NUT COLD FORMING MACHINES

COLD HEADERS FOR NUTS

For the production of M6 and M8 nuts, five-position cold heading machines are used. For the production of M10 nuts and more, it is recommended to use six-position cold heading machines. This recommendation is based on the quality of the metal. The technology for the production of a nut from low-carbon steel on six-position presses allows to reduce the requirements for the quality of the metal and to obtain the final product of very high quality. At the same time, the consumption coefficient for metal is reduced by reducing the size of the internal die cut (otter). If the six-position machine is equipped with a transfer mechanism that allows the nut to be stamped with several turns, the result will compensate for the costs.

The six-position cold heading machine is a universal solution for the production of all groups of nuts with improved mechanical properties, excellent quality and relatively low production costs. It is important to note that the use of cold heading presses with increased positioning allows solving the problems of producing both low and high nuts, as well as nuts with a reduced turnkey size. Another advantage of six-station upsetting machines is the ability to produce special products that can give a company the freedom to expand its product range. These products include spanner wrench heads, spark plug skirts for internal combustion engines, and much more.

Why do so many partners from around the world choose our equipment?

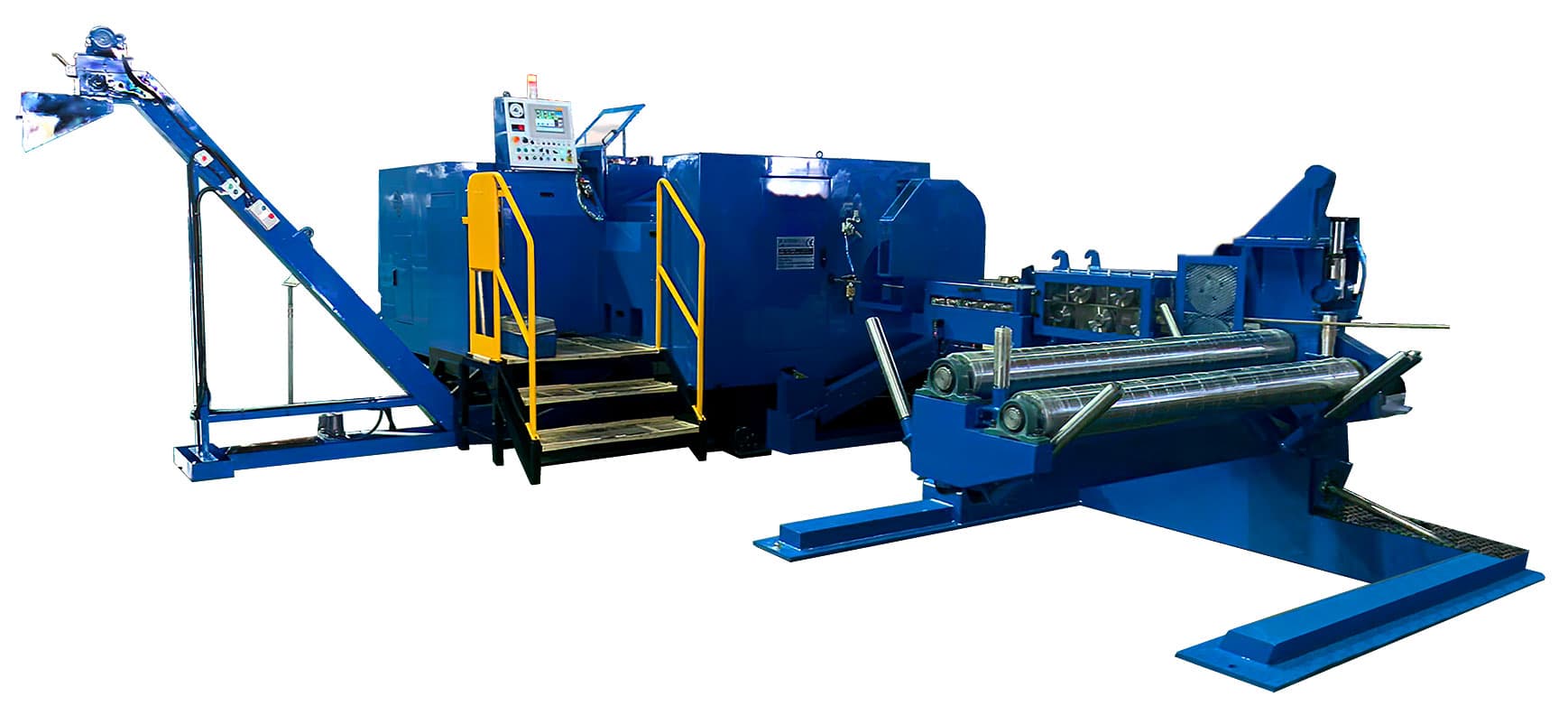

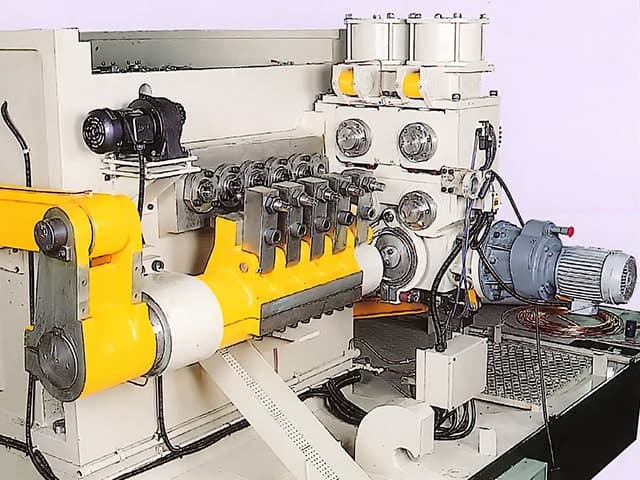

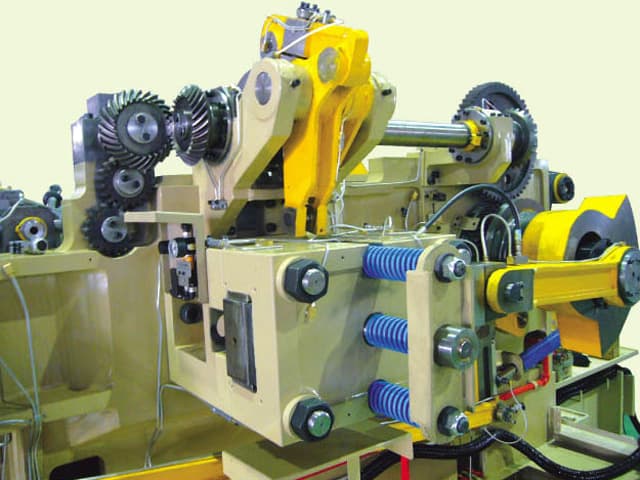

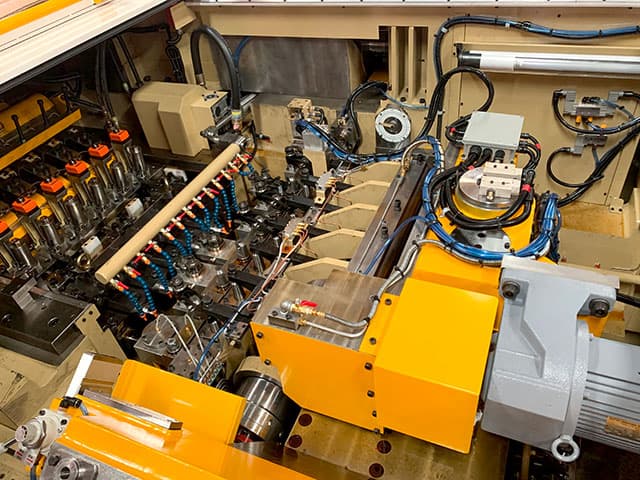

Taiwan Metiz Alliance provides equipment for nuts cold heading with 5th and 6th positional forging stations. The equipment of the new generation provides a quick products heading process. The chuck of blank feeding can be moved rectilinearly or rotated 180 degrees, depending on the requirements and characteristics for the products. Powerful S-CAM cutting mechanism is driven directly by the crankshaft, provides accurate and consistent process of cold heading. Main sliding guide of the press provides excellent stability and ensures precise linear advancement of the blank through the cutting stamps and matrices. The equipment produces nuts of cut diameter from M5 to M45. Machines are equipped with pneumatic clutch and brake systems, speed adjustment is controlled by an inverter. More than 3,000 pieces of equipment of this category is used in production worldwide.

