COLD FORGING PRESSES FOR WASHER PRODUCTION

SERVO COLD FORGING PRESS MACHINE FOR STAMPING WHEEL NUTS AND WASHERS FROM WIRE AND ROD

The RCF series cold forging press is designed for cold stamping of wheel nuts and washers in sizes M16, M18, M20, M22, M24, M27 from wire and rod. The equipment set consists of a 3-position cold forging press with a servo drive, a press for flattening the workpiece and a cutting machine for cutting the workpiece from wire, interconnected by an automatic workpiece transfer system.

| Model Name | RCF-330 | RCF-530 | RCF-345 | RCF-545 | RCF-363 | RCF-563 | RCF-380 | RCF-580 | RCF-3100 | RCF-5100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | KN | 3000 | 4500 | 6300 | 8000 | 10000 | |||||

| Rated tonnage point (above B.D.C.) | mm | 7 | 8 | 10 | |||||||

| Stroke | mm | 160 | 180 | 220 | 250 | ||||||

| Speed (number of strokes per minute) | SPM | 45 | 40 | 35 | 30 | ||||||

| Distance between the die plate and the slider in its lower position with the upper adjustment position | mm | 500 | 550 | 600 | 700 | ||||||

| Slider Adjustment | mm | 25 | |||||||||

| Slider Area | mm | 800 × 700 | 1100 × 700 | 850 × 750 | 1150 × 750 | 900 × 800 | 1300 × 800 | 1000 × 850 | 1400 × 850 | 1000 × 850 | 1450 × 850 |

| Bolster Area | mm | 900 × 830 | 1200 × 830 | 950 × 870 | 1250 × 870 | 1000 × 950 | 1400 × 950 | 1100 × 1050 | 1500 × 950 | 1100 × 1050 | 1550 × 1050 |

| Dies Pitch | mm | 160 | 180 | 220 | 240 | 260 | |||||

| Punch Hole | mm | 100 | 120 | 140 | 150 | ||||||

| Main Die Hole | mm | 130 | 150 | 180 | 200 | 220 | |||||

| Lower Knockout Stroke | mm | 50 | 60 | 80 | 100 | ||||||

| Upper Knockout Stroke | mm | 35 | 40 | 45 | 50 | ||||||

| Bolster Thikness | mm | 150 | 180 | 150 | 200 | 230 | 200 | 250 | 200 | 250 | |

| Bolster Surface Height | mm | 900 | 1000 | 1150 | 1100 | 1250 | 1200 | 1400 | 1200 | 1400 | |

| Main Motor Power | kW | 75 | 95 | 132 | 150 | 185 | 175 | 210 | |||

| Required Air Pressure | kg/sm2 | 5 | |||||||||

| Model Name | RSD-200 | RSD-300 | RSD-400 | RSD-600 | |

|---|---|---|---|---|---|

| Capacity | KN | 2000 | 3000 | 4000 | 6000 |

| Rated tonnage point (above B.D.C.) | mm | 7 | 8 | 10 | |

| Stroke | mm | 150 | 180 | 200 | 220 |

| Speed (number of strokes per minute) | SPM | 50 | 45 | 40 | 35 |

| Slider Adjustment | mm | 12 | 15 | ||

| Maximum Cutting Diameter | mm | 20-30 | 20-36 | 25-42 | 30-50 |

| Cutting Lenght | mm | 15-35 | 15-40 | 20-40 | 25-50 |

| Minimum Product Thikness | mm | 6 | 8 | 10 | |

| Maximum Product Diameter | mm | 42 | 52 | 63 | 75 |

| Main Motor Power | kW | 20 | 30 | 45 | 55 |

| Required Air Pressure | kg/sm2 | 5 | |||

| Model Name | RTF-150 | RTF-200 | RTF-250 | |

|---|---|---|---|---|

| Feed Stroke | mm | 120-180 | 150-220 | 200-280 |

| Clamp Stroke (one side) | mm | 20-40 | 30-70 | 30-80 |

| Clamp Arm inner Width | mm | 130-160 | 180-240 | 200-250 |

| Clamp maximum Length | mm | 800 | 1200 | 1400 |

| Size of Feed Line | mm | 35 × 35 | 60 × 50 | 70 × 60 |

Design Features of a Press with a Servo Drive

The equipment is a CNC mechanical press designed for the production of wheel nuts and washers through cold forging from wire and rod.

