OPEN DIE HEADING EQUIPMENT

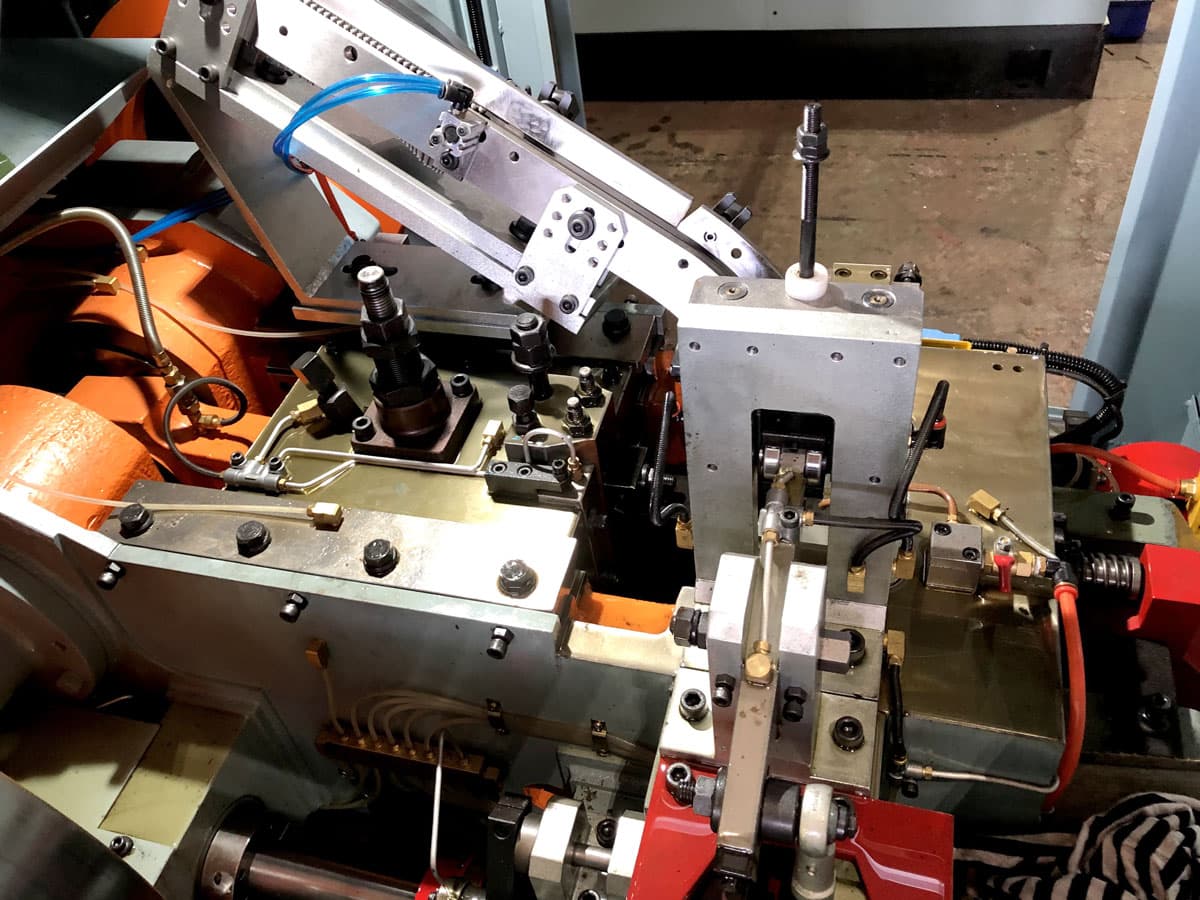

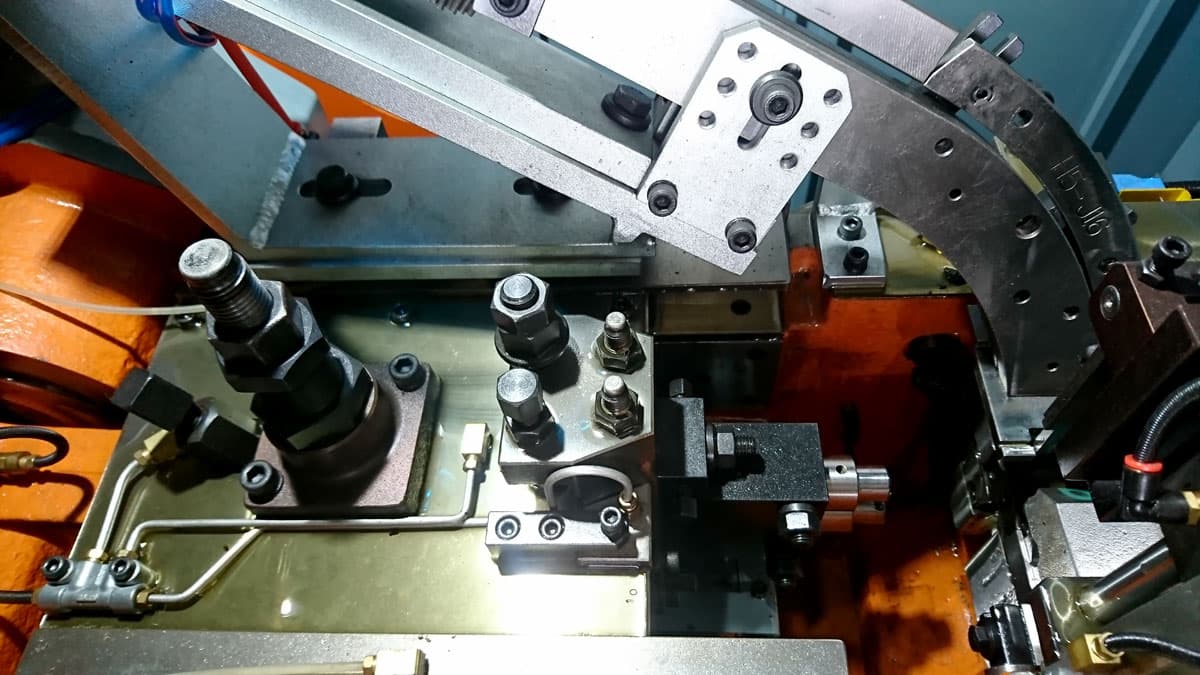

EQUIPMENT FOR SECONDARY HEADING OF HARDWARE, FASTENERS AND PARTS WITH OPEN DIE

Equipment for secondary heading of fasteners, hardware and parts is the fastest and easiest way to produce all kinds of automotive fasteners (vehicle parts, etc.), aircraft parts and special components. Whereas previously complex automotive components could only be machined using a lathe or CNC, it is now possible to do this on cold heading equipment thanks to a revolutionary open die design. The biggest advantage of the open die re-heading machine is that during the production of complex products, the percentage of waste is minimal.

Taiwan Metiz Alliance offers equipment for cold re-heading of parts and fasteners, giving the user the ability to produce precise shaped parts with complex and unique geometries.

