COLD FORMING EQUIPMENT FOR NAIL PRODUCTION

Complete line for cold heading of nails, forming thread on nails and assembly of finished nails into coil for pneumatic nailing guns

Coiled Nails designed to improve fastening efficiency

Drum nails for a pneumatic gun are used in industrial workshop work when assembling various wooden containers. Coiled roofing nails are used in construction work to fasten the roofing of buildings. Also, there are special roofing nails, which differ in a different diameter of the head and the steel rod itself. Rack nails with a round head, welded on a plastic tape with an angle of 21 degrees DIN EN10230 PE-Strips.

Scope - various wooden frames, fences, barriers, cable drums, pallets, wooden housing construction. Rack nails with a D-shaped head glued on a paper tape with a gluing angle of 34 degrees. The main application is the work with nailing tools in the production of frame structures and wooden housing construction.

Taiwan Metiz Alliance offers a turnkey complete line for cold heading nails, threading and assembling finished nails into a drum cage for pneumatic nailing guns with a capacity of up to 2500 pcs/min.

The composition of the line for the production of drum nails (turnkey)

The line consists of 3 main components:

- Equipment for cold heading of nails.

- Thread rolling equipment for the formation of threads on nails (for example, in the case of the production of screw nails or ring shank coil nails).

- Equipment for welding nails with steel wire into a drum holder for a nailer (high-speed collator machine).

Equipment features

- The equipment can be supplied either separately, by components or on a turnkey basis (3 in 1).

- An important feature of the equipment is its high productivity up to 2500 pcs/min.

- The turnkey production time for a line of equipment is 3-4 months.

High speed cold heading equipment for nails (component 1)

