Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

COLD FORMING MACHINERY FOR MICRO FASTENERS

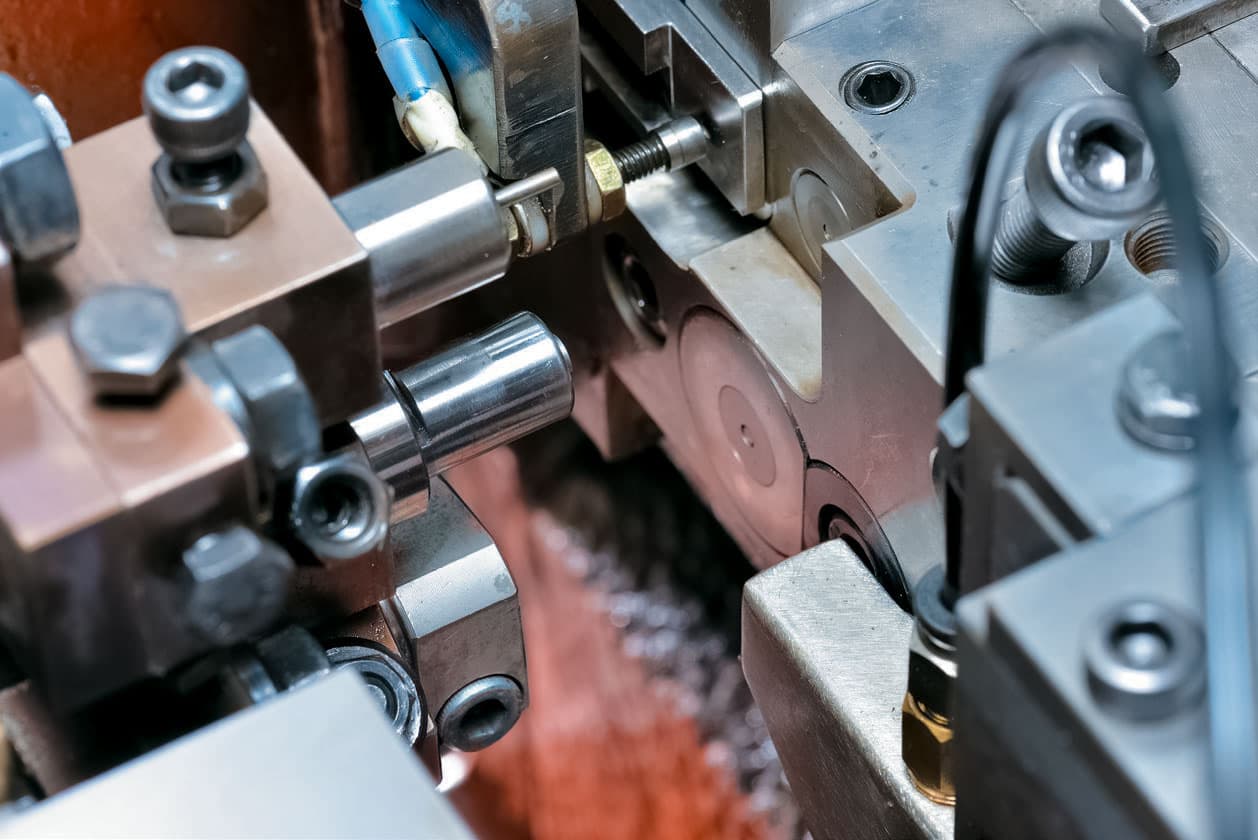

1-Die 2-Blow Micro Cold Heading Machine for Micro Screw

Сost-effective 1-Die 2-Blow Cold Heading Machines for high precision manufacturing of standard micro fasteners with wire diameters from 0.5 to 5.3 mm.

The machines are equipped with a protective cover to prevent contamination of the interior with oil and dust.

- Designed for short, small diameter fasteners with a thin head.

- Die transfer without gripper: ideal for short products.

- Bush cut-off construction for a perfectly flat surface even with hard materials.