Nut cold heading machine RNFR-32B5S series

Features of Cold Heading Machines for the Production of Nuts

Our cold heading equipment for the manufacture of nuts has a number of features:

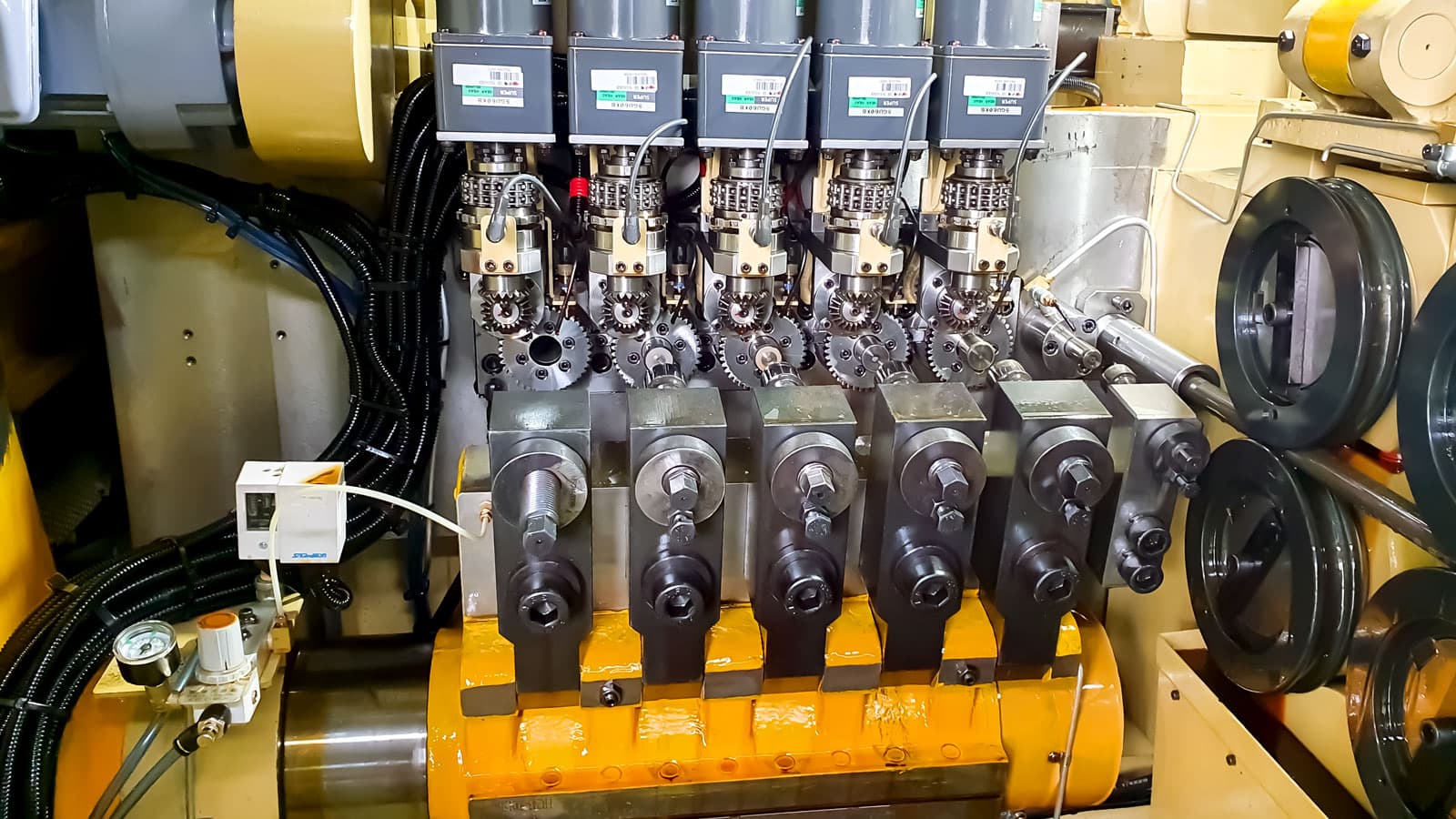

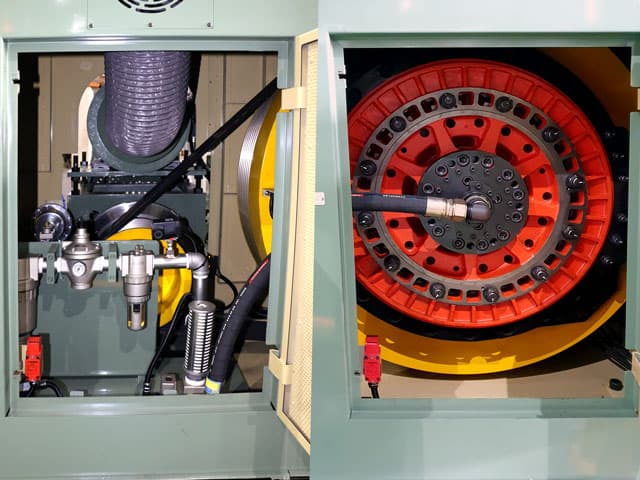

- the crankshaft with the bushing is connected to the coolant supply system at high pressure, which increases the service life of the working parts of the heading machine;