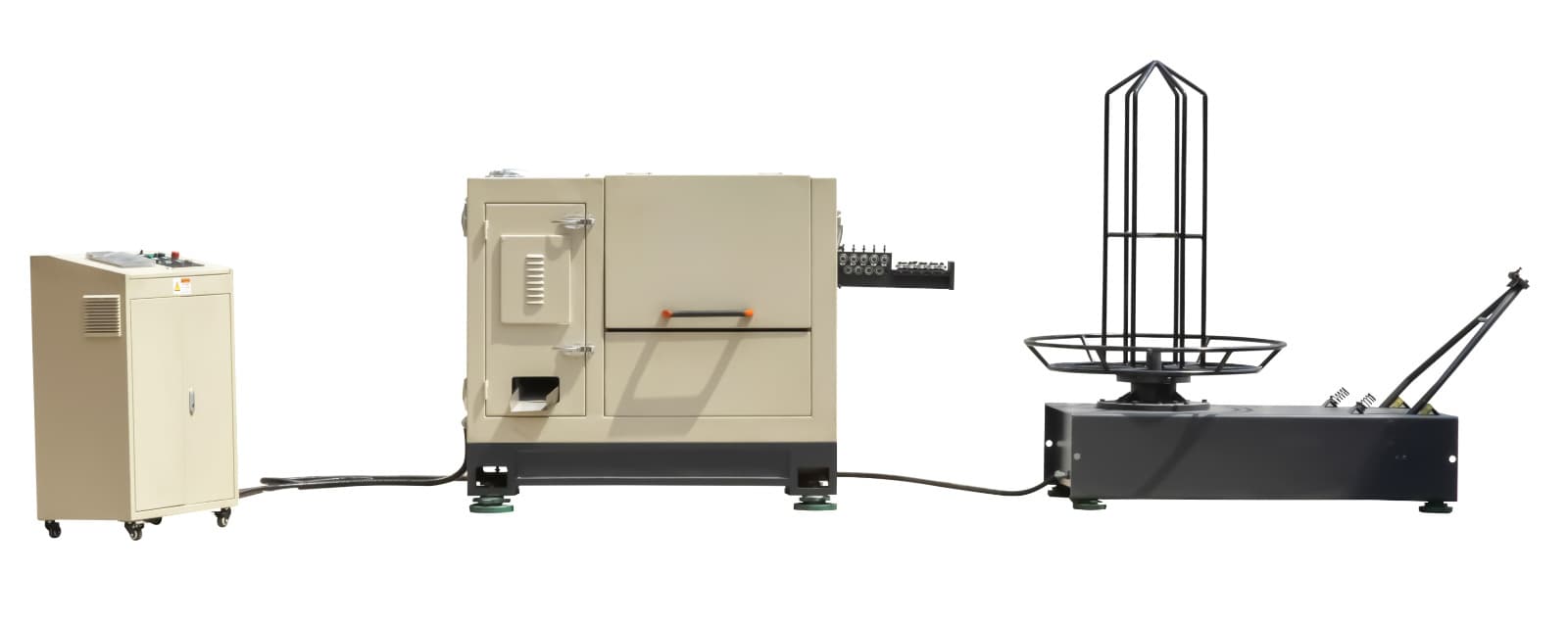

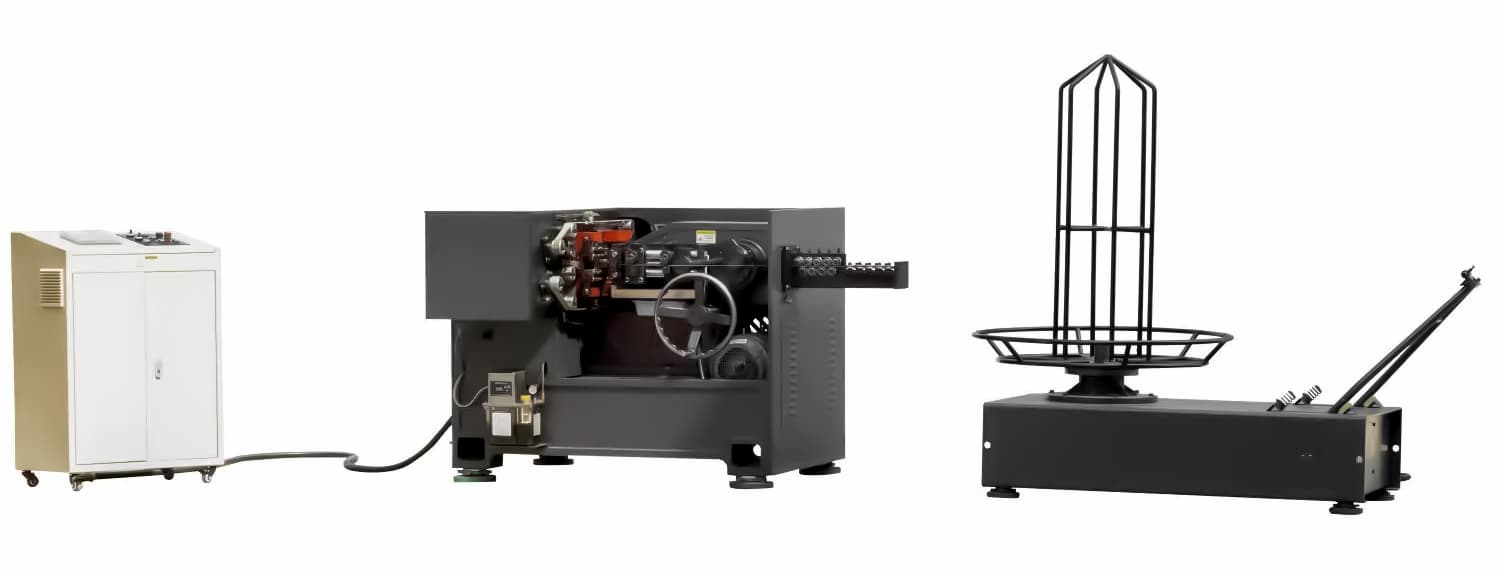

RG-5G High Speed Nail Machine With Anti-Noise Cover

| Nailing machine model | RG-5G |

|---|---|

| Nail Diameter | 2.0 - 2.5 mm |

| Nail Length | 32 - 50 mm |

| Performance | up to 800 pcs/min |

| Power consumption | 7 kW |

| Supply voltage | 3 phase / AC 380V / 50 ~ 60Hz |

| Dimensions of equipment, L × W × H | 1350 × 900 × 1260 mm |

| Weight | 2500 kg |

| Wire grade | SAE1008-1010 |

The set of equipment includes:

- wire pay-off (max 1 ton);

- electronic control cabinet including PLC;

- 1 set of forming tool;

- case with anti-noise cover;

- mounting kit;

- operating instructions in English.

