EQUIPMENT FOR GALVANIZING HARDWARE

ROBOTIC HOT-DIP GALVANIZING MACHINERY FOR HARDWARE

The design capacity of this automatic hardware hot-dip galvanizing line is 2400 ~ 4800 tons / year. The main types of work pieces are standard metal products in sizes M8-M20.

The design of the hot-dip galvanizing line is environmentally friendly and was originally designed to respect the environment. The equipment is modern, has a high level of energy saving, is easy to maintain and requires very few maintenance personnel.

The main parameters of the production line for hot-dip galvanizing of hardware

| Estimated annual productivity | 2400 ~ 4800 tons (* see the Performance Table) |

| Hourly productivity | 1 ton per hour (at the request of the customer can be increased to 2.5 tons |

| Production rate | feeding rate of 10 kg of metalware per minute (on customer's request can be increased to 20 ~ 25 kg / 45 seconds. It is possible to adjust the fastener feed rate and the weight of the fasteners in the basket through the PLC, to achieve the desired performance). |

| Type of galvanizing line | automatic, with manipulator (industrial robot) |

| Galvanizing bath heating | electric, with internal ceramic heaters |

| Galvanizing bath dimensions | 4,0 m × 1,2 m × 1,6 m |

| Zinc weight | 48 tons |

| Hot-dip galvanized bath material | the inner coating of the galvanizing bath is made of ceramic material with a service life of more than 10 years, and the heating element is silicon nitride ceramic. |

| Production line layout | linear or L-shaped (depending on the workshop) |

| Production line personnel by operations | preparation and loading - 1 person, preliminary processing - 1 person, galvanizing (only control) - 1 person, inspection, adjustment - 1-2 person |

| Production line schedule | 300 days a year in one or two production shifts |

| Production rate (feed rate of metalware) | Productivity per hour | Number of working days per year | Estimated annual productivity | |

|---|---|---|---|---|

| 1 shift / day | 2 shifts / day | |||

| 10 kg / min | 600 kg / hour | 300 days | 1440 t | 2880 t |

| 12.5 kg / min | 1 t / час | 2400 т | 4800 т | |

| 25 kg / 45 sec | 2 t / hour | 4800 t | 9600 t | |

| 31.25 kg / 45 sec | 2.5 t / hour | 6000 t | 12000 t | |

Parameters of the utility networks of the production line

| Total power consumption | 800 kVA |

| Supply voltage | 380/220V±10% |

| Water supply | water pressure not less than 0.2 MPa, DN100/DN60 |

| Compressed air supply | 10 m³/min, compressed air pressure 0.6 MPa ~ 0.8 MPa, DN25/DN40 |

Hot-Dip Galvanizing Line Automation

Operations requiring operator presence:

- loading of metal products;

- zinc coating quality inspection;

- maintenance of the production line;

- repair of equipment.

Automatically performed operations:

- etching and rust removal;

- rinsing with water;

- fluxing;

- drying;

- weighing and loading into the hot dip galvanizing bath;

- hot-dip galvanizing;

- cooling in water;

- passivation.

HOT GALVANIZING PRODUCTION PROCESS

This equipment can operate both according to the traditional technological process of hot-dip galvanizing and according to the new environmentally friendly process with the utmost respect for the environment.

The production process of hot-dip galvanizing of hardware with traditional technology

Surface preparation

Alkaline rinsing and degreasing

Rinsing in water

Pickling and rust removal

Rinsing in water

Fluxing

Drying

Hot dip galvanizing

Centrifugation

Passivation

Cooling in water

Coating quality inspection

Packaging

- At the discretion of the buyer, the stages of alkaline rinsing / degreasing and rinsing with water (before hot-dip galvanizing) can be excluded if there are no heavy contaminants on the processed hardware and only traces of mineral oils are present. In this case, you can use a more environmentally friendly process of simultaneous degreasing and pickling in an acidic solution. Solutions for performing these operations contain both pickling and degreasing components and corrosion inhibitors of metals in this environment. This will not affect the quality of the hot dip galvanized.

- At the discretion of the purchaser, the alkaline rinsing / degreasing and water rinsing steps (before hot-dip galvanizing) can be replaced by shot blasting to remove oil stains from the surface. This will not affect the quality of the hot dip galvanized.

- The aforementioned serves mainly to reduce the amount of waste water in the case of slight contamination of the surface of the hardware.