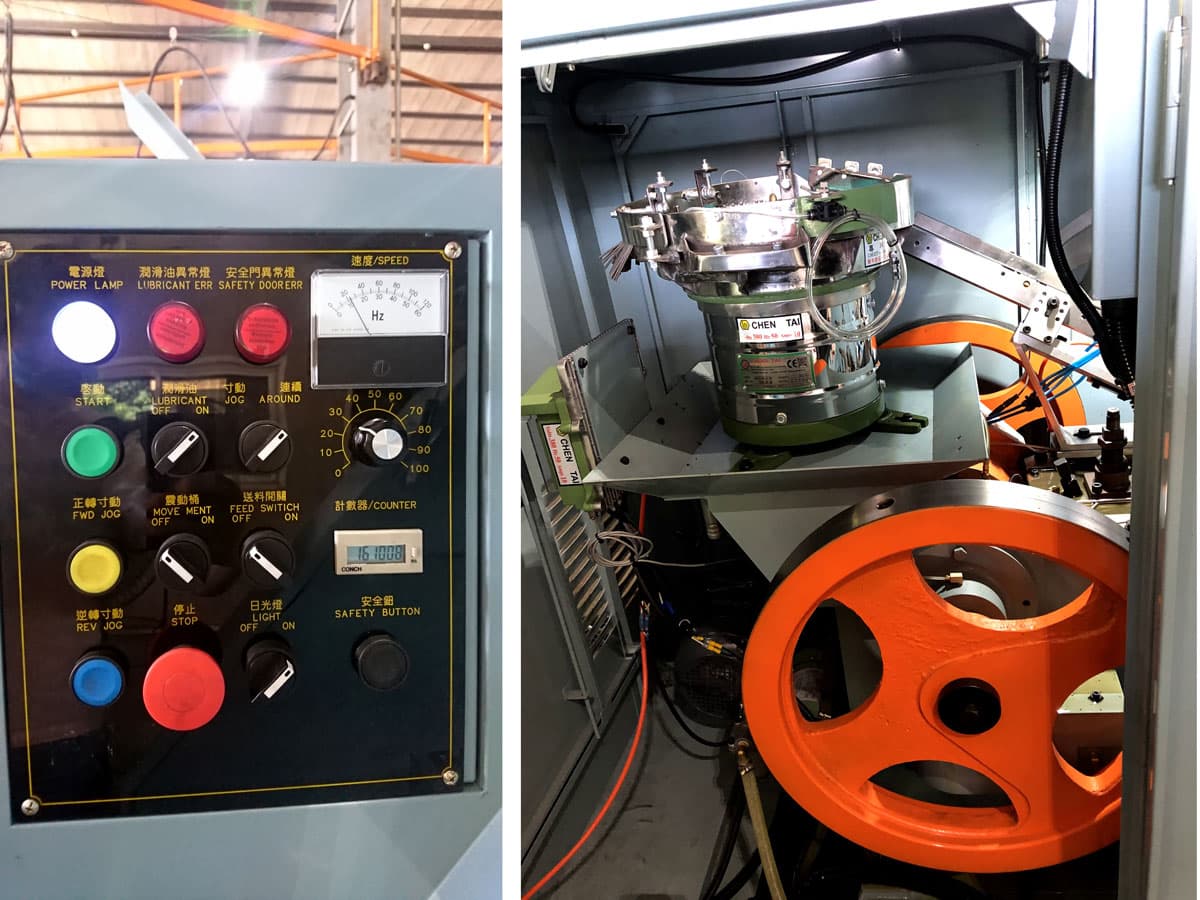

This cold heading equipment allows the secondary heading process to be carried out in two additional strikes, operates in four modes of billet feeding, depending on the shape and length requirements for the finished products. The production speed of these machines ranges from 15 to 90 units per minute, controlled by an inverter with high precision. Possibility to manufacture products with unlimited length.

Equipment control is available to the operator from the control panel. Equipped with a pneumatic clutch and brake system, the workpiece can be fed in four modes (ram side feeding, die side feeding, track/ tube feeding for headless parts, rack feeding for long parts). The stand is used for automatic feeding of large parts. There is a possibility of a complete set in a semi-protective casing and in a protective casing.

Technical characteristics of equipment for secondary heading of hardware, fasteners and parts

Model | RG/ODH5X75 | RG/ODH6X160 | RG/ODH8X200 | RG/ODH10X300 | RG/ODH15X300 |

|---|---|---|---|---|---|

| Forging effort | 20000 kg | 25000 kg | 35000 kg | 40000 kg | 60000 kg |

| Max. Wire Dia. | 3~5 mm | 4~6 mm | 6~8 mm | 6~10 mm | 8~12(15) mm |

| Max. cut length | 25~75 mm | 25~200 mm | 25~250 mm | 25~350 mm | 25~350 mm |

| Punching Diameter | 31 mm | 38 mm | 42 mm | 52 mm | 78 mm |

| Performance | 50~90pcs./min. | 30~55pcs./min. | 20~50 pcs./min. | 15~40 pcs./min. | 15~40 pcs./min. |

| Feeding mechanism | Vibrating mechanism (Single-acting type A, B or C depending on processed blank) | ||||

| Auto-feeding device length | 25~75 mm | 25~150 mm | 25~150 mm | 25~200 mm | 25~200 mm |

| Main motor | 3 HP | 5 HP | 7.5 HP | 20 HP | 50 HP |

| Parameters of the machine, mm | 1700 × 1050 × 1000 | 2600 × 1330 × 1800 | 3200 × 1510 × 1800 | 4450 × 1780 × 2000 | 7300 × 2440 × 2600 |

| Machine weight | 2100 kg | 4000 kg | 6800 kg | 13000 kg | 18000 kg |

Features of equipment for secondary heading of hardware, fasteners and parts:

- The protective cover provides acoustic insulation.

- Adjustable suspension system (height width).

- Easy setup of secondary heading parameters. The double puller prevents the workpiece from getting stuck in the heading die.

- Four feed modes. The workpiece feeding mechanism can be easily reconfigured according to the workpiece parameters.

- Pneumatic clutch and brake system.

- Heading of products of complex shapes, unlimited length.

- Low-cost tools, easy to operate.

Equipment operation video

Samples of products manufactured on open die heading equipment