Operation video of RG-5G series high speed nailer

RG-9G High Speed Nail Machine With Anti-Noise Cover

| Nailing machine model | RG-9G | RG-9G-XZ |

|---|---|---|

| Nail Head | round | D-head |

| Nail Diameter | 2.0 - 3.5 mm | |

| Nail Length | 45 - 90 mm | |

| Performance | up to 760 pcs/min | |

| Power consumption | 7 kW | |

| Supply voltage | 3 phase / AC 380V / 50 ~ 60Hz | |

| Dimensions of equipment, L × W × H | 1400 × 1200 × 1100 mm | |

| Weight | 2800 kg | |

| Wire grade | SAE1008-1010 | |

The set of equipment includes:

- wire pay-off (max 1 ton);

- electronic control cabinet including PLC;

- 1 set of forming tool;

- case with anti-noise cover;

- mounting kit;

- operating instructions in English.

Operation video of RG-9G series high speed nailer

RG-13G High Speed Nail Machine Without Anti-Noise Cover

| Nailing machine model | RG-13G |

|---|---|

| Nail Diameter | 2.5 - 4.5 mm |

| Nail Length | 50 - 130 mm |

| Performance | up to 600 pcs/min |

| Power consumption | 14 kW |

| Supply voltage | 3 phase / AC 380V / 50 ~ 60Hz |

| Dimensions of equipment, L × W × H | 1500 × 1300 × 1300 mm |

| Weight | 4000 kg |

| Wire grade | SAE1008-1055 |

The set of equipment includes:

- wire pay-off (max for 2 tons wires);

- electronic control cabinet including PLC;

- 1 set of forming tool;

- case with safety cover;

- mounting kit;

- operating instructions in English.

RG-15G High Speed Nail Machine with Anti-Noise Cover

| Nailing machine model | RG-15G |

|---|---|

| Nail Diameter | 2.5 - 4.5 mm |

| Nail Length | 70 - 150 mm |

| Performance | up to 550 pcs/min |

| Power consumption | 14 kW |

| Supply voltage | 3 phase / AC 380V / 50 ~ 60Hz |

| Dimensions of equipment, L × W × H | 1650 × 1200 × 1300 mm |

| Weight | 4500 kg |

| Wire grade | SAE1008-1010 |

The set of equipment includes:

- wire pay-off (max for 2 tons wires);

- electronic control cabinet including PLC;

- 1 set of forming tool;

- case with safety cover;

- mounting kit;

- operating instructions in English.