- the equipment is stopped by a pneumatic brake with a clutch. The pneumatic clutch and braking device allows the cold heading machine to be started in the setting modes, single stroke and continuous operation without damaging the electrical parts of the machine and the engine;

- P.K.O. system

- programmable operator interface displays production information, produces production counting and tool life monitoring, simplifies production monitoring of equipment condition;

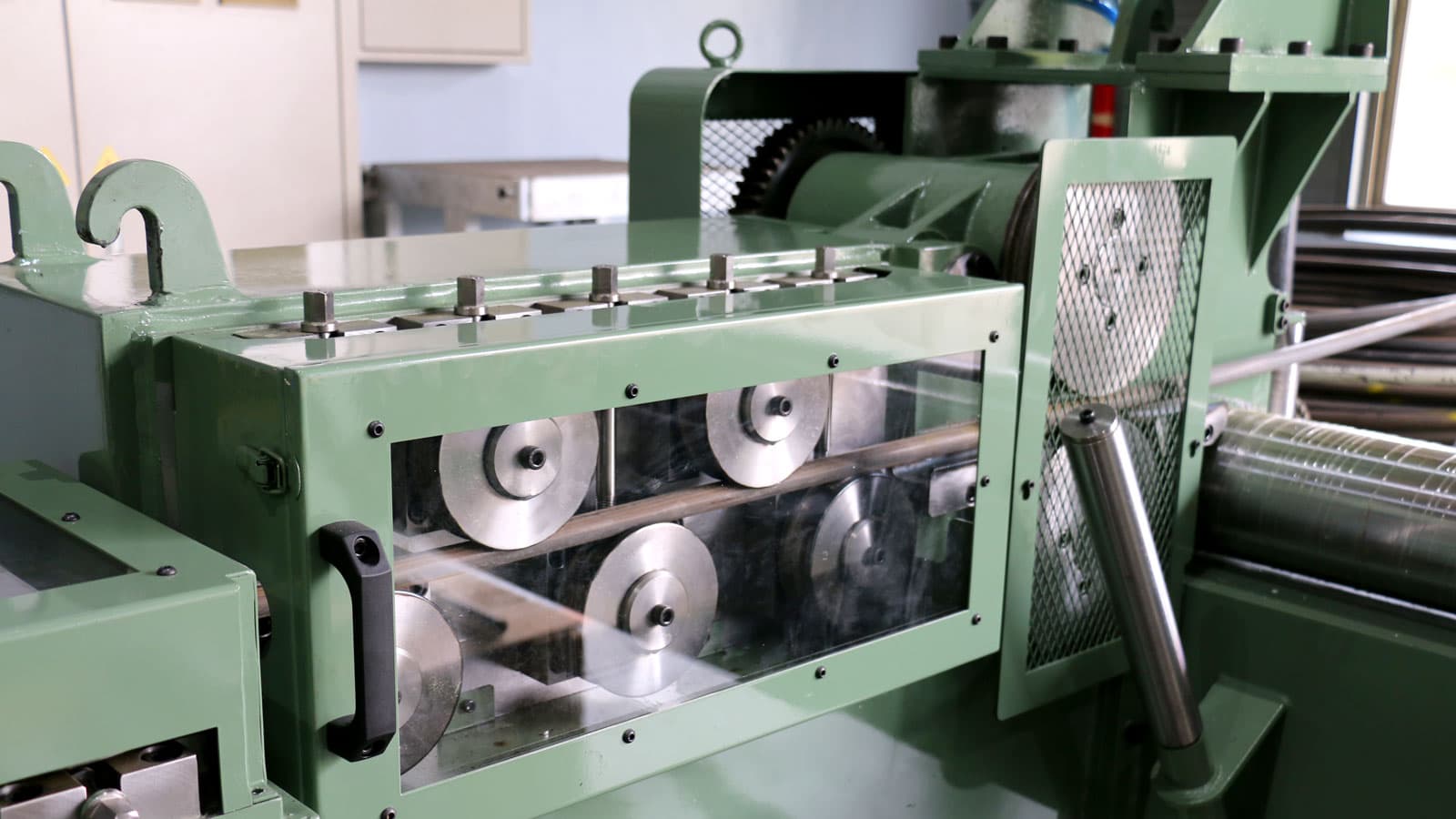

- Precise linear wire feeder with advantages over roller mechanisms: no wire slippage and no scratches or transverse imprints, increased feed accuracy, the ability to feed short and long workpieces, and the ability to feed soft materials without damaging or deforming their surface. The linear feed system also provides greater accuracy of cut workpieces by eliminating the brake and clutch problems of a traditional feed mechanism;