The environmentally friendly hot-dip galvanizing production process of hardware

Surface preparation

Surface Shot Blasting

Ultrasonic cleaning

Rinsing in water

Fluxing

Drying

Hot dip galvanized

Centrifugation

Passivation

Cooling in water

Coating quality inspection

Packaging

- Such a technological process increases the level of environmental protection by eliminating the processing of hardware with alkali, acid, and subsequent rinsing with water.

- The low consumption of rinsing water used in ultrasonic cleaning can be further reduced by 30% due to its cleaning and reuse.

Features of the production process using traditional technology

- The workpieces are transported by gantry lifter to the alkaline washing bath (temperature 35~45°C) to remove oil and other impurities from the surface of the workpieces with warm alkali. When cleaning is complete, the drum is raised and rotated over the reservoir, the alkaline liquid carried by the parts drains back into the reservoir. This step in the process can be replaced by shot blasting.

- After alkaline rinsing, the workpiece is transported by a gantry carriage controlled by the PLC to the water rinsing bath to remove alkaline solution, emulsion and other residual products from the surface of the workpieces in order to prevent these contaminants from entering the process tank.

- A gantry lifter, controlled by a PLC, transports the drum to a hydrochloric acid bath with acid concentrations of 16-18%. Since oxides of different composition and structure, rust, scale, iron shavings can appear on the surface of steel products, etching in hydrochloric acid is recommended. The best cleaning is achieved by rotating the drum, in which the parts to be cleaned collide with each other. After etching is complete, the drum is lifted and rotated over the acid reservoir so that acid residues from the parts drain into the reservoir. Next, the gantry lifter moves the drum to the water rinsing bath in order to wash off the remains of the process solution and salts from the metal surface.

- Then the drum with the workpiece is moved to the fluxing bath with a liquid temperature of 60 ~ 70°C. Fluxing completes the preparation of the surface for galvanizing. A thin layer of a mixture of 25% ammonium chloride and 25% zinc chloride remains on the parts. The protective film does not allow air to pass through and prevents oxidation of the workpiece during galvanizing and provides strong adhesion to zinc. The above process is mainly intended for cleaning workpieces in order to reduce zinc consumption by improving the wettability of the treated surface with molten zinc when immersed (by reducing the surface tension of the zinc melt).

- Drying completes the preparation for hot-dip galvanizing. It is used to prevent splashing of zinc by water vapor during immersion in the furnace and deformation of parts. If the remaining moisture is not removed, then when lowered into the bath, it will instantly evaporate, forming something like microexplosions (splashes) and creating bubbles on the parts. As a result, the entire surface will be covered with round dark spots, where zinc has not adhered.

- Then the workpieces are transferred to the hot-dip galvanizing bath. This automatic hot-dip galvanized ceramic bath consists of a body, ceramic inner heating tube and an electrical temperature control system. The corrosion-resistant thermocouple is in direct contact with the liquid zinc to ensure a stable temperature of the liquid zinc (temperature difference within ±2°C).

- Next, the zinc-coated blanks are transported to a centrifuge to remove excess zinc from the surface.

- From the centrifuge, zinc-coated metal products are automatically transported to the passivation bath to give the zinc coating an attractive decorative look and improve the quality of the zinc coating. After passivation, the hardware is transported to a bath with water for rapid cooling and stabilization of the strength of the zinc layer on the surface of the workpiece.

- Then, the cooled hardware is removed from the water cooling bath by a conveyor belt and transferred to a collecting device or conveyor for further transfer to the inspection and packaging area.

Main equipment of the production line

1. Production line foundation

In accordance with the dimensions of the pretreatment tank, a cement step with a height of 200 mm is built at ground level, and around it, at a distance of 300 mm from the step, a fence with a height of 250 mm is built, and a gutter of 300 x 300 mm is made in the ground into the emergency tank.

The entire foundation is covered with glass fiber reinforced plastic (FRP) as a leakage protection layer.