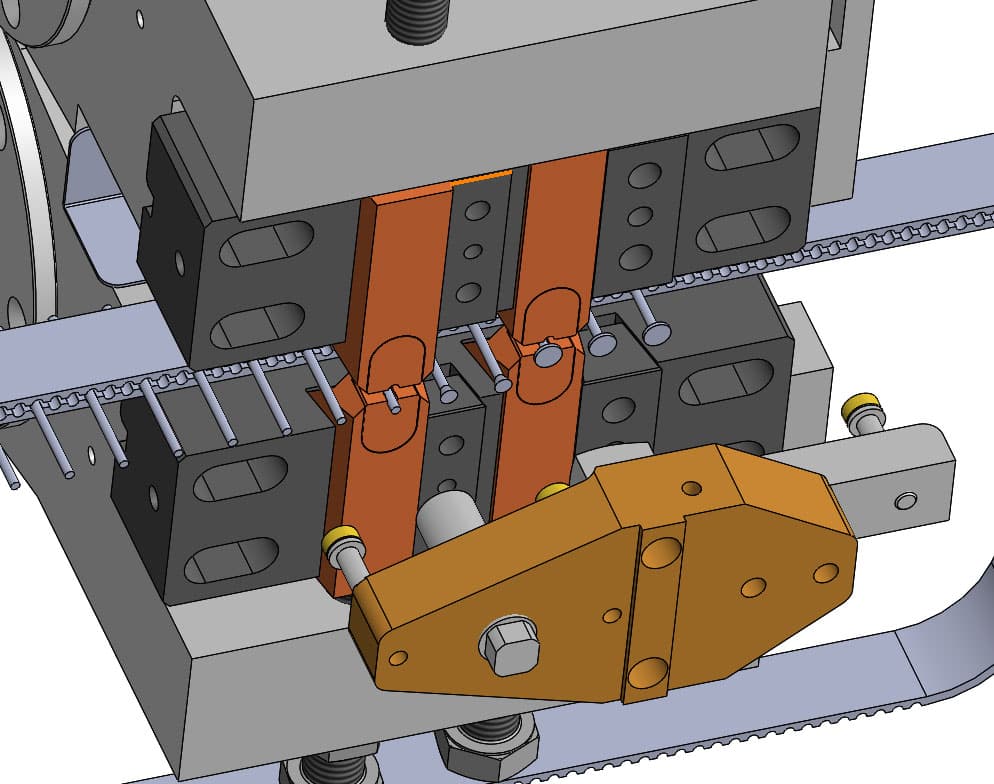

Design features of Nail Machines

The precision wire feeder makes it easy to control the length of the nail. The error in the length of each nail is controlled within ±0.3 mm. The unique combination of wire feed and return after cutting allows complete separation of the nail from the nail shank for maximum quality.

The cut-off knife holder has a special design (pendulum type), characterized by a shorter stroke and low mechanical wear of the cutting tool. High cutting accuracy and protection of the cutting tool - the knives work without touching each other. The service life of one set of knives reaches up to 10 million cuts. The design allows for easy adjustment of the position of the knives.

Double Upset Mode - Special design with double die and double punch. The recessed clamping jaws do not need to be changed frequently and allow us to stamp beautiful, impact-free, round nail heads of uniform thickness and perfectly centered. Also this design ensures that nail cap will be perfectly punched even nail rod is bad cutting.

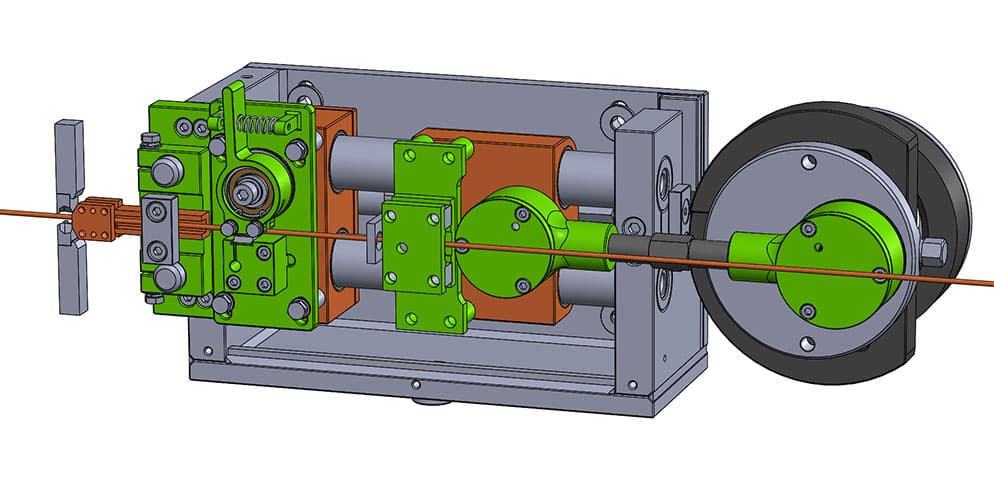

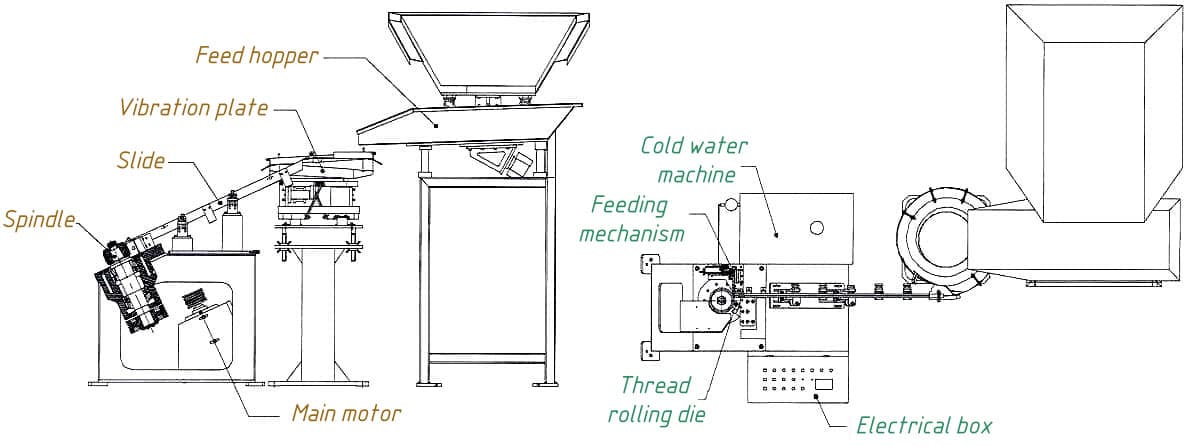

Automatic High Speed Thread Rolling Machine for Ring Shank Nails and Screw Shank Nails RS-B6-1 (component 2)