- speed change is controlled by an inverter;

- fault detector: in the presence of deviations in the operation of the equipment, an audible alarm mechanism is triggered, notifying the operator of possible problems.

RNFR-24B5S Nut Former Operator Panel

Operator for setting up a cold heading machine RNFR-32B5S

Wire feed unit and straightening device of RNFR-24B5S nut upsetting machine

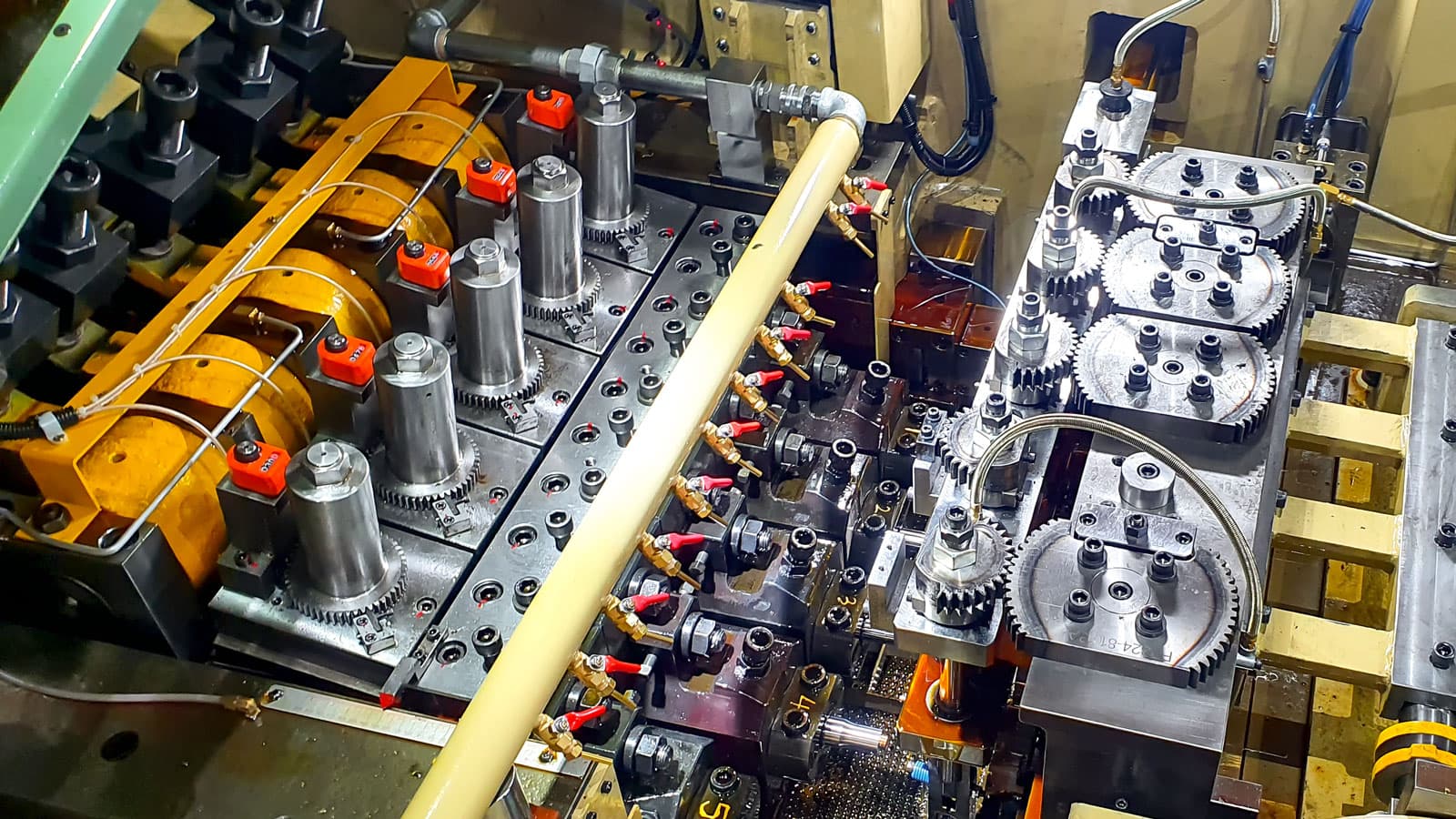

RNFR-32B5S PKO cam with 3-shift stroke adjustment. Digital gauge for punch wedge adjustment.