- Separately operated punches for faster and easier setup.

1-Die 2-Blow Cold Heading Machines are suitable for wire diameters from Ø0.5mm to Ø5.5mm.

With wire diameters less than Ø4.5 mm, material transmission method without clamp over-die is used.

For wire diameter Ø5.5mm we offer 2 different material transfer methods according to product length specifications, and there are fixture over-die and no-clamp over-die.

What is a non-clamp over-die?

Round shear break => material ejection => 1 blow transfer to 1 die

Technical Specification

| Model No. | RG-105A | RG-110A | RG-115 | RG-120 | RG-200F |

|---|---|---|---|---|---|

| Transfer | Gripper-free Transfer | Gripper | |||

| Wire Diameter (mm) | Ø0.5 - Ø2.2 | Ø1.6 - Ø3.5 | Ø2.2 - Ø4.5 | Ø2.6 - Ø5.3 | |

| Cut-off Length (mm) | 2 - 14 | 3 - 25 | 3 - 35 | 5 - 40 | 40 - 90 |

| KO Length (mm) | 14 | 16 | 25 | 30 | 76 |

| Output (Free Run) (pcs/min) | 80 - 220 | 80 - 150 | 80 - 120 | 80 - 110 | |

| Main Stroke (mm) | 36 | 60 | 92 | 120 | |

| Up/Down Stroke (mm) | 26 | 32 | 40 | 45 | |

| 1st PKO Stroke (mm) | - | -* / 12 | - | ||

| 2nd PKO Stroke (mm) | 6(* see Note) / 9 | 12 | - | ||

| Main Motor (HP) | 2HP - 4P | 3HP - 4P | 5HP - 4P | 5HP - 6P | |

| Main Die Diameter (mm) | Ø30×35.3L | Ø38×50.3L | Ø38×80.5L*/65L | Ø42×100.5L | |

| 1st Punch Diameter (mm) | Ø18×50L | Ø22×65L | Ø31×75L*/90.5L | Ø36×93L | |

| 2nd Punch Diameter (mm) | Ø18×65L | ||||

| Pusher / Quill Diameter (mm) | Ø14 / Ø12 | Ø15 / Ø15 | Ø15 / Ø17 | Ø15 / Ø22 | |

| Cutter Dimensions (mm) | 6H×20W×58L | 8H×24W×76L | 9H×32W×75L | 10H×38W×83L | 10H×38W×75L |

| Net Weight (kg) | 1000 | 1350 | 1650 | 2200 | 2350 |

| Overall Size (cm) | 210×120×175 | 225×120×180 | 225×125×185 | 250×155×185 | |

| Optional Accessories | |||||

| Model No. | RG-105A | RG-110A | RG-115 | RG-120 | RG-200F |

| HMI System (Set) | option | option | option | option | option |

| Auto Wire Feeder (Set) | option | option | |||

| Parts Catcher System (Set) | option | option | |||

| PKO System (Set) | option | option | option | option | option |

| DDKO System (Set) | option | option | option | option | |

| Rotary Collector (Set) | option | option | |||

Video of the operation of cold heading equipment for the production of micro products

