanism and an eccentric rotation thread rolling rollers provides more accurate and convenient production of a wide range of threaded parts. This equipment is completed with a lubrication system for longer life guides.

EXAMPLE OF FINISHED PRODUCT

Specification of equipment for rolling threads on special items

| RG-3T | RG-20 | RG-30 | |||||

|---|---|---|---|---|---|---|---|

| Maximum blank dimensions | Inner diameter | 0.8-12.5 mm | 1/32``-1/2`` | 5-22 mm | 3/16``-7/8`` | 5-40 mm | 5/16``-1.9/16`` |

| Pitch | 0.4-1.5 P | 60-16 threads per inch | 0.75-2.5 P | 40-9 threads per inch | 0.75-3.0P | 40-8 threads per inch | |

| Max. length | 38 mm | 1-1/2`` | 48 mm | 1-7/8`` | 150 mm | 6`` | |

| Operating shaft | Speed rolling | 40 vol. / min. | 40 vol. / min. | 40 vol. / min. | |||

| Max. outside diameter | 100 mm | 4`` | 120 mm | 4-3/4`` | 150 mm | 6`` | |

| Inner diameter | 50.5 mm | 2`` | 40 mm | 1-9/16`` | 54 mm | 2-1/8`` | |

| Max. width | 40 mm | 1-9/16`` | 50 mm | 2`` | 150 mm | 6`` | |

| Max. distance between the centers of the spindle shaft | 130 mm | 5-1/8`` | 140 mm | 5-1/2`` | 187 mm | 7-3/8`` | |

| Min. the distance between the centers of the spindle shaft | 90 mm | 3-1/2`` | 100 mm | 4`` | 140 mm | 5-1/2`` | |

| Performance, m. /min. | 20-40 | 9-30 | 7-20 | ||||

| Engine 3 phase , alternating current | Spindle | 1 PM | 3PM | 7-1/2 PM | |||

| Pumps for coolant | 1/8 PM | 1/8 PM | 1/8 PM | ||||

| Machine parameters | Footprint | 800×600 mm | 1090×740 mm | 1220×810 mm | |||

| Net weight (approx.) | 300 kg | 970 kg | 1300 kg | ||||

| Gross weight (approx.) | 395 kg | 1130 kg | 1480 kg | ||||

| Dimensions(L×W×H) | 940×700×910 mm | 1240×850×1220 mm | 1365×925×1295 mm | ||||

EQUIPMENT for rolling threads on hardware and car parts RG-800/1225

- Machine for rolling slots on precision parts for automobiles, motorcycles, agricultural machinery, filters, pneumatic, hydraulic, and other tools.

- The equipment is characterized by high precision slots rolling, forming jagged shapes, ideal for serial processing of products as well as for the treatment of non-standard products.

- Equipment for rolling slots is capable of forming slots, serrations, oil grooves, making incisions, to roll a thread of articles during continuous feeding separately. Processing of one product takes from 3 to 7 seconds.

- The final products have ideal solid surface without burrs.

The standard accessory kit of equipment for Slots rolling :

- Protective device of the machine.

- The installation mechanism for parts of the machine.

- Coolant feeding system.

- Cooling system.

- Electric control.

- Tooling.

- Operation and maintenance of the machine.

Optional accessories:

- A set of dies for forming threads and slots.

- Automatic loading.

- Computing Centre.

- Acceptance of the Customer.

Example of finished product

Specification of equipment for rolling Slots

RG-800 | RG-1225 | |

|---|---|---|

| minimum diameter, mm | 16 (0.63") | 16 (0.63") |

| maximum diameter of the slot, mm | 40 (1.57") | 50 (1.97") |

| maximum length of the slot, mm | 110 (4.33") | 110 (4.33") |

| minimum length, mm | 100 (3.94") | 100 (3.94") |

| maximum length, mm | 1000 (39.37") | 1200 (47.24") |

| Maximum toothing Module | 1.25 | 1.5 |

| Standard length of dies for forming slots | 640 mm(24") | 915 mm(36") (an additional 1220 mm, 48") |

| Standard length of dies for forming threads | 360 mm(14.17") | 360 mm(14.17") |

| The hydraulic motor | 40 hp (6P) | 50 hp (6P) |

| Pump cooling system | 5 hp | 5 hp |

| Programmable Logic Controller | Mitsubishi | Mitsubishi |

| The size of the equipment (L×W×H mm) | 2700×4200×2100 | 3700×4200×2100 |

| The size of the equipment V упакоVки (L×W×H mm) | 4000×5000×3000 | 5000×5000×3000 |

| Net Weight, kg | 12.000 kg | 15.000 kg |

| Weight, kg | 12.500 kg | 15.600 kg |