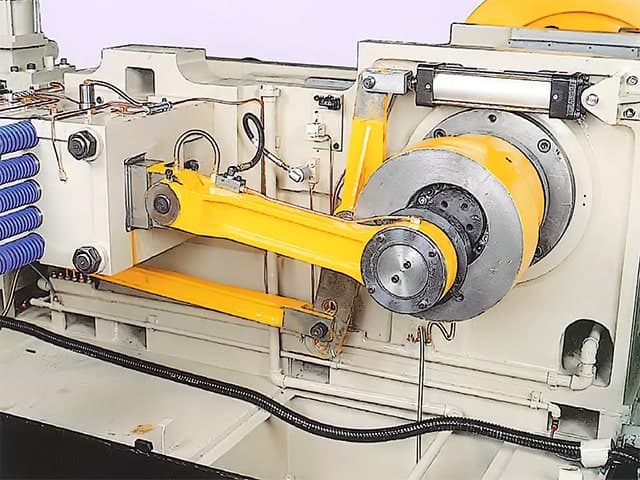

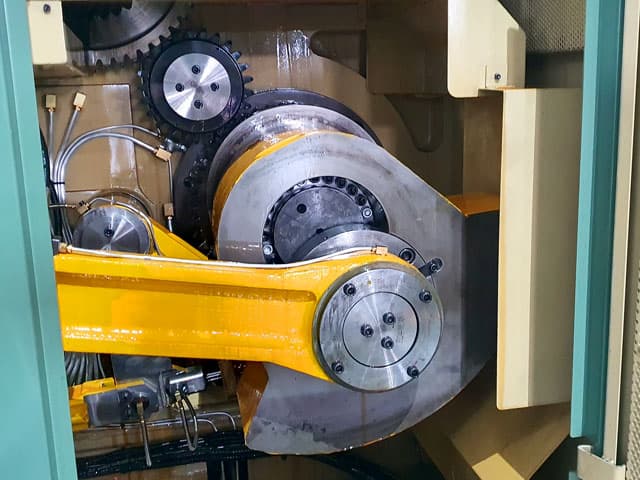

The transfer mechanism of the workpieces between positions on the RNFR-32B5S cold heading machine for the production of nuts moves straight or rotates 180 degrees depending on the requirement.

KO & stopper adjustment by 0.01mm. Motorized KO adjustment.

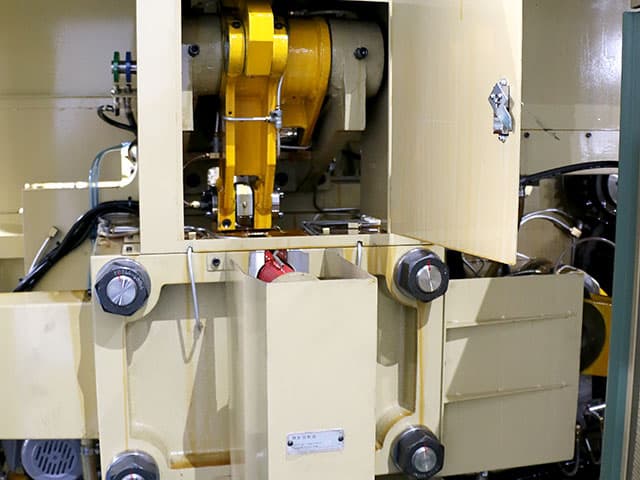

The powerful S-CAM cut-off mechanism is driven by the crankshaft and moves horizontally.

The frame provides absolute stability and straight forward process of heading

Ejection device. Cold heading machines for nuts are equipped with a die block. Retractable rods are easy to install from the die side for easy tool change.