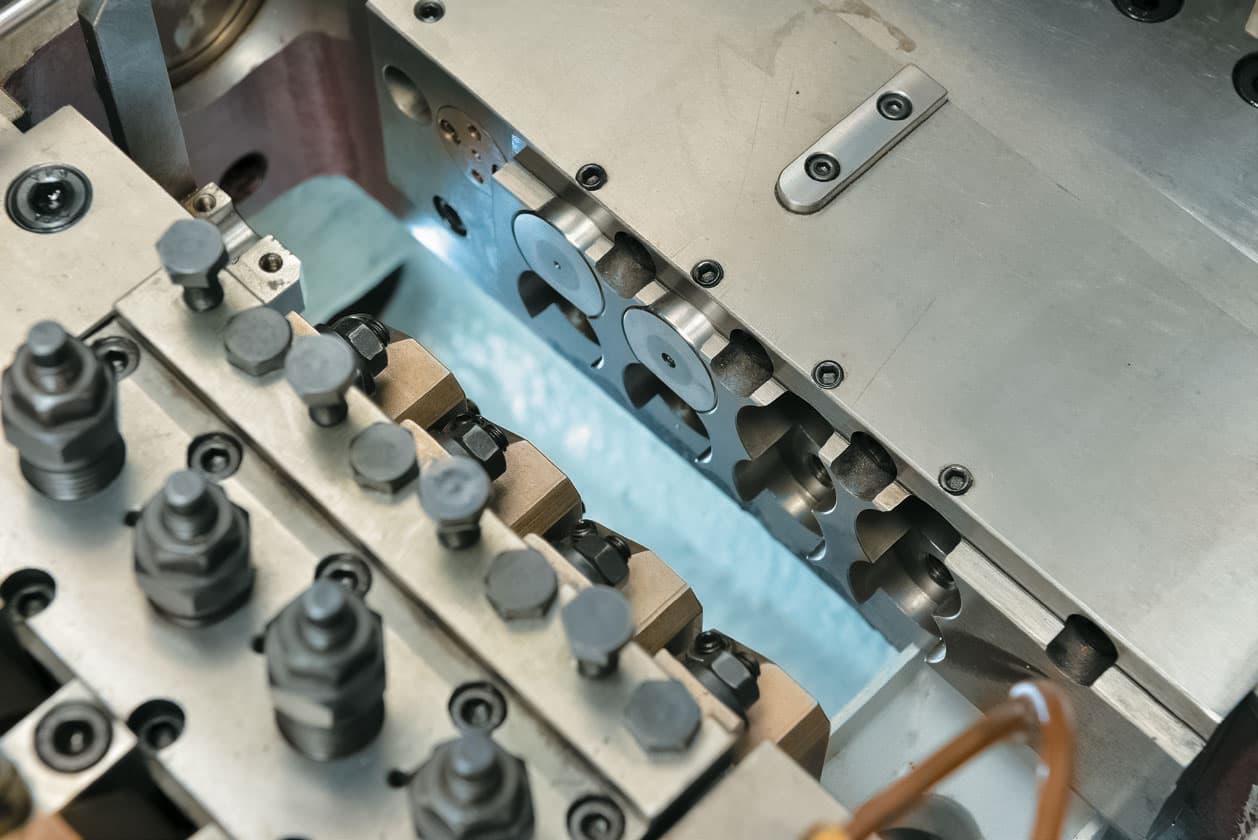

2-Die 3-Blow Micro Cold Forming Machines

2 dies and 3 forming stations allow the production of relatively complex micro-parts. On such a machines, it is possible to effectively produce micro fasteners with a wire diameter of 0.5 - 4.5 mm. These machines is equipped with a protective cover to prevent contamination of the interior with oil and dust.

- Suitable for cold heading short fasteners with a small diameter and a thin head.

- Die-transfer without gripper ideal for short workpieces.

- Bush cut-off design for a perfectly flat surface even when working with hard materials.

- Separate operating punches for faster and easier setup.

- The separated die holder can adjust the concentricity independently.

- The material-receiving function can prevent material collision and the 2 blow/ 3 blow can set monitoring accuracy independent.

- The Double D.K.O. device (optional) can improve the roundness and fullness of the head forming.

The RG-1305 Micro cold forming machine is suitable for very precise and short workpieces. The material transfer mode is designed without clamping over the die, through materials with two punches to transfer materials from the first die to the second die after the completion of the three-die production. The ideal vacuum feeding device instantly transfers the finished product to the collection box, which can prevent splashing, smearing, lack of product, material leakage and mixing problems.

Offered 2 different material transmission methods for different choices according to the different length specifications of the product. RG-1310F has fixture over-die and RG-1310 has no-clamp over-die.