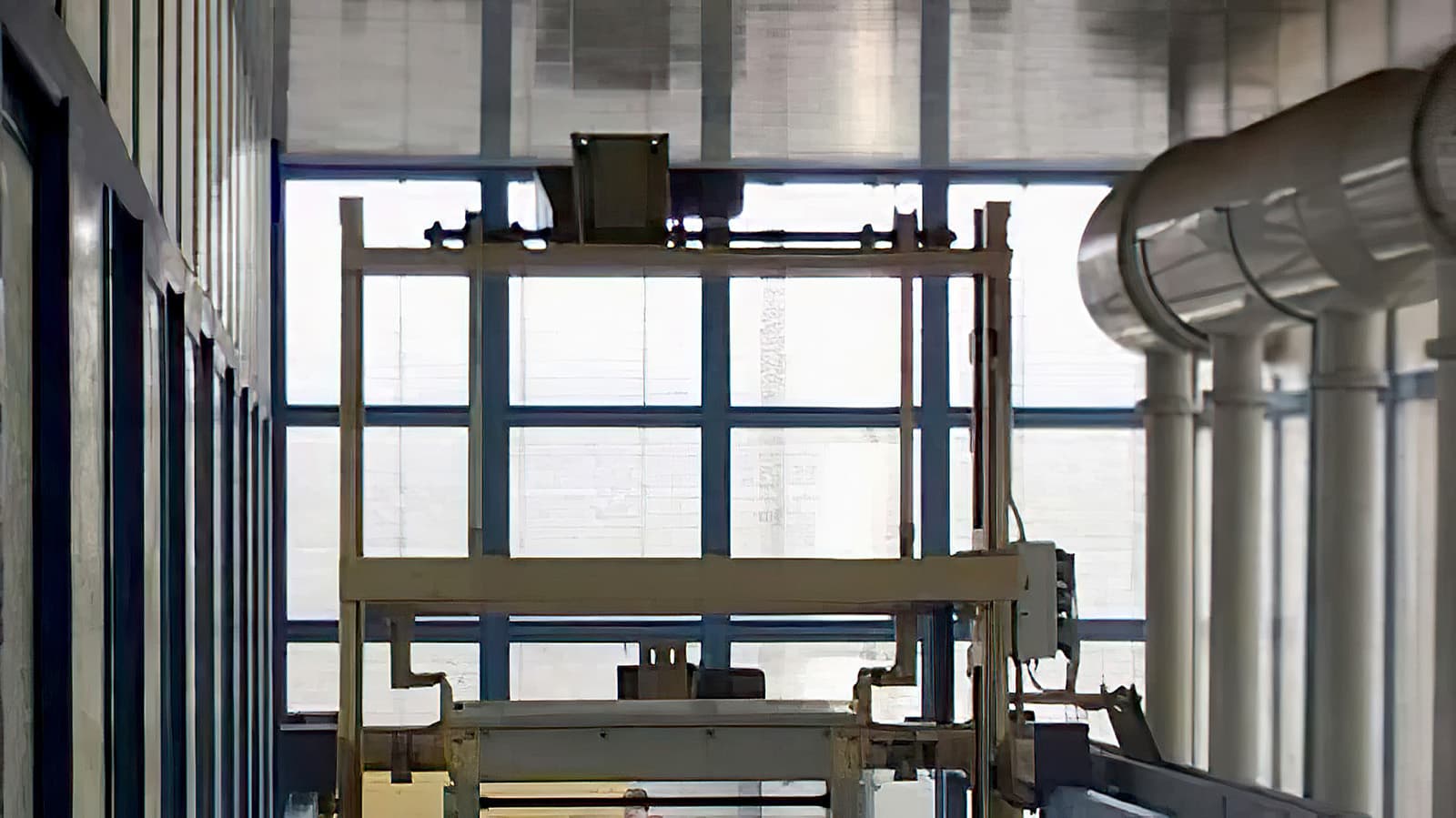

2. Workshop for pretreatment tank

The workshop is designed for pre-treatment before hot-dip galvanizing (rinsing in water, pickling, fluxing, drying). All equipment is installed in a sealed chamber and the pretreatment tank is isolated from the main workshop to ensure that no harmful gases escape into the main workshop.

Workshop dimensions 16.0×5.0×6.0 m.

The main body of the sealed chamber is made of steel, the surface is painted with polyurethane or polymer paint and lined with a UPVC panel for corrosion protection.

The acid gas scrubber is installed outside the sealed room to absorb acid gas and water vapor and ensure that there is a slight negative pressure in the acid cleaning room, completely eliminating the possibility of uncontrolled release of acid mist.

