CLEANING AND DERUSTING AGENTS

We are ready to offer high performance cleaning products, developed according to the technology, corresponding to the standards for the environment protection and the requirements of non-waste production, including wastewater treatment facilities increased detergency as well as inhibitors and metal corrosion processes inhibitors.

Neutral degreasing agent, degreaser AQ-CLEAN RU series

Neutral degreaser AQ-CLEAN RU SERIES is suitable for cleaning electronic parts and components after main treatment. Ideal for degreasing and cleaning lightly soiled parts made of steel; for washing colored metals, copper and copper alloys items.

| Name | Characteristics | Reccomended operation conditions | Material | Package | |||||

| blast cleaning | ultrasonic cleaning | temperature, ℃ | concentration | iron | aluminium | cooper | |||

| RU-1040N | neutral liquid pH 7.2 (1%) | X | O | 50-60 | 0.2-2 | O | O | 18L 200L | |

| Standard nonionic detergent with neutral environment | |||||||||

| RU-1040NX | neutral liquid pH 8.3 (1%) | X | O | 50-60 | 0.2-2 | O | O | 18L 200L | |

| Neutral clearer based on RU-1040N with corrosion ptotection | |||||||||

| RU-1040NP-3 | neutral liquid pH 8.3 (1%) | X | O | 50-60 | 0.2-2 | O | X | 18L 200L | |

| Neutral clearer based on RU-1040N with additives for cooper protection from decoloration | |||||||||

| RU-1042C | neutral liquid pH 7.3 (1%) | X | O | 50-60 | 0.2-2 | O | O | 18L 200L | |

| Standard nonionic detergent with neutral environment with anticorrosion additives for clearing cooper and aluminium products | |||||||||

Alkaline degreasing agent, degreaser AQ-CLEAN RS series

AQ-CLEAN RS SERIES alkaline degreaser is appropriate for cleaning products by solution dip for ultrasonic cleaning. Ideal for degreasing weak and heavily soiled parts treated at grinding, polishing and lapping machines. Material: aluminium and cooper; iron and castings. Alkaline degreaser has a low degree of foaming.

| Name | Characteristics | Reccomended operation conditions | Material | Package | |||||

| blast cleaning | ultrasonic cleaning | temperature, ℃ | concentration | iron | aluminium | cooper | |||

| RS-200T | alkaline powder pH 12.6 (1%) | X | O | 50-60 | 1-5 | O | O | O | 20kg box |

| Strong degreaser for clearing ferrous and colored metals | |||||||||

| RS-200EW | alkaline powder pH 12.6 (1%) | O | 50-60 | 1-5 | O | O | O | 20 kg box | |

| Alkaline degreaser is surface active agent (SAA) based on S-200T and is ideal for sluggish oil removal used in drawing | |||||||||

| RS-400 | high-concentrated alkaline solution pH 13.0 (1%) | X | O | 50-60 | 1-5 | O | X | 20kg box | |

| Ideal for sluggish oil removal used in drawing and machining. It contains high concentration of caustic soda. Not dangerous. | |||||||||

| RS-420 | high-concentrated alkaline solution pH 13.3 (1%) | X | O | 50-60 | 1-5 | O | X | X | 20kg box |

| Ideal for sluggish oil removal used in drawing, machining, grinding, polishing and adaptation equipment. It contains high concentration of caustic soda. Not dangerous. | |||||||||

| RS-200TL | alkaline solution pH 10.8 (1%) | X | O | 50-60 | 1-10 | O | O | O | 18L 200L |

| Alkaline solution based on S-200T | |||||||||

| RS-200EWL | alkaline solution pH 10.8 (1%) | O | 50-60 | 1-10 | O | O | O | 18L 200L | |

| Alkaline solution based on S-200T | |||||||||

Cleaning agent with derusting ability

Cleaning agent with derusting ability AQ-CLEAN RSP series

Foamless spray for cleaning of ferrous and colored metals (copper, aluminum, etc.), protects against corrosion. Used in baths with barbotage under blasting pressure and high-speed vibration clearing. Suitable for cleaning products by solution dip for ultrasonic cleaning, does not require rinsing.

