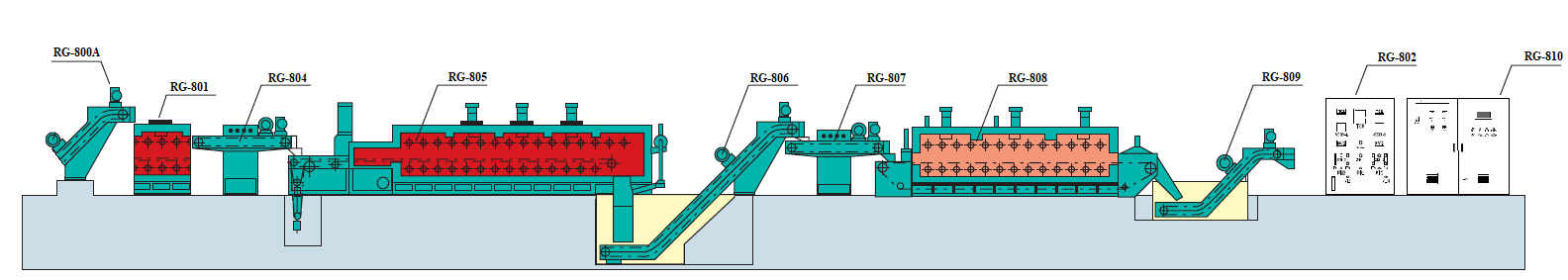

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

AUTOMATIC CARBON POTENTIAL CONTROL SYSTEM

Application & Features of Carbon Potential Control System

The equipment to control the carbon potential (C/P) of atmosphere for hardening furnace automatically.

The principle of operation is based on system of automatic recognition of O2 BARBER COLMAN carbon, error control ±0.03% (carbon). Manufacturing of the United States.

Carbon Potential Control System Equipment Composition

Automatic Carbon Potential Control System composed of:

- Oxygen probe

- Solenoid Valve

- Recording system (temperature, carbon, gas flow)

- Burning air standard piping for air combustion.

The equipment is available in the following versions: One-Point type RG-802A, Double-Point type RG-802B and Three-Point type RG-802C (RG802A + B)

Double-Spot type Automatic Carbon Potential Control System RG-802B O2

Double-Spot type Automatic Carbon Potential Control System manufactured in USA. One spot for RX Generator RG-801, second spot for Quenching Furnace RG-805.

| Width | 700 mm |

| Height | 1800 mm |

| Diameter | 700 mm |

| Power supply | 220-240В х 3 phase х 50-60 Hz |

- Carbon Potential Controller AC20 (made in USA): 2 pcs

- K-type oxygen sensor (made in USA): 2 pcs

- Air supply system: 1 unit

- Digital temperature display: 2 units

- Recorder: 1 set

Three-Spot type Automatic Carbon Potential Control System RG-802C O2

Three-Spot type Automatic Carbon Potential Control System with electromagnetic valve (two spots for control of Quenching Furnace RG-805 and one spot for control of RX Generator RG-801) model RG802A+B manufactured in USA.

Components

| 1 | C/P controller: Model: AC20 (SSI, made in USA) | 2 sets |

| 2 | Recorder:

| |

| 3 | Oxygen probe:

| |

| 4 | Air pump:

| |

| 5 | Voltage stabilizer: 110 V х 500 W | 1 комплект |

| 6 | MV meters | 2 sets |

| 7 | Temperature display | 2 sets |

| 8 | Flow meters:

|