This machine is used for making thread on the nail to increase the tightness

Thread Rolling Machine Specifications

| Performance | 2400 pcs/min |

|---|---|

| Nail Diameter | 2.1 mm - 4.1 mm |

| Nail Length | 30 - 90 mm |

| Thread Length | Max. 80 mm |

| Engine power | 5.5 kW |

| Vibrating hopper capacity | 5 kg |

| Dimensions of equipment, L × W × H | 1400 × 1400 × 1600 mm |

| Net weight | 1300 kg |

The set of equipment includes:

- Nail Feed Hopper;

- Control Panel;

- Thread Rolling Dies (one set);

- Mounting Kit;

- Instruction manual in English.

Thread Rolling Equipment Sketch

Video of the thread rolling machine for ring shank nails and screw shank nails

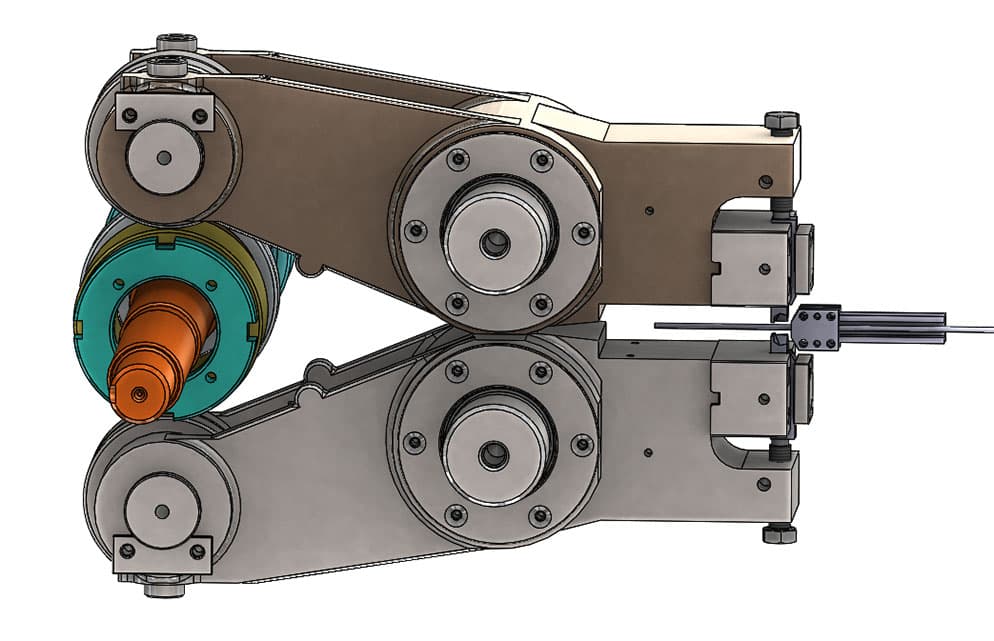

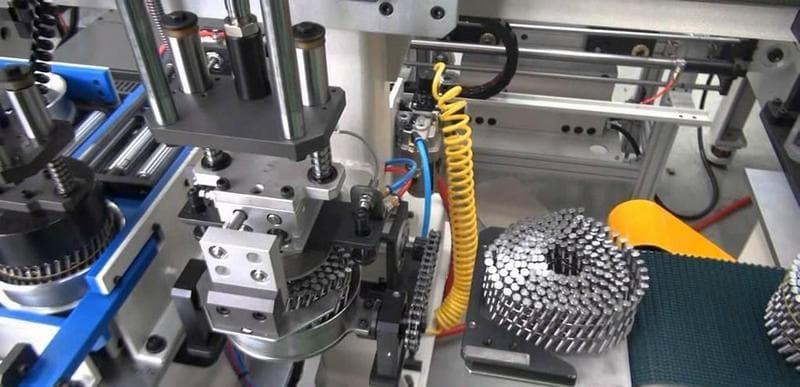

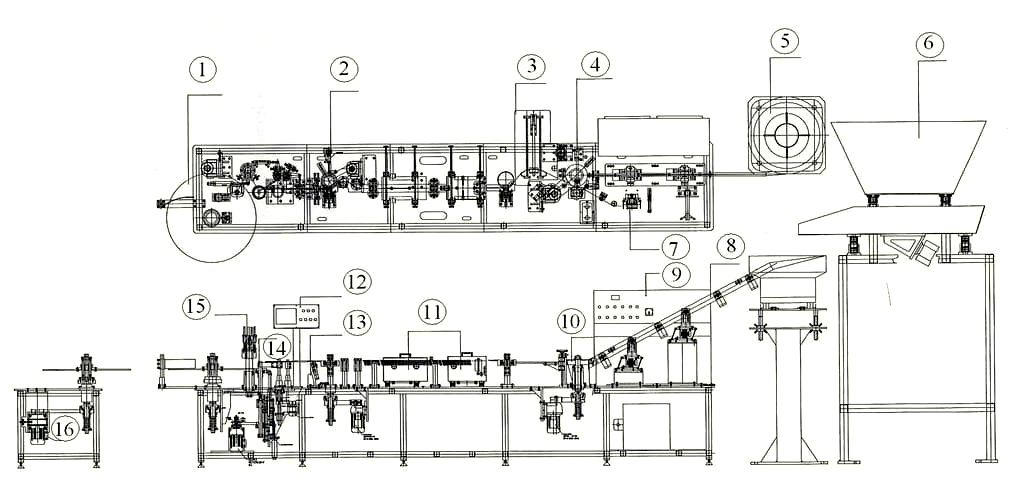

Wire coil nail collator for welding nails on wire with a capacity of 2500 pcs/min (component 3)

Special collator machine that bundles nails with steel wire in drum clips is used in production of Wire Coil Nails for pneumatic nailing hammers. Ring shank nails, screw shank nails or special/smooth shank nails are used as blanks for the collator machine. The collator machine has a built-in varnishing and painting system.

Nail Collator Sketch

Model RG25

- Receiving mechanism

- Switching mechanism

- Accumulation plate

- Pressing mechanism

- Vibrating bowl

- Hopper

- Wire feed wheel

- The guide

- Electric control cabinet

- Wheel of accumulation

- Coating cabinet

- Control panel

- Cutting mechanism

- Coil twisting mechanism

- Disk of curling

- Motor

RG25 Specifications

- Productive capacity: 2500 pcs/min

- Nail Diameter: 2.10 ~ 3.70 mm

- Nail Length: 25 ~ 100 mm