The separated die holder can adjust the concentricity independently. The material-receiving function can prevent material collision and the 2 blow/3 blow can set monitoring accuracy independent.

Technical Specification

| Model No. | RG-1305 | RG-1310 | RG-1315L | RG-1310F |

|---|---|---|---|---|

| Transfer | Gripper-free Transfer | Gripper | ||

| Wire Diameter (mm) | Ø0.5 - Ø2.2 | Ø1.6 - Ø3.5 | Ø2.2 - Ø4.5 | Ø1.6 - Ø3.5 |

| Cut-off Length (mm) | 2 - 14 | 3 - 25 | 3 - 30 | 3 - 25 |

| 1st KO Length (mm) | 14 | 19 | 40 | - |

| 2nd KO Length (mm) | 16 | 25 | 16 | |

| Output (Free Run) (pcs/min) | 80 - 180 | 80 - 150 | 80 - 120 | |

| Main Stroke (mm) | 36 | 60 | 92 | 60 |

| Up/Down Stroke (mm) | 26 | 32 | 40 | 32 |

| 2nd PKO Stroke (mm) | - | -* / 12 | - | |

| 3rd PKO Stroke (mm) | 6(* see Note) / 9 | 12 | - | |

| Main Motor (HP) | 2HP - 4P | 3HP - 4P | 5HP - 4P | 3HP - 4P |

| 1st Die Diameter (mm) | Ø14×25L | Ø15×34L | Ø22×62L | Ø20×47L |

| 2nd Die Diameter (mm) | Ø30×35.3L | Ø38×50.3L | Ø38×80.5L*/65L | Ø30×50.3L |

| 1st Punch Diameter (mm) | Ø14×50L | Ø16×65L | Ø18×75L | Ø16×65L |

| 2nd Punch Diameter (mm) | Ø18×50L | Ø26×65L | Ø28×75L*/90.5L | Ø26×65L |

| 3rd Punch Diameter (mm) | Ø18×65L | Ø25×75L*/90.5L | Ø18×65L | |

| Pusher / Quill Diameter (mm) | - / Ø12 | - / Ø15 | - / Ø19 | Ø15 / Ø15 |

| Cutter Dimensions (mm) | 6H×20W×58L | 8H×24W×76L | 9H×32W×75L | 8H×24W×70L |

| Net Weight (kg) | 1000 | 1350 | 1600 | 1350 |

| Overall Size (cm) | 210×120×175 | 225×120×180 | 225×125×185 | 225×120×180 |

| Optional Accessories | ||||

| Model No. | RG-1305 | RG-1310 | RG-1315L | RG-1310F |

| HMI System (Set) | option | option | option | option |

| Auto Wire Feeder (Set) | option | option | option | |

| Parts Catcher System (Set) | option | option | ||

| PKO System (Set) | option | option | option | option |

| DDKO System (Set) | option | option | option | |

| Rotary Collector (Set) | option | option | ||

Multi-Station Micro Formers

- High-precision mechanism designed for cold heading very small precision parts. It has high rigidity for long-term accurate maintenance and can ensure the overall assembly accuracy within 10 µm or less.

- The machine can control the accuracy of the assembly step, each with an accuracy of 5µm or less.

- The machine can control the die block pitch accuracy to 5µm or less.

- A structure is used that can adjust the finger's transfer pitch with higher accuracy.

