HOT FORGING EQUIPMENT FOR FASTENERS, PARTS AND HARDWARE

EQUIPMENT FOR METAL HARDWARE, FASTENERS AND COMPONENT PARTS HOT HEADING

Blanks produced by hot die forging have complex shapes with high strength, durability and a wide range of steel grades used (low / medium / high carbon steel, stainless steel, alloy steel, special alloy steel), aluminum or copper alloys.

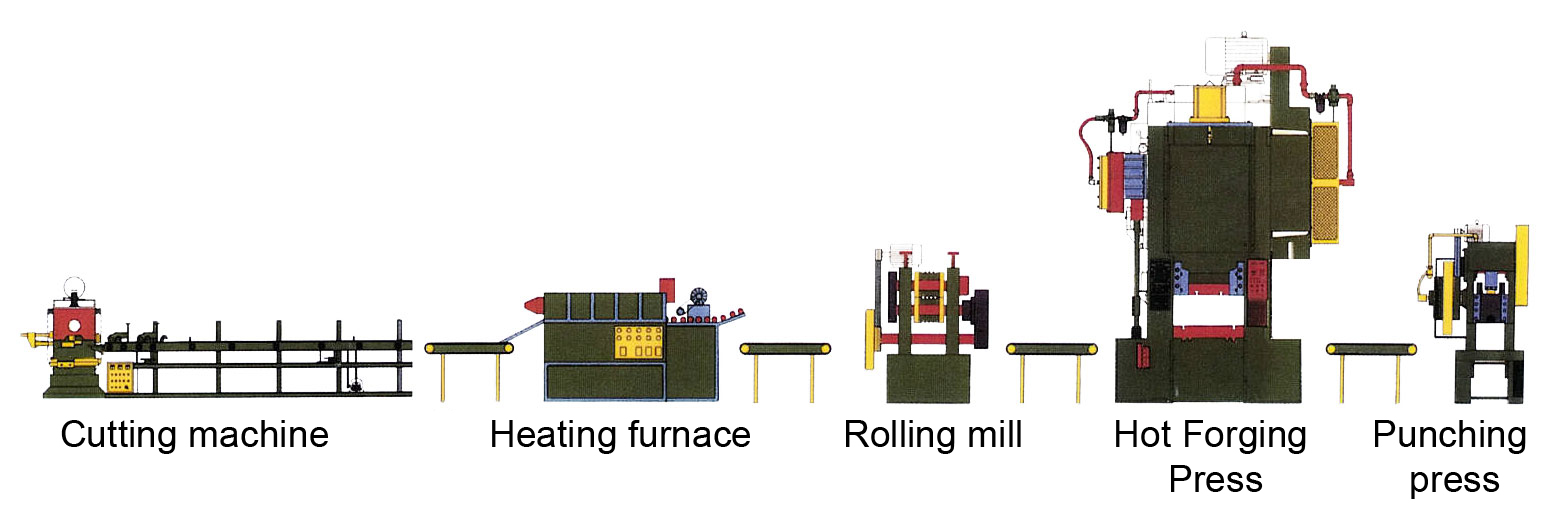

Technological process of hot stamping of hardware and fasteners

Components of the process:

- Cutting machine.

- Heating furnace.

- Rolling mill.

- Forging press.

- Parting (punching) press.

Features of equipment for hot stamping of hardware and fasteners

Equipment for fasteners, metal hardware and component parts hot heading proposed by Taiwan Metiz Alliance has the following characteristics:

- The design of the equipment minimizes the possibility of voids forming in the mold cavity and reduces metal consumption.

- High starting effort provides operational efficiency.

- High speed and precision of movements extend the service life of the mold.

- Accuracy of the equipment is confirmed by CNS standard.

- The special design of the transmission significantly reduces the noise level during press operation.

Video of the operation of the Equipment

HOT STAMPING PRODUCTION

The method of hot stamping can be obtained by: gears, rollers, spiders, caps, flanges, links, cranks, parts of isolation valves, oil industry parts, railway parts crankshafts, connecting rods, internal combustion engine details, solid-rolled rings, joint fists, tie rods, spanners, valves, stainless steel tanks, hot water tanks, equipment for spraying, metal bars and much more (see. fig.).