3. Chemical treatment bath

Design of the chemical treatment baths

The pre-processing drum for hardware is made of 8mm stainless steel 316L. The chemical bath automation is controlled by an industrial controller (PLC). When the drum rotates, the cleaned metal products vibrate and collide with each other to effectively clean the surface of the metal products from rust and large particles of dirt. Drum loading capacity 600 ~ 800 kg. The use of a 316L stainless steel drum is due to its durability and smooth line operation. To reduce investment costs, it can be replaced with polypropylene.

The chemical treatment bath is made of welded polypropylene plates, reinforced with metal profiles on the outside. Compared with other materials, polypropylene board has high strength, good corrosion resistance, long service life and beautiful appearance. Each vat is equipped with inlet and outlet pumps and piping.

Number and specification of chemical treatment baths

| Title | Material | Size | Quantity | Note |

|---|---|---|---|---|

| Warm water rinsing bath | welded polypropylene plates (PP) | (L)2.5×(W)1.2×(H)1.2 m | 1 | heat exchanger (* see Note) |

| Pickling bath | (L)2.5×(W)1.2×(H)1.2 m | 5 | heat exchanger (* see Note) | |

| Washing bath in water | (L)2.5×(W)1.2×(H)1.2 m | 2 | ||

| Flux bath | (L)2.5×(W)1.2×(H)1.2 m | 1 | heat exchanger (* see Note) | |

| Drum | stainless steel 316L | φ1200×650 mm | 2 |

4. Hot air drying oven

Belt dryer (drying oven) is designed for drying and preheating products after fluxing before immersing parts in zinc melt. In this case, as a result of the evaporation of water on the surface, a network consisting of salt crystals is formed, which provides protection against oxidation in air.

The material moves inside the dryer on a stainless steel conveyor belt with a suitable coating that is resistant to acid fumes and flux. The conveyor has the ability to adjust the speed of movement.

After drying, the temperature difference between the molten zinc and the product removed from the fluxing bath is reduced and water ingress into the molten zinc is excluded. Drying temperature should not exceed 120°C. The residence time of the hardware in the dryer is until the complete evaporation of moisture from the metal surface (10-60 minutes). After completion of the drying operation, the traverse with its parts is transported to the hot-dip galvanizing bath.

The equipment uses a high temperature long shaft electric motor and multi-blade impellers. The powerful circulation mechanism ensures the best temperature uniformity, low noise level and economy.

| Dimensions | (L)5000 × (W)1300 × (H)1960 mm |

|---|---|

| Furnace hearth size (internal dimensions) | (L)4000 × (W)900 × (H)800 mm |

| Temperature range | 80 ~ 120°C |

| Heating type | electric heating |

| Drive motor | frequency controlled drive |

| Heating method | hot air circulation |

| Installed capacity | 60 kW (380 V) |

| Inner chamber material | 316L stainless steel plate, body material cold rolled steel plate |

| Conveyor belt material | 316L stainless steel |

| Protective devices | overheating protection, motor overheating overcurrent protection, phase sequence protection and others |

5. Hot-dip galvanized ceramic bath

| External dimensions of the zinc bath | (L)5.0 m × (W)2.7 m × (H)2.1 m |

|---|---|

| Internal dimensions of the galvanizing bath | (L)4.0 m × (W)1.2 m × (D)1.6 m |

| Zinc level | 1.4 m |

| Zinc weight | about 48 tons |

| Galvanizing bath operating temperature | 480 ~ 560±2°C |

| Control mode | manual / automatic double control. A three-phase intelligent thyristor regulator allows you to regulate the voltage of heating elements within the range of 0-380V. Each group of heating elements is equipped with an operating status indication device. |

| Temperature control accuracy | ±0.3°C |

| Zinc temperature maintenance accuracy | ±2°C |

| Heating method | ceramic heaters with high thermal conductivity, located on the four sides of the inner wall of the galvanizing bath, ensure a high heating rate and temperature uniformity of the zinc melt |

| Installed power of heaters | 409.5 kW |

| Number of heaters | 63 pcs × 6.5 kW |

| Productivity | from 1.0 to 1.5 tons / hour (depending on the size of the hardware and the specification of zinc coating) |

6. Automatic components for hot-dip galvanizing line

Automatic hot dip galvanizing control system

The hot-dip galvanizing control system allows you to enter the parameters of tens of galvanizing processes into the PLC controller memory. Changing the parameters of the technological process is allowed at any time.