| Name | Characteristics | Reccomended operation conditions | Material | Package | |||||

| blast cleaning | ultrasonic cleaning | temperature, ℃ | concentration | iron | aluminium | cooper | |||

| RSP-160 | neutral liquid pH 7.8 (1%) | О | O | 50-60 | 1-5 | O | O | 18L 200L | |

| Cleaning agent with neutral environment consists of organic components, no inorganic salt. Doesn't require rinsing. | |||||||||

| RSP-160C | neutral liquid pH 7.8 (1%) | О | O | 50-60 | 1-5 | O | О | O | 18L 200L |

| Cleaning agent with neutral environment based on SP-160 with corrosion inhibitor and improved formula of corrosion protection. In contains components slowing corrosion process. Doesn't require rinsing. | |||||||||

| RSP-200C | weakly alkaline solution pH 11.3 (1%) | О | O | 50-60 | 1-5 | O | О | О | 18L 200L |

| Cleaning spray based on inorganic alcalines. It is applicable for cleaning under the pressure, foamless. In contains components slowing corrosion process. Doesn't require rinsing. | |||||||||

| RSP-281C | weakly alkaline solution pH 11.4 (1%) | О | O | 50-60 | 1-5 | O | О | O | 18L 200L |

| Improved variant of cleaning spray SP280C, with additives preventing intensive foam formation. | |||||||||

Cleaning agent with derusting ability AQ-SUPER CLEAN series

Suitable for cleaning ferrous metals, pig iron parts by solution dip for ultrasonic cleaning and blasting under pressure. The tool is both a corrosion inhibitor and a cleaner. It removes scale and foreign bodies from the surface of parts.

Special features, Types and Characteristics

- Degreaser with neutral environment.

- Degreaser with alkaline environment.

- Foamless.

- Does not require rinsing.

- Does not contain phosphorus.

- For degreasing aluminum and aluminium alloys.

- Degreaser with a weakly alkaline environment.

- Applicable for casting and pig iron blanks.

- Degreaser with low degree of chemical oxygen demand (COD).

Oil and water separation efficiency

After addition of mineral oil (5%) to aqueous solution (50 ℃) with a degreaser (2%), ultrasonic waves are impacted into the solution for 30 minutes. And then the solution was left for 1 hour.

RC-201A

company

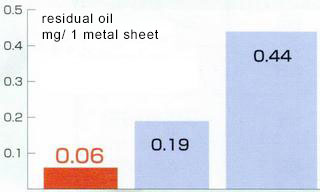

Washing capacity comparison table

Comparison of degreaser’s anticorrosion properties

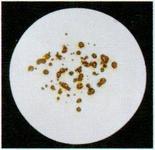

After dipping in a solution pig iron particles were treated by porous paper for filtering and left for 24 hours. At the end particles surface inspection for corrosion was carried out.

| Degreaser concentration 1 % | Degreaser concentration 2% | |

| AQ-SUPER CLEAN RC-300 |  |  |

| Degreaser of another company |  |  |

Clearing process conditions

- Ultrasonic cleaning (3% aqueuos solution, temperature 60℃, clearing time – 1 minute).

- Rinsing with purified water at ambient temperature, time – 1 minute.

- Drying with hot air at a temperature of 120℃, time – 10 minutes.

AQ-SUPER CLEAN SERIES

| Name | Characteristics | Reccomended operation conditions | Material | Resistance to corrosion (24 hours) | Package | |||||

| blast cleaning | ultrasonic cleaning | temperature, ℃ | concentration | iron | aluminium | cooper | ||||

| RC-200 | weakly alkaline solution pH 8.7 (1%) | O | O | ambient temperature-60 | 1-2 | O | O | O | 3% no corrosion | 18L 200L |

| Agent based on C-200 with improved washing and degreasing characteristics. | ||||||||||

| RC-201 | weakly alkaline solution pH 8.7 (1%) | O | O | ambient temperature-60 | 1-2 | O | O | O | 3% no corrosion | 18 L 200L |

| Agent based on C-200 with improved washing and degreasing characteristics. | ||||||||||

| RC0201A | weakly alkaline solution pH 8.8 (1%) | O | O | ambient temperature-60 | 1-2 | O | 3% no corrosion | 18L 200L | ||

| Agent with improved degreasing characteristics and oil from water separation abilities. This affect can be achieved by adding some alkaline sault to С-200. | ||||||||||

| RC-300 | weakly alkaline solution pH 8.6 (1%) | O | O | ambient temperature-60 | 1-2 | O | O | O | 2% no corrosion | 18L 200L |

| Degreaser with low foam forming ability and high corrosion protection characteristics of pig iron parts. | ||||||||||

| RC-400 | weakly alkaline solution pH 9.8 (1%) | O | O | ambient temperature-60 | 1-2 | O | 4% no corrosion | 18L 200L | ||

| Degreaser with low foam forming ability and high corrosion protection characteristics of ferrous metal parts. | ||||||||||

| RC-500 | weakly alkaline solution pH 10.5 (1%) | O | O | ambient temperature-60 | 1-2 | O | X | X | 5% no corrosion | 18L 200L |

| Degreaser with low foam forming ability and high corrosion protection characteristics of ferrous metal parts and pig iron blanks. | ||||||||||