- Collation angle: 0 and 16 degrees

- Electrical Power Supply: 380V, 3 Phase / 220V / 50 ~ 60Hz

- Overall Dimensions (W × L × H): 1500 × 5000 × 1800 mm

- Nail number: 200 ~ 400 pcs.

More detailed information about collator machines for the production of bobbin nails (drum nails) is published on the page.

We also supply equipment for the production of paper strip nails.

Finished product - nail gun nails in coil pack bundle

Nails for a pneumatic gun, nailer are a set of several dozen metal nails, connected in special bobbins or cassettes for placing in a gun magazine. Serve for fixing parts or materials to the base. Provides a strong connection between the elements. Various bundles of nails in a cassette are used. Wiring, for example, is common when joining smooth, screw and ring nails into a drum cage. And rack nails are tied with a tape of plastic or paper. For pallets (they are also wooden pallets), drum nails up to 400 pieces in one reel are used. For stronger fastening, ring knurled nails are used, and screw knurled nails enter frozen wood much more easily. For work with metal or concrete, dowel-nails in a plastic clip are used. And for those parts in which the attachment point is subsequently processed with a milling cutter on a machine, nails made of aluminum are used.

Pneumatic nailer

A pneumatic nail gun (pneumatic nailer) is used at all stages of construction and work on wood and concrete: for example, from the installation of load-bearing structures and battens, to the installation of the roof and fixing the platbands. The tool is also used in apartment renovation, installing doors and window sills, assembling furniture, making pallets, boxes and other products.