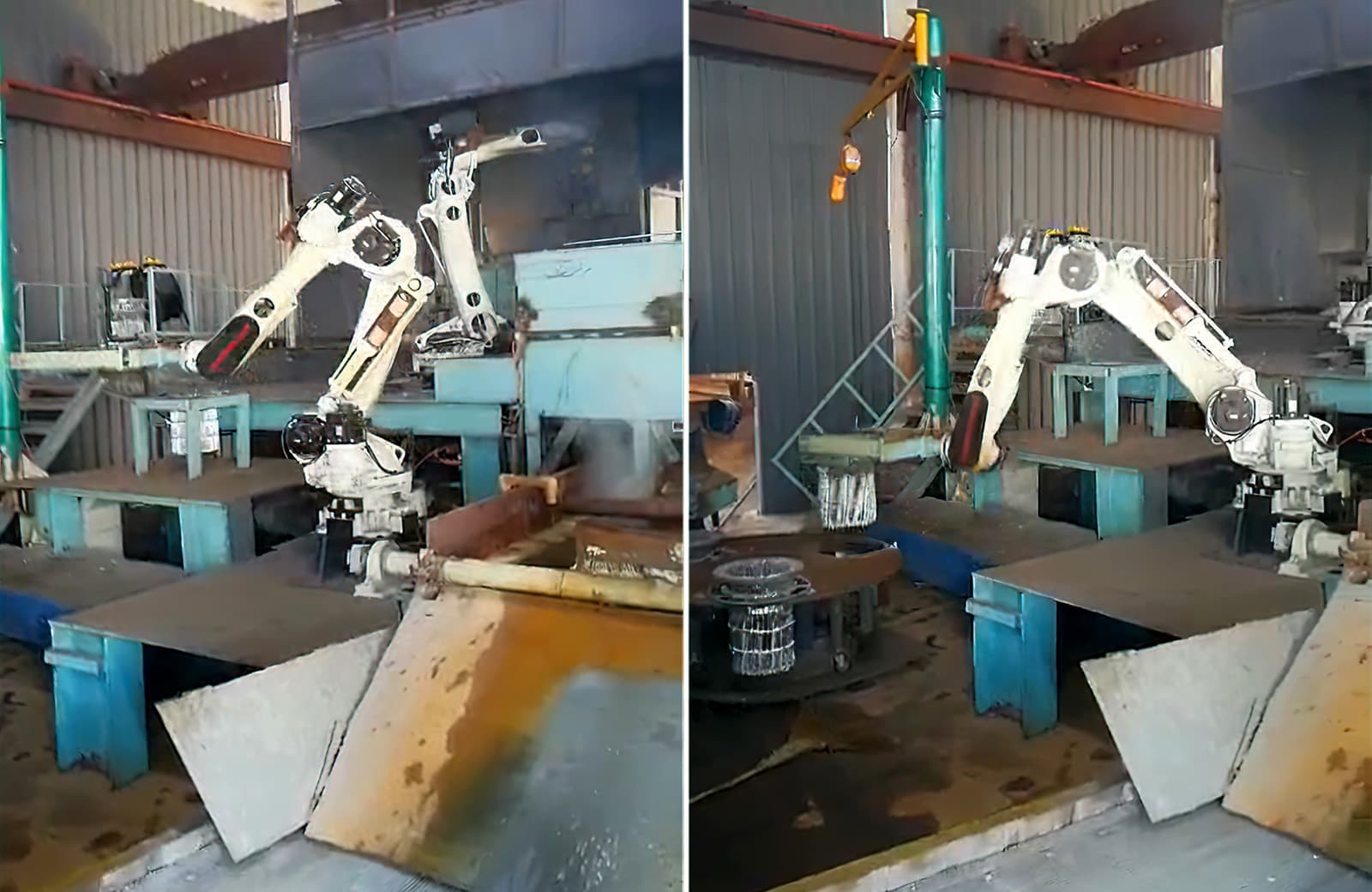

Robots

The automatic hot-dip galvanizing line includes 2 industrial robots. One robot is used for loading and unloading operations. The second robot performs galvanizing operations such as dipping and shaking. This equipment features stable performance and high operational reliability.

Galvanizing baskets are made of 310S stainless steel, which prevents zinc from sticking and guarantees corrosion resistance. Parts are placed in these baskets and during the galvanizing phase they are completely immersed in the zinc melt. The holes in the baskets allow the zinc to flow to the parts to be galvanized. They also allow excess zinc to drain out of the bath. The mechanical hand picks up the basket with the material, which is automatically immersed in the zinc bath with a programmed movement, moves it in the longitudinal direction to complete the cycle after placing the basket in the centrifuge. After that, the basket is sent to the cooling bath and to the unloading position. The movements are performed automatically, without operator intervention.

