PACKAGING EQUIPMENT FOR FASTENERS, METAL HARDWARE AND PARTS

GENERAL INFORMATION ABOUT PACKING TECHNOLOGY TIPPING AND LOADING EQUIPMENT FORMATION OF CARDBOARD CONTAINERS FILLING AND PACKAGING OF FASTENERS BY WEIGHT COUNTING PACKING MACHINES FOR FASTENERS LABELING EQUIPMENT PALLETIZERS AND WRAPPERS CONVEYORS FOR PACKING EQUIPMENT TURN KEY PACKAGING SOLUTION AUTOMATED WAREHOUSING EQUIPMENT WIRE WINDING AND PACKING EQUIPMENT NAIL PACKING SYSTEM

TURNKEY PROJECTS FOR FASTENERS PACKAGING

Completed projects - packaging lines for nuts and bolts

Appearance of packaging equipment and technical description of the packaging equipment operation process

Formation of a sheet of cardboard boxes automatically. Entering data size of the package by using the touch screen.

Capture of the packaging container by means of compressed air carried by the suction cups. After that, the lower base of the box is fixed by means of brackets air gun.

The finished package is moving on the conveyor belt to the loader of fasteners.

Loading and subsequent packaging is performed independently for fixing bolts and nuts, separately from each other.

Hopper using a vibration motor delivers fasteners on countable-packaging machine. Optionally the customer can purchase additional lifting conveyor for feeding fasteners into the hopper.

Feed fixture on countably packaging mechanism is carried out automatically on the conveyor hopper.

Vibration motor provides gradual process of feeding fasteners from the hopper by conveyor loader to countable-fill mechanism.

Loading fixture in boxes is made countable Filling mechanism according to the set parameters on the touch screen (by weight of the piece).

When the holder is loaded, folding and sealing cap made automatically stapled by air gun.

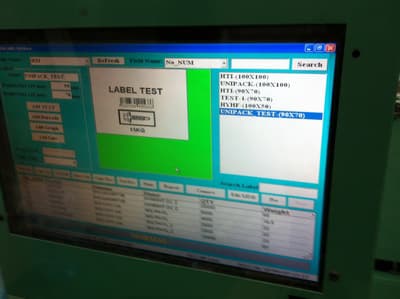

The design of the label can be optionally configured via a normal PC.

You can manually put your company's logo, name, address, type of product, size, steel grade, quantity, weight and other parameters.

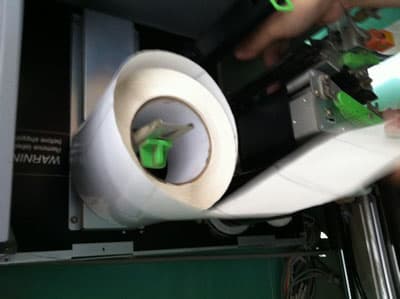

Equipment for applying labels automatically and sequentially applies the label on the lateral surface of the package. Optionally, you can adjust the location of the labels.

After sealing and labeling of the finished package conveyer moves into a zone of palletizing.

Laying on pallets automatically. The number of levels of containers on a pallet previously is programmed manually using a PC.

There are automatic feeding pallet stacker zone, while the loading of pallets of equipment carried by hand or with help of the car.

With pallet chain mechanism smoothly moves into the zone of the package stacker (zone palletizing).

On one pallet up to 5-6 levels of packaging is held.

Stacker container per pallet generates levels automatically.

After the pallet is stacked, the conveyor forwards it to the wrapping machinery. The package is wrapped by polyethylene film with the rotary conveyor.

Ready-packed products is consistently moving on roller conveyor in the unloading zone.