Its operation principle is based on transforming the rotational motion of the drive into the reciprocating motion of the slider.

The working part of the cold forging press is a stamp consisting of two halves: the upper movable (punch) and the lower fixed (die). The die is attached to the press table, while the punch is affixed to the press slide.

The press machine includes an automatic mechanism for feeding metal into the working area, a calibration device for straightening the rod workpiece, and a conveyor for removing metal shavings from beneath the working area.

The main engine of the press machine is equipped with oil cooling, and the cold heading press features a centralized lubricant supply system.

For cold forging washers and nuts, the press is equipped with a Kingservo servo drive from Taiwan. In comparison with traditional knuckle joint cold forging presses, this design decelerates the ram at the bottom dead center, enhancing forming accuracy. The contact speed of the stamp is low, extending the service life of both the stamps and the press, and reducing noise at the point of contact. The servo drive with negative feedback control ensures precise control of motion parameters, with key characteristics including motor dynamics, motion uniformity, and energy efficiency. This servo drive design is highly optimal for forging operations, cutting thick sheets, and cold forming.

The operator controls the press through a touch screen, adjusting all production parameters, including productivity, die equipment height, feed length, and others.

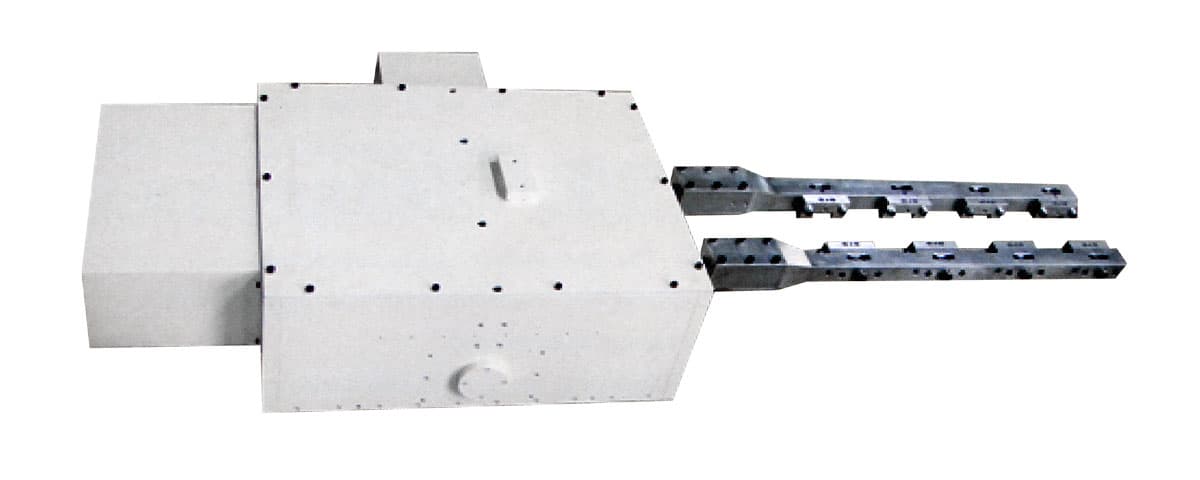

The press body, designed like a box, offers excellent rigidity and improved bottom dead center accuracy. Holes on the sides facilitate the convenient installation of additional equipment for automation and protection, according to customer requirements.

The cold forging press drive is completely concealed inside the housing. The press ram is driven by a servo drive, gears, and an eccentric shaft, connected by toggle joints.

