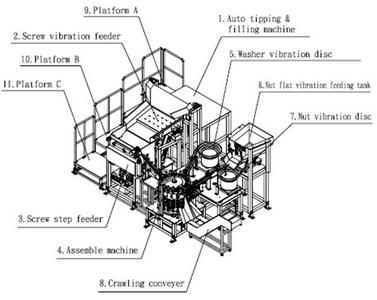

AUTOMATIC ASSEMBLY EQUIPMENT FOR FASTENERS, METALWARE AND PARTS

BOLT, NUT AND WASHER ASSEMBLY MACHINE

The principle of operation of the equipment

The first stage. Feeding of bolts. Feeding of bolts by tilting device is performed manually. To start tilting device press the "Start" button. Tilting device automatically rises and upsets the bolts in the vibratory hopper. Due to the vibration mode steady moving forward of bolts is achieved from vibrating hopper in the direction to the assembly sector.

The second stage. During forward movement of products from the hopper to the assembly sector the bolts are fixed in vertical position for vertically feeding to the assembly sector. Positioning is achieved by vibration along the slides crimping bolt rod from both sides.

The third stage. Feeding of nuts. Feeding of nuts to disk vibratory hopper is carried out manually (max. load weight 250 kg), and then due to the vibration mode steady moving forward of nuts is achieved from vibrating hopper in the direction to the assembly sector.

The fourth stage. Feeding of washers. Feeding of washers to disk vibratory hopper is performed manually (max. load weight 30 kg), and then due to the vibration mode steady moving forward of washers is achieved from vibrating hopper in the direction to the assembly sector.

Fifth stage. Automatic assembly. Bolts, nuts and washers come to the assembly sector, where their assembly and quality classification is performed. Production of high-quality assembly is automatically forwarded to the conveyor, while defective products are sorted out to a prearranged quick-btn-cont.

The technical description of the equipment

- Automatic tilting device for bolts.

- Vibratory feeding hopper for bolts.

- Ladder bolt feeder.

- Assembly mechanism for bolts, nuts and washers.

- Disk vibratory hopper for washers.

- Vibratory hopper for nuts.

- Vibratory disk for nuts.

- Conveyor.

- Platform А.

- Platform В.

- Platform С.

Technical specifications of the equipment

| Model | RG-82-SN |

|---|---|

| Operating Voltage | 380V / 50 Hz / 3 phases |

| Air pressure | 5.5 kgf/cm2 |

| Air consumption | 19.83 L/min |

| Assembly Efficiency | 30~50 pcs/min |

| Product Size | M20~M27 × L: 50~220 mm |

| Tipping Machine for Bolt | Max loading weight 2000 kg |

| Vibratory Bowl for Washer | Diameter of the Silo Ø600 mm, max. loading weight: 30 kg |

| Flat vibration feeding tank for nut | Max loading: 250kg |

| Machine Size | (L) 4728× (W) 3497 × (H) 2083 mm |

| Machine Weight | 6180 kg |