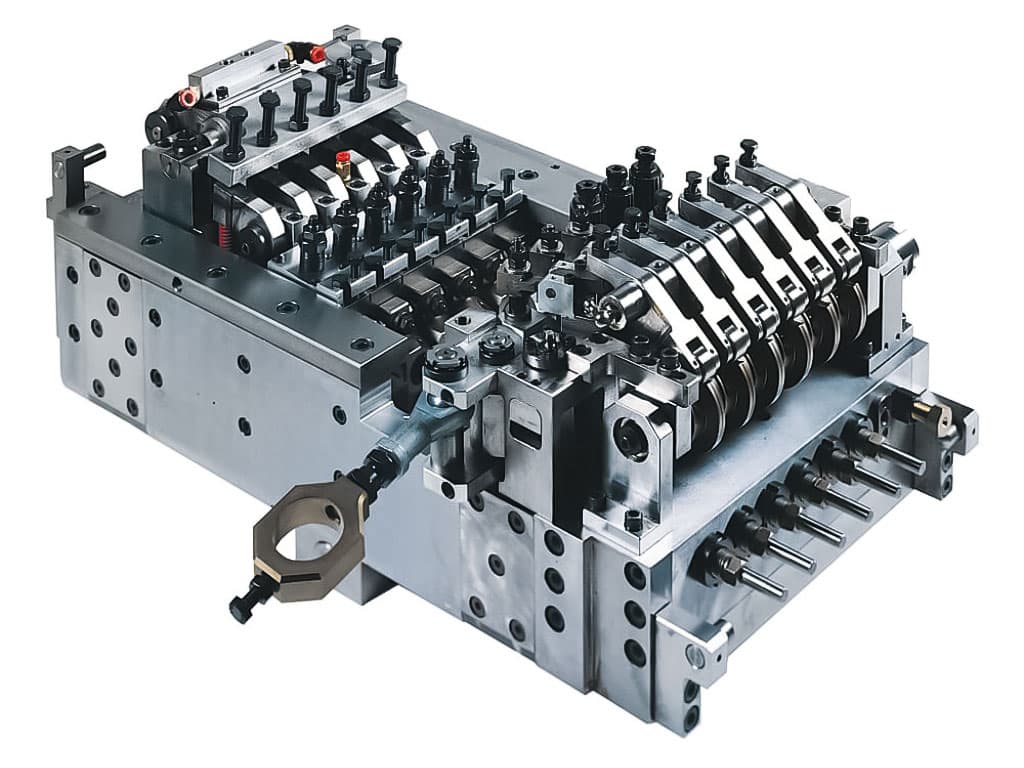

4-Die 4-Blow Micro Former RG-4P

The machine is designed for complex cold forming operations required for the manufacture of complex micro-parts. 4 forming stations make it possible to produce a wide range of shapes with a wire diameter of 0.8 - 3.0 mm. The machine is equipped with a protective cover to prevent contamination of the interior with oil and dust.

- For advanced complex micro forming operations.

- Clamp die transfer.

- Flexible transfer options: translational, rotating, turning.

- Lightweight clamp design provides secure gripping of very small parts down to 0.7mm in diameter.

6-Die 6-Blow Micro Former RG-6P

The machine is designed for complex cold heading operations required for the manufacture of very complex micro-parts from 0.8 - 3.0 mm. The machine is equipped with a protective cover to prevent contamination of the interior with oil and dust.

- 6 forming stations make it possible to produce a wide range of shapes with a wire diameter of 0.8 - 3.0 mm.

- High precision, low vibration and noise.

- Flexible advanced production of various types of micro fasteners.

- The die cassette change system allows changing in 10 minutes for increased productivity.

- High production flexibility: for new types of products, only the replacement of the die cassette is required.

