CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

CONVEYOR FURNACES FOR FASTENERS

Application of heat treatment equipment

A conveyor furnace is an industrial furnace in which the product moves from the loading station to unloading on a conveyor. Continuous conveyor furnaces can perform a variety of heat treatment processes, such as cementation, carbonitriding, tempering screws, nuts, bicycle parts, hand tools, hardening of mechanical parts of automotive accessories, fasteners, chains, bearings, tools and other products and ending with a sharp cooling in oil or water, polymers and salts.

- Carburizing and hardening of metal products: self-tapping screws, self-drilling screws, wood screws.

- Hardening of fasteners (bolts, nuts).

- Thermal processing of bicycle parts, motorcycles, cars.

- Heat treatment of hand tools

GAS HEATING TYPE or ELECTRICAL HEATING TYPE ?

Before selecting a continuous furnace for heat treatment of metal products it is necessary to pre-determine for yourselves the type of heating furnace. Furnaces are of two types: electric and gas heating furnace. To calculate the cost of production is strongly recommended to study the table which shows the calculation of the cost of running the continuous furnace line (Taiwan).

Calculating the cost of operation of the continuous furnace line

- Electric furnace for bolts (700 kg/h) the source of the atmosphere methanol

- Electric furnace for screws (500 kg/h) the source of the atmosphere methanol + propane

- Gas furnace for screws (500 kg/h) the source of the atmosphere methanol + propane

- Gas furnace for screws (700 kg/h) the source of the atmosphere, methanol

- Gas furnace for screws (800 kg/h) the source of the atmosphere methanol + propane

- Gas furnace screws (1000 kg/h) the source of the atmosphere, methanol

- Electric furnace for screws (1000 kg/h) the source of the atmosphere, methanol

- Electric furnace for screws (800 kg/h) the source of the atmosphere methanol + propane

- Conveyor belt inspection certificate

ONE WHOLE-SET OF CONTINUOUS BRIGHT CARBURIZING (HARDENING) QUENCHING FURNACE (BY GAS BURNER SYSTEM)

One whole-set of continuous bright carburizing (hardening) quenching furnace (by gas burner system), model RG, for heat treatment (hardening + carburizing and high tempering) of fasteners (allpurpose screws, nuts and special products) in protective atmosphere.

Features of hardening and tempering furnaces with gas heating:

- Used in fasteners industries, automobile, motorcycle, bicycle parts industries, chains industries, concrete nails industries, hand-tools industries, hardware industries, stationery industries, forging parts industries, aerospace industries and commercial heat-treatment industries, ect.

- The gas burner is made on the basis of US technology. Exhaust air is removed through the exhaust pipe. The special design of double pipe maintains a uniform temperature. 60% of the heat carried in the heat exchanger.

- The radiation tube is made of heat-resistant centrifugal cast pipe according to Japanese production technology with small deformation, and increased service life.

- Gas heating system saves energy costs.

- The heating process is much faster than when heated by electricity. The oven is ideal for mass production.

Technical Specification

| Model | Processing capacity | The width of the conveyor, mm | Inside furnace height, mm | Annealing chamber length, mm | Maximum combustion, kcal/hr | Maximum power, kW | |

|---|---|---|---|---|---|---|---|

| for the production of medium-high carbon steel, kg/hr | for the production of low carbon steel, kg/hr | ||||||

| RG-811-1 | 506-572 | 413-463 | 800 | 100 | 6000 | 180000 | 45 |

| RG-811-2 | 720-780 | 546-598 | 800 | 100 | 8000 | 300000 | 90 |

| RG-811-3 | 1000-1100 | 833-917 | 800 | 100 | 10000 | 450000 | 90 |

| RG-811-4 | 1800-1980 | 1499-1650 | 1200 | 100 | 12000 | 690000 | 135 |

General Description of the Conveyor Hardening-Quenching Unit

| The area occupied by the equipment | 51 m × 2,5 m = 127,5 m2 |

|---|---|

| Space requirements for equipment | 61 m × 6 m = 366 m2 |

| The processing time in the tempering furnace | 40 - 100 min |

| The density of products layout on the conveyor belt of tempering furnace | no more than 118 kg/m2 |

| Water temperature of the washing device | degreasing: 60-80 °C phosphate removal: 60-80 °C |

| The amount of residual product contamination after washing | no more than 0,3 kg per tonne |

| Temperature in the tempering furnace | 800-930°C |

| Temperature uniformity in the furnace chamber | ±6°C |

| Hardening furnace atmosphere | shielding gas - endogas; additional gas -propane + air |

| Maximum hardening oil temperature | 90°C |

| Temperature in the tempering furnace | 380-700°C |

| Temperature uniformity in the tempering furnace | ±6°C |

| Tempering furnace atmosphere | without protective atmosphere - air |

| Maximum temperature of the composition in the emulsion Cooling bath (bath anticorrosion treatment) | 50°С |

CONTINUOUS BRIGHT CARBURIZING QUENCHING FURNACE / WHOLE-SET EQUIPMENT FOR HEAT TREATMENT ELECTRIC HEATING TYPE

Electric heating type continuous bright carburizing quenching furnace applications: fasteners industries, automobile, motorcycle, bicycle parts industries, chains industries, concrete nails industries, hand-tools industries, hardware industries, stationery industries, forging parts industries, aerospace industries and commercial heat-treatment industries, etc.