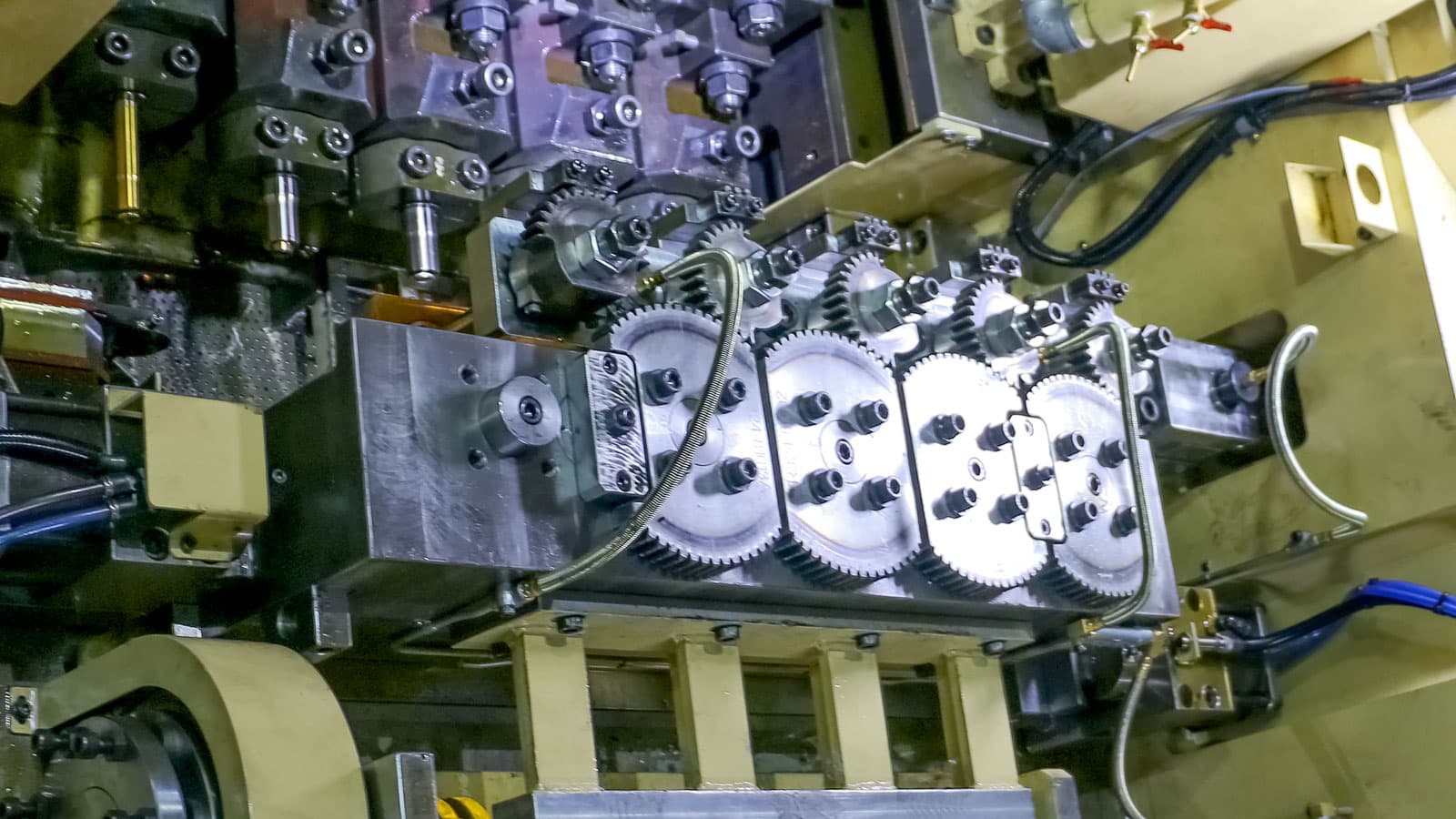

Large presses are equipped with a series of RNF cutting mechanism and pneumatic cylinders. Springs are isolated on series RNF-24B equipment of smaller size.

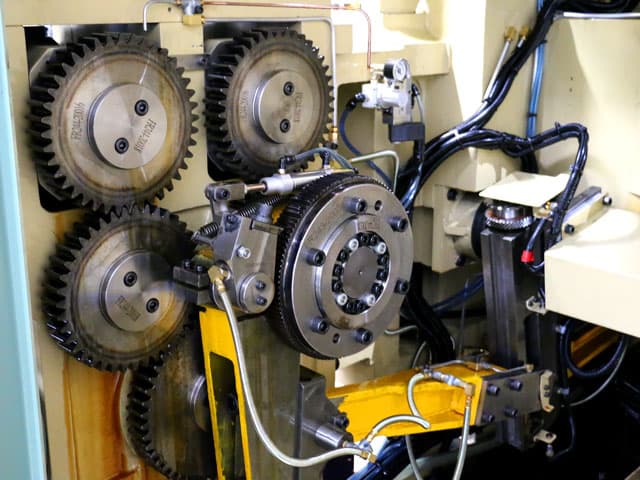

Aluminum alloy bushing for the crank & brass lining for the ram.