A safety brake is incorporated. If no operation occurs within 30 seconds after the main motor starts operating, the safety brake automatically cuts off the power supply to the main motor, stopping the mechanism instantly. The safety brake design employs dry friction pads.

The press's safety system adheres to the highest press machine safety standards, ensuring worker comfort and safety. It includes photoelectric sensors that automatically shut off the equipment when foreign objects enter the work area. Additionally, the press safety system features emergency stop devices, motor overload protection, prevention of excessively low rotation speeds, and error monitoring.

A typical set of equipment for the production of truck wheel nuts

- 3-position automatic servo-driven press for cold forging of products.

- Continuous Die set with programmable progressive step and quick change system.

- Mechanism with servo drive for automatic workpieces transfer.

- Cutting and flattening press machine.

- Straightening and unwinding device for wire..

Technological process for manufacturing a wheel washer by stamping from wire or rod

The coil of wire is installed on the unwinder. The wire is unwinded and fed to the wire straightening device. The feed rate is controlled by the inverter. The wire straightening device guides the wire with steel rolls in the vertical and horizontal plane. Next, the feed mechanism directs the end of the wire to a cutting machine to cut the wire to length and flatten it using a hammer.

After this, the flattened workpiece is moved using a transport mechanism or conveyor into the vibrating hopper of a 3-position cold forging press.

From the vibrating hopper, the workpiece is moved along a guide to the cold forging zone. An automatic workpiece transfer mechanism (grab transfer) with a servo drive alternately moves the workpiece to forging positions 1, 2 and 3.

In the first forging position, preliminary deformation of the wheel nut (washer) is performed. In the second position, the piercing punch forms the hole for the future product. In the third position, the product becomes marketable. Then the products are unloaded into factory containers.

STAMPING OF PRODUCTS FROM WIRE AND ROD - 100% WASTE-FREE PRODUCTION

ECONOMICAL USE OF RAW MATERIALS

100% waste-free production

metal scrap and shavings 50%

Possibility of re-adjusting cold forging presses for upsetting products from rods (coils of wire) and from steel sheets

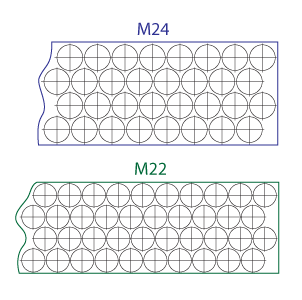

Cold forging presses are ideal for upsetting washers and various flat products. A special feature of this equipment is the ability to plant flat-shaped products from metal rods, as well as from sheet metal.

The dies are made of high quality metal SKD-11 and S45C.

The possibility of lateral movement (left/right) of the workpiece feed mechanism allows you to punch holes of up to five pieces across the width of the strip. This allows for the most efficient use of the workpiece metal and minimizes production waste when stamping washers from sheet steel.

Photo gallery

Cold forging of a washer made of wires

Cold stamping of metal plates for fastening barrier-type road fences

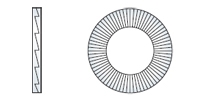

TYPES OF MANUFACTURED PRODUCTS

High-strength washers

Washer, high strength

Washer, high strength

Washer, high strength

Small diameter fasteners (micro fasteners)

Spring washer (Grover), a small-diameter steel

Washer, flat, small

diameter steel

Reinforced washer (body), small diameter steel

Lock washer with external teeth, a small-diameter steel

Stainless steel washers

Washer, flat, stainless steel

Spring washer (Grover)

Reinforced washer (body)

Lock washer with external teeth, stainless

Retaining rings

Retaining ring for shaft

Lock ring for holes

Washers are not included in other sections

Flat washer GOST 11371-81 (DIN 125), GOST 6958-78 (DIN 9021), reinforced

Spring washer (Grover).

Normal, heavy, light

Washer

Lock quick

EPDM with

rubber shim

Lock washer with

notches (spring)

Lock

washers

Spring

Dished

Split

Washer

Lock crow

Washer

Lock

Washer