Special purpose alkaline cleaning agent

Special purpose alkaline cleaning agent is widely used for oil removal from industrial mechanisms of enclosed type operating at high pressure, for thermal scale removal, etch solutions and for removing covering oil films. It removes corrosion.

| Name | Characteristics | Reccomended operation conditions | Material | Package | |||||

| blast cleaning | ultrasonic cleaning | temperature, ℃ | concentration | iron | aluminium | cooper | |||

| RS-500 | high-concentrated alkaline solution pH 13.3 (1%) | X | O | 50-60 | 1-5 | O | Х | Х | 20kg box |

| Ideal for cleaning parts treated at the grinding and polishing and lapping machines for descaling, removing the oil used in drawing equipment, emulsions for cooling and lubrication of the cutting tools. High-concentrated alkaline solution contains caustic soda. It is classified as toxic and dangerous substance. | |||||||||

| RG-50L | high-concentrated alkaline solution pH 14.0 sheer | X | O | ambient temperature-60 | sheer | O | Х | Х | 18L |

| Alkaline rust-removing agent. Ideal for thermal scale and covering oil films removal. | |||||||||

| RG-60L | high-concentrated alkaline solution pH 14.0 sheer | X | O | ambient temperature-60 | sheer | O | Х | Х | 18L |

| Alkaline rust-removing agent. Ideal for thermal scale and covering oil films removal. | |||||||||

| RE-200 | alkaline solution pH 12.6 (1%) | X | O | ambient temperature-60 | 1-10 | O | X | X | 18L |

| Used to etch aluminium degreasing, etch depth from several microns to 30 microns. Removes iron turnings and heat scale. | |||||||||

| RE-200F | alkaline solution pH 12.6 (1%) | O | O | ambient temperature-60 | 1-10 | O | Х | Х | 18L |

| Used to etch aluminium degreasing, etch depth from several microns to 30 microns. Removes iron turnings and heat scale. | |||||||||

Water-soluble corrosion inhibitor AQ-UNRUSTER series

Suitable for parts cleaning by solution dip and blast cleaning under pressure. Safe for the environment, water soluble, waterblocking, foamless, free of amines. Widely used for the processing of parts made of iron, cast sections, copper, copper alloys, aluminum and aluminium alloys.

Special features, Types and Characteristics:

- Foamless.

- Waterblocking.

- With low degree of chemical oxygen demand (COD).

- With dewatering ability.

- No spots and sediment.

- Free of amines.

| Type | Name | Material | Application methods | concentration | Properties (1% aqueuos solution) | Operation Characteristics | Package |

| Foamless | RC-100 | cooper, aluminium, iron, cast sections | immersion cleaning, blast cleaning under mean or high pressure | 2-4% | pH 8.4 | pig iron, 24 hours, no corrosion (3% aqueuos solution) | 18L 200L |

| RC-150 | iron, cast sections | immersion cleaning, blast cleaning under mean or high pressure | 1-3% | pH 11.6 | pig iron, 24 hours, no corrosion (3% aqueuos solution) | 18L 200L | |

| Almost foamless | RC-200 | iron, cast sections | immersion cleaning, blast cleaning under mean or high pressure | 1-2% | pH 8.7 | pig iron, 24 hours, no corrosion (2% aqueuos solution) | 18L 200L |

| RC-155 | iron, cast sections | blast cleaning under mean or high pressure | 1-2% | pH 11.7 | pig iron, 24 hours, no corrosion (2% aqueuos solution) | 18L 200L | |

| Non-staining | RC-600C | ferrous metal, treated sheet metal | immersion cleaning, blast cleaning under low pressure | 3-4% | pH 7.7 | iron, nickel alloy, no corrosion (50℃, 95%, 24h) | 18L 200L |

| Free of amines | RC-660 | iron, ferrous metal | immersion cleaning | 3-4% | pH 8.2 | pig iron, 24 hours, no corrosion (2% aqueuos solution) | 18L 200L |

| Waterblocking | RC-700 | iron, cast sections, aluminium, aluminium alloys | by the addition to stope for clearing in neutral or alcaline environment | 0.5-1% | pH 9.5 | pig iron, 24 hours, no corrosion (3% aqueuos solution) | 18L 200L |

| With low degree of chemical oxygen demand (COD) | RC-770 | iron, ferrous metal | COD: 5 parts per million (Mangan) COD: 100 parts per million (Chrome) | 2-3% | pH 11.0 | Electromagnetic sheet metal, indoor examination throughout 7 days, 25℃ | 18L 200L |