BARREL/CHUCK TYPE SURFACE TREATMENT EQUIPMENT

LINE FOR GALVANIZING AND PHOSPHATIZING FASTENERS OF DRUM TYPE

Equipment with galvanic drums used for plating of various thicknesses on parts of various sizes and shapes.

It is widely used for surface treatment of metal fasteners (screws, nuts, bolts, etc.), Parts, hardware, electronics, lightning, parts of cars, motorcycles, light fixtures, furniture accessories, etc.

Surface treatment is carried out inside the drum by sequential rotation of the blank.

The line of equipment includes pre-processing, galvanization, post-processing. Galvanic equipment of drum-type supports black and gray phosphating.

Features

- Galvanic drums have high load capacity, ensure a long service life of the equipment. High quality electroplating and performance are achieved due to the continuous rotation of galvanic drums. The design of the lid prevents galvanic drum hit chemicals in the other line units. All copper conductors insulated and have gone through the process of anti-corrosion treatment. In case of malfunction they are easy to replace.

- Loading and unloading of products is controlled hydraulically, which in turn reduces labor costs. There are mechanical arrows aimed at simplifying the operation and management of equipment. Features of the arrow structure: safety and low noise levels, the use of the sensor to prevent the transfer abroad of the drum mechanism; suspension arm can move up and down, performing the drip function. In the event of a power failure, the arrow goes into manual mode, thereby preventing the processing of defective products.

- The automatic control system of galvanic line autooperator provides a continuous surface treatment process, including the possibility of changing and adjusting the workflow as needed. In addition, the graphical management options are available on an industrial computer with system software.

- The design of the equipment is based on the principles of quality, safety, stability. The galvanic bath is made of high-quality polypropelene. It is used for electroplating of small parts, it is characterized by high precision and uniformity of the coating. The equipment is fairly compact and does not take much working space.

Technical description and specification of the equipment

Galvanizing line baths

| Hot degreasing baths | 850Lx1590Wx750H | Baths material Cold washing baths, etching, electrolysis, nitric acid, neutralization galvanizing, exchange baths are made of chromate polypropelene in Germany, 12 mm thick. Hot degreasing baths are made of stainless steel SUS304 * 3t |

|---|---|---|

| Baths for rinsing in cold water | 650Lx1590Wx750H | |

| Etching baths | 850Lx1590Wx750H | |

| Nitric acid baths | 650Lx1590Wx750H | |

| Electrolysis baths | 800Lx1590Wx750H | |

| Neutralization baths | 650Lx1590Wx750H | |

| Galvanizing bath | 800Lx1590Wx800H | |

| White chrome Cr3 + chromating baths | 850Lx1590Wx750H | |

| Yellow chrome Cr3 +chromating baths | 850Lx1590Wx750H | |

| Hot water washing baths | 650Lx1590Wx750H | |

| Exchange baths | 650Lx1590Wx750H |

Description of baths manufacturing

The working surface is made of polypropylene. The conductive portion of the V-shaped copper. Bending plates of polypropelene made by an automatic bending machine.Welding and tie of baths parts are carried out using extrusion welding gun. Reinforcement made of polypropylene plate of 20 mm thickness. The side surface of baths made of steel SUS304. The metal structure to support the bath is made of U-shaped steel SUS304 3 " with polypropylene coating. Reinforced base of the bottom of the tank is made of U-shape steel SUS304 3". Baths are equipped with gear for 70 types of speeds, axle of steel SUS304 for transmission, drive motor of 3 hp, 2 hp and inverter of 3 hp

Distribution of copper conductors

Electrolysis baths: copper plates 10t × 80V. Coupling copper plate anode 10t × 100B. Copper rod diameter of 1 1/4 "Galvanizing Baths: copper plate 10t × 100V. Connecting copper plate of kathode 10t × 100V. Connecting copper plate of anode 10t × 100V. The copper rod 1/4". PP coating for copper rods. Titanium baskets 1310D * 105SH * 400V. Copper hook for fixation of zinc ingots 3/8 ".

Distribution of plumbing pipes

Water supply: the basic PVC pipe 2 ". Socket PVC 3/4". Yield: main PVC pipe 5. "Socket PVC 2". Note: The pipes are available relating to the distribution of equipment, pipes extending beyond the connection points of the line are installed by the customer.

Frame construction and rail equipment

Structure pillars are vertical and horizontal of quadrangular pillar of steel SS304, 80 x 80. crane rails made of stainless steel SUS304 quadrangular 80 * 80 coated plates of L-shaped steel SUS304 SUS304 * 4t L.

Working platform

The standard size of the working platform 750SH * 900V * 22900D. The material and method of manufacture: the main frame is made of L-shaped steel SUS304 40 * 40 *. The legs are made of quadrangular steel SUS304 38 * 38 *. The path for walking is covered with polypropylene plate of blue color.

Crane of rail type

Material of crane - steel grade SUS304 3.0 ~ 6.0t. Brake engine for moving up and down - 2 hp Brake engine for moving left or right - 1 hp Drum rotation brake engine 1/4 hp The speed of the crane forward / backward movement is controlled by a programmable logic controller. Position Sensors monitor the movement of cranes left and right, up and down at three speeds (regular, slow, anti-corrosive treatment modes). Cranes move on wheels made of polyurethane and are equipped with side wheels of polypropylene to maintain balance while moving forward / backward. Engines and gears are protected by caps made of PVC. On the crane is installed manual operating mechanism. Device with absolute measurement of coordinates helps determine the position of the crane.