Large presses are equipped with a series of RNF cutting mechanism and pneumatic cylinders. Springs are isolated on series RNF-24B equipment of smaller size.

Transmission mechanisms are moved to the opposite side of operation stand to create more moving room and better view angle for operators.

Technical Specification of Cold Forming Equipment for Nuts

| Model of Nut Former | Number of Forging Stations | Nut parts specification | |

|---|---|---|---|

| Product Size | Output | ||

| RNF Series Nut Former | 5 / 6 | M5 - M30 | 48-360 pcs / min |

| RNL Series Long Stroke Nut Former | M8×25 - M32×85, Ø8×16 - Ø46×120 | 45-200 pcs / min | |

| RNFL Series Long Stroke Nut Former | M8×25 - M32×85 | 45-200 pcs / min | |

| RNFR Series Nut Former | M5 - M30 | 45-450 pcs / min | |

| RNFRL Series Long Stroke Nut Former | 6 | Ø8×20 - Ø42×100 | 50-200 pcs / min |

| RNFP Series Nut Former | 5 / 6 | M5 - M30 | 45-380 pcs / min |

| RNFPL Series Long Stroke Nut Former | Ø8×20 - Ø46×100 | 45-200 pcs / min | |

| RPF Series Long Nut Parts Former | Ø8×20 - Ø44×100 | 45-180 pcs / min | |

| RNP Series Nut Parts Former | 5 / 6 / 7 | Ø14 - Ø62 | 55-255 pcs / min |

| RLS Series Station Long Nut Former | 5 / 6 | M5 - M30 | 48-280 pcs / min |

Operation video of multi-station cold heading machines for nut production

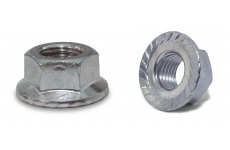

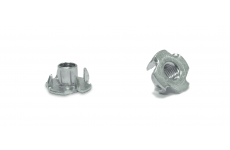

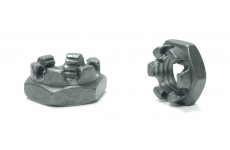

Products manufactured on Nut Formers

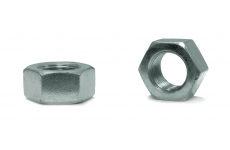

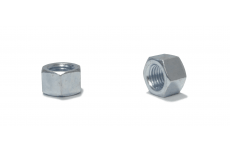

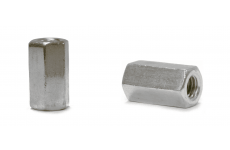

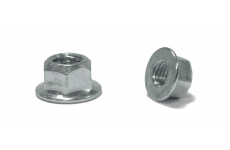

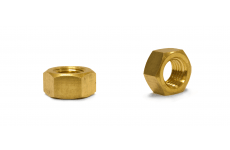

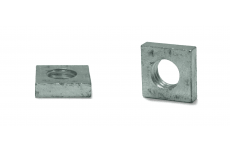

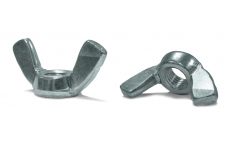

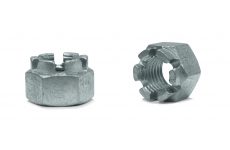

The multi-station cold heading equipment can produce a wide range of nuts and nut products in sizes M5, M6, M8, M10, M12, M16, M18, M22, M24, M27, M30, M32 with a productivity from 45 to 450 products per minute:

These products are produced on RNF Series equipment with 5, 6-position forging stations.

Product Size from M5 to M30.

These products are produced on RNL series equipment with 5, 6- position forging stations.

Product Size from M5 to M30.

Manufacturing Facility with installed Nut Formers

Machine Tool for cold heading machines

Taiwan Metiz Alliance supplies a full range of tools for cold heading machines for the production of nuts: a wide range of punches and dies for upsetting, carbide tools for cold heading (knives, cut-off sleeves, carbide inserts and cores), ejectors, pushers, cut-off knives, sleeves, clips, bushings, parts according to customer drawings (complex tools and auxiliary equipment), machine parts (rollers and prisms of wire feeders, holders of dies and punches, wear parts and spare parts for various types of equipment).