LARGE METAL WIRE PACKAGING LINES

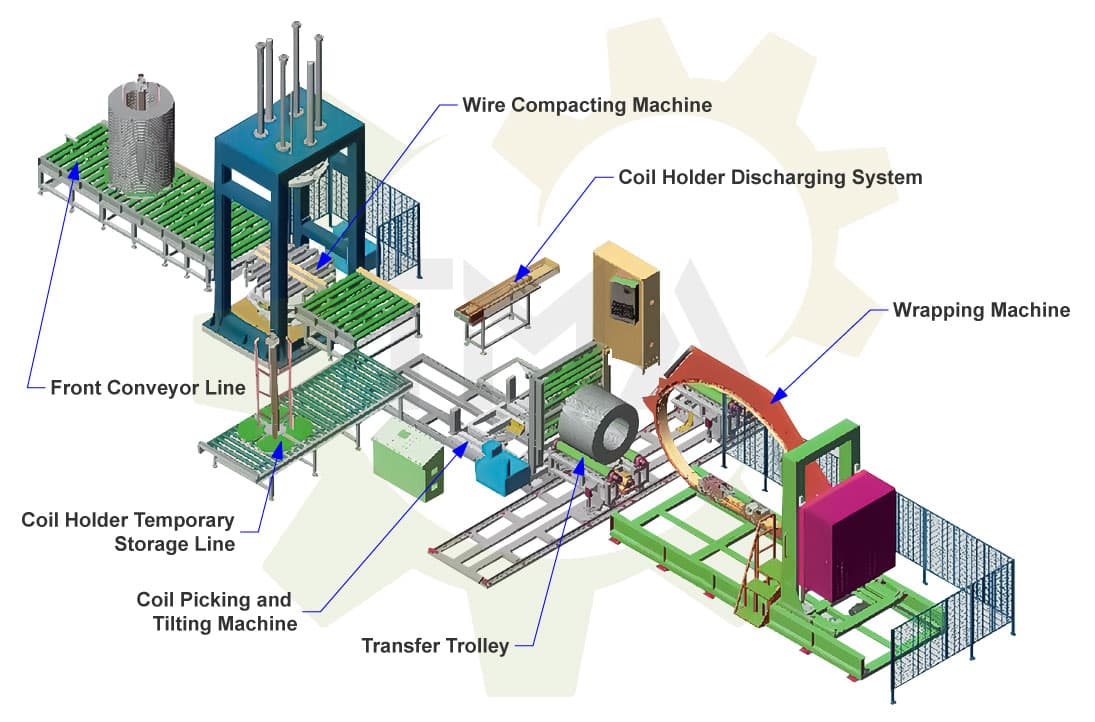

Wide wire coil compacting and holder-removing packing line

The packing line is designed for compacting, strapping, holder removal, and wrapping of large metal wire products. It is composed of a feeding conveyor, compacting and rotating system, strapping station, holder removal system, tilting system, wrapping machine, and other components.

| Application | Steel Wire |

| Wire Coil Inner Diameter | ≥405 mm |

| Wire Coil Outer Diameter | 800-1200 mm |

| Wire Coil Width | 600-1200 mm |

| Coil Weight | ≤2.5 T |

Horizontal Wire Coil packing Line

This packing line is suitable for packing various metal wire products. It includes a feeding line, weighing system, wrapping machine, labeling machine, storage system, and more.

| Application | various Wire Products |

| Wire Coil Inner Diameter | ≥600 mm |

| Wire Coil Outer Diameter | 1100-1500 mm |

| Wire Coil Height | 200-800 mm |

| Coil Weight | ≤2.5 T |

STEEL WIRE PACKING MACHINE

Steel Wire wrapping Machines

The SWM series steel wire packing machine is primarily used for wrapping various types of steel wire, stainless steel wire, galvanized wire, strand wire, and other wire coil products. This process ensures the product is relatively sealed, well-protected, and aesthetically pleasing.

Key features include:

- Choice of vertical or horizontal type according to needs.

- Option for automatic or semi-automatic control.

- Selection of different wrapping material release systems.

- Adjustable turning ring height to accommodate objects with different inner and outer diameters. Precise positioning to protect the ring effectively.

- High antifriction PU for friction wheels and a fully cast structure for the turning ring.

- Synchronous wrapping system option for wrapping two different materials simultaneously.

- Compatibility with various packing materials such as knit tape, stretch film, non-woven fabrics, bubble film, plastic tape, compound paper, and hessian.

- Patented tension control system, allowing adjustment of wrapping tension and overlap as needed. Wrapping with constant tension, suitable for a wide range of applications.

- Supportive and protective rollers that can be wrapped with PU if required.

- Button operation for convenience and efficiency.

- Easy wrapping tape replacement with one-button reset.

| Model | SWM-S200 | SWM-S300 | SWM-S500 | SWM-W150 | SWM-W200 | SWM-W600 | SWM-W1500 | SWM-T1200 |

|---|---|---|---|---|---|---|---|---|

| Wire Coil Outer Diameter, mm | 350-600 | 800-1200 | 600-1200 | 400-600 | 600-900 | 800-1500 | 1500-2500 | 800-1500 |

| Wire Coil Inner Diameter, mm | ≥200 | ≥400 | ≥400 | ≥200 | ≥400 | ≥600 | ≥1000 | ≥400 |

| Wire Coil Height (Width), mm | ≤200 | ≤300 | ≤500 | ≤100 | ≤200 | ≤600 | ≤300 | 800-1500 |

| Wire Skein Weight, kg | ≤50 | ≤200 | ≤1000 | ≤80 | ≤100 | ≤1500 | ≤1500 | ≤2000 |

| Ring Speed | ~ 100 r/min | ~ 80 r/min | ~ 80 r/min | ~ 80 r/min | ~ 70 r/min | ~ 60 r/min | ~ 80 r/min | ~ 2 m/sec |

| Packing Material | knit tape/ composite paper tape / laminated inhibited paper tape / woven tape / non-woven fabrics / stretch film / bubble film / anti-corrosion film / hessian / etc. | |||||||

| Power Output, kW | ~ 1.0 | ~ 3.0 | ~ 4.5 | ~ 3.0 | ~ 3.0 | ~ 10.0 | ~ 4.5 | ~ 12.0 |

| Power Supply | 380VAC 50Hz 3 Phase | |||||||

| Pushing-out device (for easy offloading) | optional | / | ||||||

| Synchronous Wrapping | optional | / | optional | / | ||||

| Moveable Wrapper | / | optional | / | |||||

| Circumferential labeling device | optional | |||||||