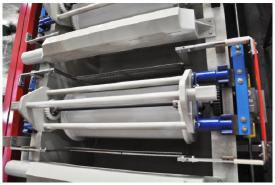

Specification of galvanic drums

Dimensions: 450φ * 1200m / ml. * Hole diameter of 4 mm, round form holes for bolts and nuts 450φ * 1200m / ml. * Hole diameter of 1.5-3 mm oblong holes for the screws. Drum Material: white slab of polypropylene 12mm thickness, made in Germany. Method of electricity wiring: a steel rod in the middle of the drum. The recommended weight per load is 150kg / drum. The equipment includes 3 sets of spare reels.

Specification of microcomputer control system

The control system controls the operation of two cranes. Each valve is controlled by a programmable logic controller made in Japan. The cranes are equipped with photocells to prevent lining each other drums. Horizontal counter of upper and lower limits of the crane is controlled by a touch switch. In the control system of the cranes route high class flat wire is used. Import inverter controls the speed of the crane up - down, left and right movement as well as the speed of rotation of the drums. Galvanizing mode is set on the touch screen control system.The control panel is available for adjustment function of the current rectifiers galvanizing baths, electrolysis and the control mode automatic addition of chemicals and the level of PH.

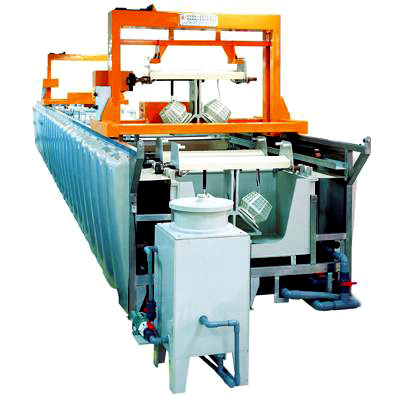

CHROMATING PASSIVATION LINE FOR FASTENERS WITH CLAMPING MECHANISM

Electrical equipment with clamping transport mechanism used to apply different types of galvanic coatings (zinc, nickel, silver, etc.) to the small details, to cover products in white, yellow, green or black. Specifically designed mechanism for passivation and painting of parts difficult to process. With it achieved uniformity of the painted surface, and optimum surface protection products from possible scratches.

The principle of operation of chromating and passivation line is sequential immersion tubs with perforated parts in the electrolyte, which is constantly in the bath. Movement of the bucket with the details is performed by means of a clamping mechanism capable of moving forward / backward, up / down, rotate clockwise / counterclockwise and mix parts tilted 45 degrees. The presence of the holes reduces the loss of electrolyte. The line of equipment is fully compatible with automatic movement of drying the finished product in a centrifuge with simultaneous supply of hot air and automatic unloading of finished products of pneumatic type. The entire production process is controlled by a computer system software, enabling mass production of high-quality galvanic coatings.

Technical description and specification of the equipment

Baths of chromating and passivation line

| Baths for rinsing in cold water | 1100Lx1100Wx1100H | Baths material Chromating and passivation baths line is made of polypropylene, manufactured in Germany, 12 mm thick. Manufacturer's Description |

| Phosphatizing Baths | 1100Lx1100Wx1100H | |

| Chromating baths Cr3 + (Black) | 2100Lx1100Wx1100H | |

| Fixing baths | 2100Lx1100Wx1100H |

Distribution of plumbing pipes

Water supply: the basic PVC pipe 2 ". Socket PVC 3/4". Yield: main PVC pipe 5. "Socket PVC 2". Note: The pipes are available relating to the distribution of equipment, pipes extending beyond the connection points of the line are installed by the customer.

Frame construction and rail equipment

Horizontal and vertical crossbars made of steel SS400 100 * 100 H-type. Crane rails made of steel SS400 100 * 100 H-type. Rail coating of L-type steel SUS304 * 4t.

Construction of clamping type crane

Material of the crane: the valve body is made of thick steel SS400 3.0t ~ 6.0t, with the shot peening. Power of the brake motor of reduction type for movement up and down is 3 hp, engine brake for reducing the type of movement from left to right - 1 hp rotary engine -1 hp motor with a clamping crown teeth -1 / 4 hp Passivation by rotating and dipping tap into the electrolyte. Cranes moving on wheels are made of polyurethane and are equipped with side wheels of polypropylene to maintain balance while moving forward / backward. Engines and gears are protected by caps made of PVC. On the crane manual operating mechanism is installed. Device with absolute measurement of coordinates helps determine the position of the crane. The space between the baths is closed with tray assembly for electrolyte.

Specification of microcomputer control system

Each valve is controlled by a programmable logic controller made in Japan. The cranes are equipped with photocells to prevent lining each other drums. Horizontal counter of upper and lower limits of the crane is controlled by a touch switch. In the control system of the cranes route high class flat wire is used. Import inverter controls the speed of the crane up - down, left and right movement as well as the speed of rotation of the drums.

GALVANIZING LINE FOR MICROELECTRONICS FASTENERS

Features

The automatic control system of galvanic line autooperator is made on the basis of an industrial computer with software system including a reporting system, warning indicator of malnutrition, the system of password protection.

Equipment Application

Equipment for plating with octagonal drums is widely used for surface processing of precision electronics, such as capacitors, connectors (terminals), semiconductors, microchips, etc.

Octagonal galvanic drums have a completely new design made of polypropylene. The equipment is completed with two octagonal drum tanks that have a high degree of impact resistance.

The patented design of the octagonal body has advantages in a smooth motion, stable, electricity, waste-free processing, large production capacity and ensuring the quality of the coating.