Technical Specification

| Model No. | RG-4P | RG-6P |

|---|---|---|

| Transfer | Active / Passive Gripper | |

| Number of Dies | 4 | 6 |

| Number of Punches | ||

| Wire Diameter (mm) | Ø0.8 - Ø3 | |

| Cut-off Length (mm) | 2 - 25 | |

| KO Length (mm) | 25 | |

| Output (Free Run) (pcs/min) | 80 - 200 | |

| Main Stroke (mm) | 70 | |

| Rotation Length (mm) | 15 | |

| PKO Stroke (mm) | 6(* see Note) / 9 | |

| Main Motor (HP) | 5HP - 6P | |

| Main Die Diameter (mm) | Ø25×70L | |

| Punch Diameter (mm) | Ø20×48L | |

| Pusher / Quill Diameter (mm) | Ø23 / Ø14 | |

| Cutter Dimensions (mm) | 6H×25W×42.5 | |

| Net Weight (kg) | 2000 | |

| Overall Size (cm) | 291×155×170 | 285×155×170 |

| Optional Parts | ||

| Model No. | RG-4P | RG-6P |

| HMI System (Set) | option | option |

| Stripper System (Set) | option | |

| Auto Wire Feeder (Set) | option | standard |

| Mini Cassette (Set) | option | |

| Hoist (Set) | option | |

| Trolley (Set) | option | |

| Rotary Collector (Set) | option | option |

Cold heading machine for bi-metal RG-05MB

This 2-Die 3-Blow types of cold forming machine is for silver joint double material and double round shear break.

This can achieve better cut surface quality, and the material can be made of material whose outer diameter within minimum 0.7mm. The shortest cut length is 0.7L, which can be used for customers for their applications.

This model saves the expensive cost of precious metal (silver) materials and provides customers with higher profit margins.

Double DKO System with additional stroke increase fullness for the finished products without adding material and tool modification.

Technical Specification

| Model No. | RG-05MB |

|---|---|

| Transfer | Gripper-free Transfer |

| Wire Diameter (mm) | Ø1.2 - Ø3.5 |

| Cut-off Length (mm) | Ag 0.5 - 5 Cu 1.5 - 12 |

| Total Cut-off Length (mm) | 2 - 12 |

| 1st KO Length (mm) | 12 |

| 2nd KO Length (mm) | |

| Output (Free Run) (pcs/min) | 80 - 150 |

| Main Stroke (mm) | 60 |

| Up/Down Stroke (mm) | 32 |

| 3rd PKO Stroke (mm) | 6(* see Note) / 9 |

| Main Motor (HP) | 3HP - 6P |

| 1st Die Diameter (mm) | Ø14×36L |

| 2nd Die Diameter (mm) | Ø30×50.3L |

| 1st Punch Diameter (mm) | Ø16×65L |

| 2nd Punch Diameter (mm) | Ø26×65L |

| 3rd Punch Diameter (mm) | Ø18×65L |

| Pusher / Quill Diameter (mm) | - / Ø15 |

| Cutter Dimensions (mm) | 10H×24W×76L |

| Net Weight (kg) | 1350 |

| Overall Size (cm) | 225×120×180 |

Combined micro cold heading and micro thread rolling machine RG-05H

One of the important features of this machine is the vacuum transport system. From the cold heading station, the blanks are immediately transferred to the drum of a rotary feeder using an advanced vacuum transport system. Further, the workpieces are continuously fed to the thread rolling station to form the thread.