Electric heating type continuous bright carburizing quenching furnace applications: fasteners industries, automobile, motorcycle, bicycle parts industries, chains industries, concrete nails industries, hand-tools industries, hardware industries, stationery industries, forging parts industries, aerospace industries and commercial heat-treatment industries, etc.

Brief Technical Specification

| Model | Treating Capacity to Middle or High Carbon Steel | Treating Capacity to Low Carbon Steel | Whole-set Total Power Output (kw) | Whole-set Power Used Middle Carbon 85% / Low Carbon 70% (kw) | Whole-set Total Length (mm) | ||

|---|---|---|---|---|---|---|---|

| kg/hr | tons/month | kg/hr | tons/month | ||||

| RG-805-A | 124-138 | 77-86 | 48-69 | 30-43 | 183-177 | 150/123 | 25495 |

| RG-805-1 | 198-220 | 123-138 | 84-120 | 52-75 | 218-203 | 173/142 | 27995 |

| RG-805-2 | 352-385 | 220-242 | 204-240 | 127-150 | 320-290 | 247/203 | 31495 |

| RG-805-3 | 414-483 | 259-299 | 313-350 | 195-218 | 393-353 | 300/247 | 31995 |

| RG-805-4 | 506-572 | 316-358 | 413-463 | 258-289 | 464-439 | 373/307 | 31995 |

| RG-805-5 | 720-780 | 450-486 | 546-598 | 341-373 | 543-513 | 436/359 | 35995 |

| RG-805-6 | 1000-1100 | 624-686 | 833-917 | 520-572 | 655-615 | 522/430 | 39430 |

| RG-805-6S | 1200-1320 | 749-824 | 999-1100 | 624-686 | 749-688 | 636/481 | 43430 |

| RG-805-7 | 1250-1375 | 780-858 | 1040-1146 | 649-715 | 759-683 | 645/478 | 39430 |

| RG-805-7S | 1500-1650 | 936-1030 | 1249-1375 | 779-858 | 886-797 | 753/558 | 43430 |

Furnaces for heat treatment. Completed projects

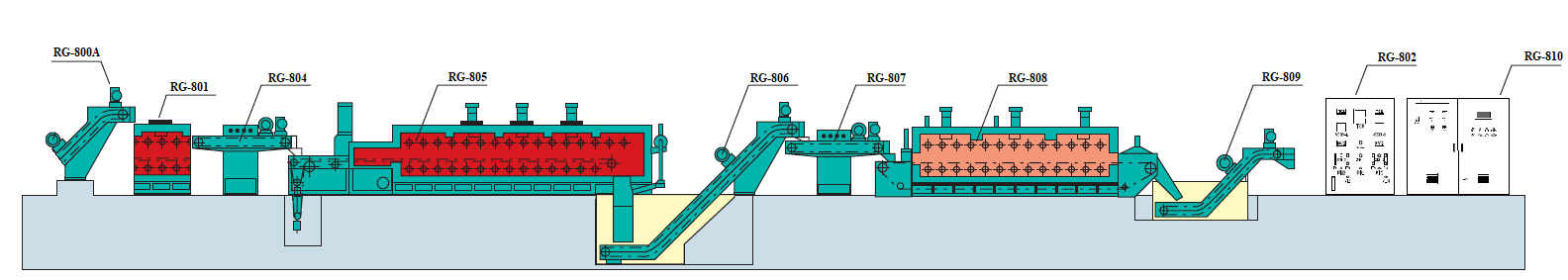

EQUIPMENT CONFIGURATION OF THE HARDENING AND TEMPERING LINE FOR HEAT TREATMENT

Conveyor hardening and tempering unit for heat treatment of fasteners, metal products and parts, as a rule, consists of ten components of the equipment.

| RG-800A | The mechanism of automatic supply by magnetic belt |

|---|---|

| RG-801 | Endothermic gas generator automatic temperature control panel |

| RG-804 | Front tank for cleaning and degreasing |

| RG-805/810A | Hardening furnace with continuous automatic temperature control panel |

| RG-806 | Tank for oil hardening |

| RG-807 | Back tank for cleaning and degreasing (flat type) |

| RG-808/810B | Continuous tempering furnace with hot blast (max. Temp. 650°C) / automatic temperature control panel |

| RG-809 | Tank for anticorrosion treatment (level two) |

| RG-802A | Two-channel automatic carbon control device (made in USA) (with solenoid valve) |

| RG-810C | Automatic Control Panel |

| RG-811 | Computer system |

| Spare parts | Operational parts, tools and accessories for 1 year operation of the unit. |

CONVEYOR-TYPE BLACKENING FURNACE

Equipment Application

- Widely used for blackening, continuous hardening of metal products, followed by tempering

Peculiarities of equipment:

- Environmental security.

- The heat treatment temperature should exceed 400°C.

- The best effect is achieved for the blackening of parts with uniform color and good anti-corrosive performance.

SPECIFICATIONS

| Model | Through capacity, kg/h | The width of the conveyor, mm | Inside furnace height, mm | Annealing chamber length, mm | Feed length, mm | Output volume, m3/h | Maximum power, kW |

|---|---|---|---|---|---|---|---|

| RG-814-1 | 750-850 | 1000 | 100 | 7000 | 2200 | 60 | 145 |

| RG-814-2 | 950-1050 | 1000 | 100 | 9000 | 2200 | 80 | 189 |

| RG-814-3 | 1150-1250 | 1000 | 100 | 11000 | 2200 | 80 | 252 |

| RG-814-4 | 2100-2400 | 1400 | 100 | 13000 | 2200 | 120 | 360 |