PACKAGING EQUIPMENT FOR FASTENERS, METAL HARDWARE AND PARTS

AUTOMATIC WAREHOUSING EQUIPMENT

Automatic storage systems are designed for buffer storage and high-speed transport of cardboard boxes, pallets and small plastic or metal containers. The presence of an automated warehouse allows you to reduce the time for searching and moving finished products, as well as completely eliminates the possibility of errors when placing an order. An automated warehouse, controlled by a computer, allows to reduce the consumption of labor resources and, allows you to reduce production costs.

Based on its many advantages, the automated warehousing and storage system is widely used internationally. Automation is playing an increasingly central role in the control system.

Intelligent control allows the automatic stacker crane to calculate the required travel path and move simultaneously on the vertical and horizontal axis. It also calculates the speed of movement and the length of the path of movement.

Stacker cranes are monitored by industrial controllers and every stacker crane operation is monitored with safety and positioning sensors to ensure maximum system reliability.

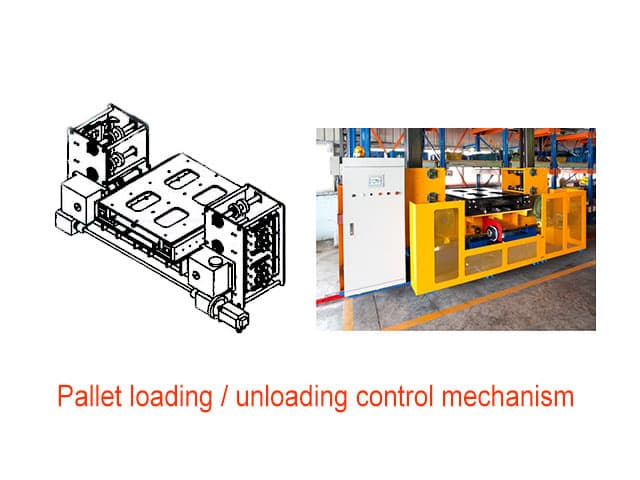

The main operations performed by automatic stacker cranes can be divided into three main classes: operations to retrieve a storage unit from conveyors; operations for unloading and loading storage units into shelving structures; delivery of a storage unit to the picking and ordering area.

This organization of work allows you to get the maximum storage density and ensure the complete safety of storage units.

Computer-controlled automated warehouse allows you to reduce labor resources and production expenses. Based on the many advantages the system of automated warehousing and storage is widely used internationally. Automation plays central role in the control system.

Two types of product storage are now most common:

- On pallet rack (maximum weight load ~2 tons).

- On plastic trays (maximum weight load ~40 kg).

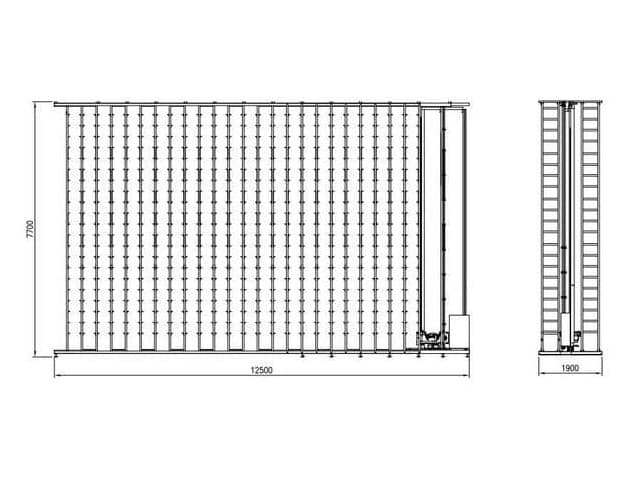

Automated warehouse for storage of finished products on euro pallets

Features

- Control mode: automatic, human-machine interface.

- Lifting mechanism (crane) control mode: manual.

- Smooth movement along X - Y - Z coordinates.

- Exact positioning.

- Convenient management interface, HMI.

- Servo motor.

- Ability to remotely monitor and control the system

Main technical characteristics

| Horizontal movement speed (max.) | 15 m/min |

| Vertical movement speed (max.) | 5 m/min |

| Number of horizontal pallets | 24 |

| Number of vertical rows | 21 |

| Number of plastic containers (trays) | 1008 pcs |

| Dimensions (L × W × H)(* see Note) | 12500 × 1900 × 7700 mm |