Technical Specification

| Model No. | RG-05H |

|---|---|

| Transfer | Gripper-free Transfer |

| Wire Diameter (mm) | Ø0.8 - Ø2 |

| Cut-off Length (mm) | 2 - 6 |

| KO Length (mm) | 6 |

| Output (Free Run) (pcs/min) | 80 - 220 |

| Main Stroke (mm) | 36 |

| Up/Down Stroke (mm) | 26 |

| 2nd PKO Stroke (mm) | 6(* see Note) / 9 |

| Feeding Type | Header (Feeding Rollers) / Thread Roller (Flat) |

| Main Motor (HP) | Header / 2HP - 4P |

| Main Motor (kW) | Thread Roller / Servo Motor: 0.9 |

| Main Die Diameter (mm) | Ø30×35.3L |

| 1st Punch Diameter (mm) | Ø18×50L |

| 2nd Punch Diameter (mm) | |

| Pusher / Quill Diameter (mm) | Ø14 / Ø12 |

| Cutter Dimensions (mm) | 6H×20W×58L |

| Fixed Die Dimensions (mm) | 15W×15H×40L |

| Moving Die Dimensions (mm) | 15W×15H×50L |

| Net Weight (kg) | 1800 |

| Overall Size (cm) | 220×130×200 |

Optional Accessories for Micro Cold Heading Machines

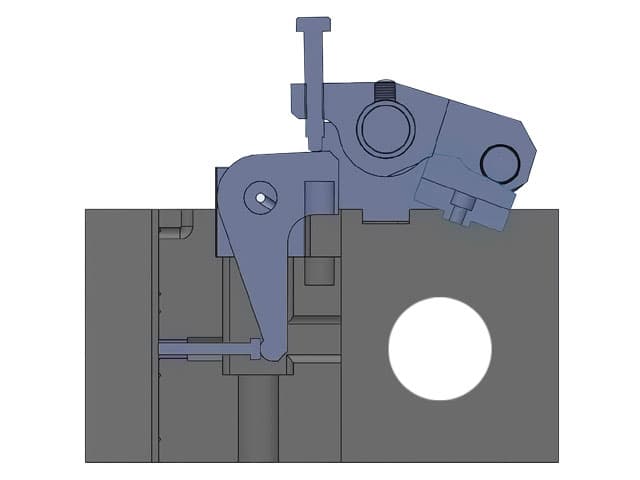

PKO System

- After punch completion, at the same time as the main slide retreats, PKO engages.

- Cam-driven punch knock-out system.

- Suitable for a wide range of die designs.

- With the front PKO device installed, the second die is finished stamping, and the main sliding seat is ready to be retracted at the same time for PKO, which effectively prevents die sticking.

HMI Control Panel

- User-friendly 7-inch touch panel.

- Error notification & record feature.

- Production data can be downloaded.

- Tooling and Spare Part status reminder.

- Easy to control cost and maintain machine accuracy.

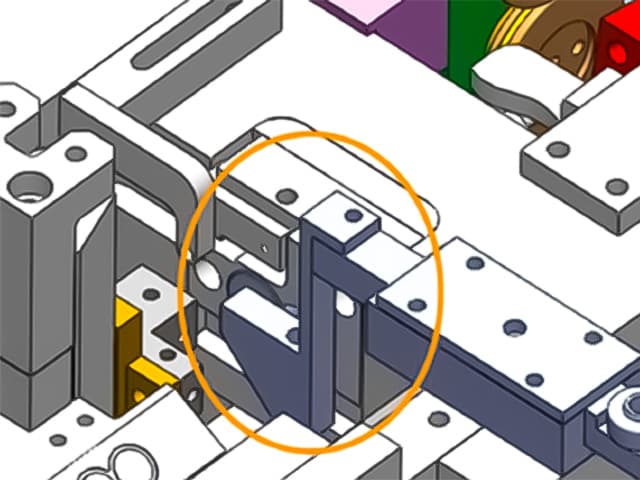

Double D.K.O. System

- The Double D.K.O. device (optional) can improve the roundness and fullness of the head forming.

- Additional stroke for even more precise forming results.

- Customizable designs available according to production requirements.

Parts Catcher System

Perfect for small and short part, which is sucked and transferred into output box instantaneously to prevent contaminated with oil and Ieackage of materiall when forming is complete.

- Especially suitable for small & short workpieces

- Automatically collects the finished part right after forming

- Protects your finished products from contamination (oil, etc.)

Rotary Collector

- Prevents mixing of defective and quality products. Simplifies the work of quality control personnel. Allows regular sampling and analysis during the production process.

- Allows to control the finished product by batch. The disc rotation time can be adjusted according to the quantity of products or according to time.

- Reduces the frequency of unloading finished products.

Auto Wire Stand

Automatic wire feeding with brake positioning device and induction device to achieve active feeding time, single feeding quantity and thin product with diameter less than Ø1.2mm.

- Suitable for wire diameters up to 1.2 mm

- Increased productivity and fastener quality thanks to smooth feeding into the machine

- No short blanks & no material wasted

- Prevent wire deformation due to tension.

- Prevent the material from pulling down.

- Ensures accurate feed length and prevents wire from being pulled back.

- Numerically displays the feed fine-tuning length.

- Safety brake function