The average weight of the loaded parts is 25 ~ 35kg.

7. Centrifuge for small parts

After high-temperature galvanizing, small threaded and thin coated parts must be centrifuged to remove excess zinc from the surface. The centrifuge can effectively control the coating thickness, surface smoothness, etc.

By recovering excess zinc, its consumption can be reduced by more than 15%.

The auto-turn centrifuge is a professional equipment used for hot-dip galvanizing of small parts such as fasteners.

The centrifuge is designed for manual loading of workpieces.

Unloading is automatic: after centrifuging, the hopper with the workpieces is automatically lifted and turned over to unload the parts.

An electromagnetic brake is used to brake the centrifuge.

Technical characteristics of the centrifuge

| Loading capacity | ≤25 kg |

|---|---|

| Standard workpiece hopper size (other size on customer request) | Ø500×300 mm |

| Engine power | 7,5 kW (6 steps of power regulation) |

| Electric drive type | frequency-controlled |

| Brake system | electromagnetic clutch brake |

| Unloading workpieces | automatic (mechanical) |

| Opening / closing | automatic (pneumatic) |

8. Passivation and anti-corrosion treatment after galvanizing.

Passivation bath and cooling tank are made of 316L stainless steel. Conveyor for passivation and water cooling baths is made of 316L stainless steel.

Zinc-coated hardware is cooled in a cooling bath in order to lower the temperature and maintain the gloss of the coating. The water temperature in the cooling bath should not exceed 65 ~ 70 °C, so the bath is equipped with a glass fiber reinforced plastic cooler.

Hot dip galvanizing line auxiliary equipment

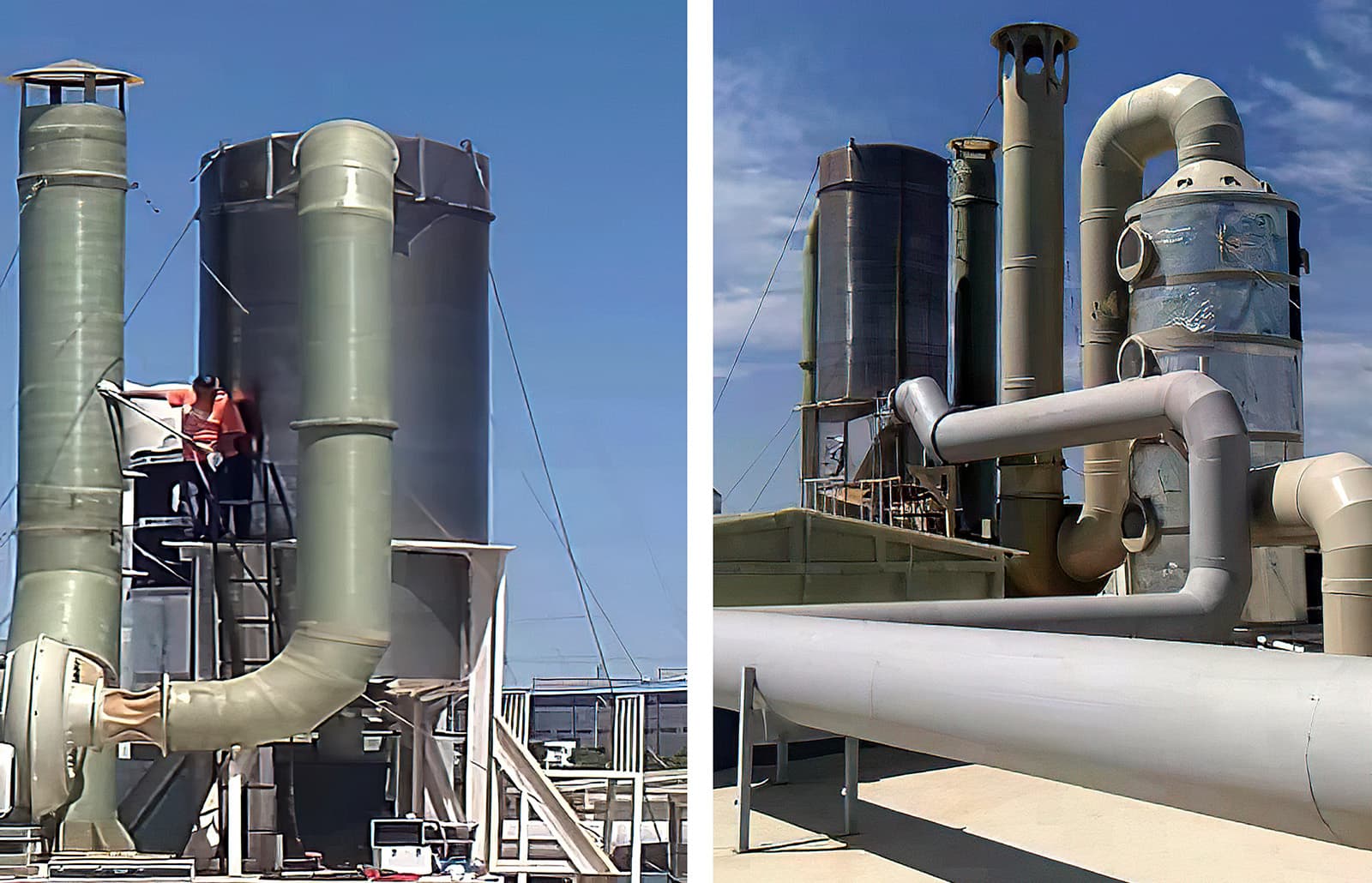

Acid mist scrubber

This equipment for the collection and humidification of acid vapors is connected to the baths with polypropylene pipes. Waste gases containing acid mist pass through a droplet curtain of liquid containing alkaline sorbents. Heavy coagulants are deposited and enter a special receiver, the purified gases are removed from the scrubber. The liquid containing the NaOH absorbent is cyclically sprayed with a water pump.

The scrubber body and piping are made of polypropylene. The equipment is equipped with a variable frequency drive and consumes 45 kW of power.

Smoke and dust cleaning system

When metal products are dipped in a hot-dip galvanizing bath, white fumes are emitted - a product of the decomposition of flux components. They are collected by a sealed suction hood mounted on the galvanizing bath and then piped to a scrubber with a Venturi tube for absorption and filtration. The finally cleaned exhaust gas is transported by an exhaust fan and discharged through the exhaust cylinder.

The sludge, mixed with the sprayed exhaust gas and zinc ash, is collected at the bottom of the scrubber and regularly removed and then sent for recycling.

Constant spray water pressure is provided by a circulation pump. When the liquid level drops, the water replenishment system starts automatically, pumping to the set value, the control system also automatically adds chemicals in accordance with the requirements of the technological process.

Compared to traditional filter cloth bag filters, the flue gas cleaning in the Venturi scrubber is characterized by high cleaning efficiency and low operating costs.

Deironing equipment for flushing water and flux

This automatic equipment reduces the content of iron ions in the wash water and in the flux of the fluxing bath below 1.0 g / L. The processing capacity of the unit is 3m3/hour, the pH value of the flux is 4.0 - 4.5.

The technological process of deferrization is schematic: contaminated flushing water (or flux) → water lifting pump → reaction tank → ammonia control → hydrogen peroxide oxidation → aeration → filter press → clean liquid → return of the regenerated liquid to the original bath.

How iron removal equipment works: rinse water or fluxing electrolyte to be treated is pumped from these vats to the reaction tank of the automatic iron removal equipment. Then H2O2 (hydrogen peroxide) и NH3 (ammonia) are automatically added to the reaction tank; additional aeration ensures complete mixing and speeds up the reaction. The turbid liquid is filtered through a frame filter press, separating into a solid phase (which will later be processed on the side) and into a clean liquid phase, after such processing is pumped back into the working tank. The entire processing process takes place automatically under the control of the PLC.

After deferrization, the flushing water is reused in the production line, no waste water discharge is required, which reduces production costs. Also, the removal of iron ions from the fluxing solution reduces the formation of hartzinc (dros) and ash in the zinc bath and reduces the likelihood of non-galvanizing. In addition, zinc intake is generally reduced.

The iron removal equipment operates in the following working cycle: the frequency of operation is 7-10 days, among them 6-8 days, the equipment processes water for flushing and 1-2 days go to the processing of the fluxing solution.

This equipment can also treat water used for rinsing after pretreatment and rinsing after pickling in order to purify them to comply with the regulations for subsequent discharge into the sewers of an industrial park.