WIRE HEAT TREATMENT FURNACE EQUIPMENT

CONVECTION SHAFT FURNACE FOR SPHEROID ANNEALING OF WIRES AND ROPES

Shaft and bell furnaces are widely used for spheroid annealing of wires, ropes, rods, metal balls, low- and medium-carbon alloy steel.

Shaft furnace and its features

- Temperature control: high precision control of temperature changes, automatic process of heat treatment. The fan is mounted in the bottom of the furnace to ensure stable heat throughout the entire cooking process and maintain a uniform temperature, temperature accuracy is ±5 degrees Celsius.

- Source of heating: electricity;

- Protective atmosphere: ammonia or purified nitrogen protect steel from oxidation, decarbonization, preventing metal loss;

- Capacity: 8 ~ 36 tons, takes small wire parties (≤10 t / party);

- Easy to use and install: the cover of the furnace is equipped with a pneumatic device for opening and closing.

SPECIFICATIONS AND DIMENSIONS OF SHAFT FURNACES

| Model | Diameter of the working zone, mm | Height of the working zone, mm | Outer diameter of the furnace, mm | Height of the furnace, mm | Total height of the furnace , mm | Stand height, mm | Service height, mm | Size of the shaft furnace, mm | Service furnace sizes, mm | Total weight of the furnace, mm | Power | Capacity | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | D | B | E | F | Rack | Without Rack | G × J | Length × Width × Depth | Tone | kW | Tone | |

| RG8355-1 | 2200 | 2000 | 3378 | 3200 | 6930 | 1500 | 7800 | 6300 | 5200 × 5200 | 5200 × 1200 × 1500 | 19.8 | 240 | 2~8 |

| 3000 | 4200 | 7930 | 8800 | 7300 | 22.8 | ||||||||

| RG8355-2 | 2450 | 2000 | 3678 | 3200 | 6930 | 7800 | 6300 | 5450 × 5200 | 5459 × 1200 × 1500 | 21.8 | 280 | 4~14 | |

| 3000 | 4200 | 7930 | 8800 | 7300 | 25.8 | ||||||||

| RG8355-3 | 2800 | 2000 | 3978 | 3200 | 6930 | 7800 | 6300 | 5800 × 5800 | 5800 × 1200 × 1500 | 26.2 | 400 | 8~16 | |

| 3000 | 4200 | 7930 | 8800 | 7300 | 28.5 | 8~22 | |||||||

| RG8355-4 | 3200 | 2000 | 4378 | 3200 | 6930 | 7800 | 6300 | 6200 × 6200 | 6200 × 1200 × 1500 | 29.3 | 500 | ||

| 3000 | 4200 | 7930 | 9800 | 8300 | 32.5 | 8~32 | |||||||

| RG8355-5 | 3600 | 2000 | 4778 | 3200 | 6930 | 8050 | 6550 | 6500 × 6500 | 6500 × 1200 × 1500 | 34.3 | 640 | ||

| 3000 | 4200 | 7930 | 9950 | 8450 | 35.2 | ||||||||

| RG8355-6 | 3700 | 2000 | 4978 | 3200 | 6930 | 8050 | 6550 | 6700 × 6700 | 6700 × 1200 × 1500 | 35.3 | 720 | 8~36 | |

| 3000 | 4200 | 7930 | 9990 | 8450 | 36.3 | ||||||||

BARRELS FEATURES FOR ANNEALING OF WIRES, ROPES AND PARTS IN THE SHAFT FURNACE

- Thanks to the cold forming it is possible to increase the area of heat radiation and the overall strength of the surface of the barrel.

- The insulator provides high-quality thermal insulation and temperature control.

- Barrel can simultaneously receive from 1 to 16 coils of wire/rope (see. Figure).

SPECIFICATIONS FOR BARRELS OF SHAFT FURNACES FOR SPHEROID ANNEALING OF WIRES AND ROPES

| Model | Work diam. of furnace barrels | Outer diament or rope / wire barrels | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 700 mm | 750 mm | 800 mm | 850 mm | 900 mm | 950 mm | 1000 mm | 1100 mm | 1200 mm | 1300 mm | 1400 mm | 1500 mm | ||

| RG-8355-1A | 1800 mm | 2 | 1 | ||||||||||

| RG-8355-1A | 2200 mm | 5 | 4 | 3 | 1 | ||||||||

| RG-8355-2 | 2450 mm | 7 | 6 | 5 | 4 | 3 | 2 | 1 | |||||

| RG-8355-3 | 2800 mm | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | |||

| RG-8355-4 | 3200 mm | 12 | 10 | 9 | 8 | 6 | 5 | 4 | 3 | 2 | |||

| RG-8355-5A | 3500 mm | 13 | 12 | 11 | 9 | 8 | 6 | 5 | 4 | 3 | |||

| RG-8355-5 | 3600 mm | 14 | 13 | 12 | 10 | 9 | 8 | 6 | 5 | 4 | 3 | ||

| RG-8355-6 | 3700 mm | 16 | 14 | 13 | 11 | 10 | 9 | 7 | 5 | 4 | |||

ACCESSORIES AND ADDITIONAL BARRELS FOR SHAFT FURNACES

ACCESSORIES FOR SHAFT FURNACES - METHANOL DECOMPOSITION DEVICE

Device features:

- High productivity.

- Security.

- Tightness.

Principle of operation (chemical reaction):

CH3OH → CO + 2H2

33.3% 66.6%

Decomposition occurs at 930°C

ACCESSORIES FOR SHAFT FURNACES - METHANOL DECOMPOSITION FURNACE

It is used for decarbonization of medium or low carbon steel wire, steel alloy, spheroid annealing.

The furnace uses anhydrous methanol, heated to the decomposition to CO, H2.

CH3OH ⇒ CO↑+ 2H2↑

SPECIFICATIONS

| Type | Methanol consumption, cm3/ h | Temperature, °C (MAX) | power, kW | Weight of equipment, kg |

|---|---|---|---|---|

| RG-25 | 2400 | 1000 | 17 | 1500 |

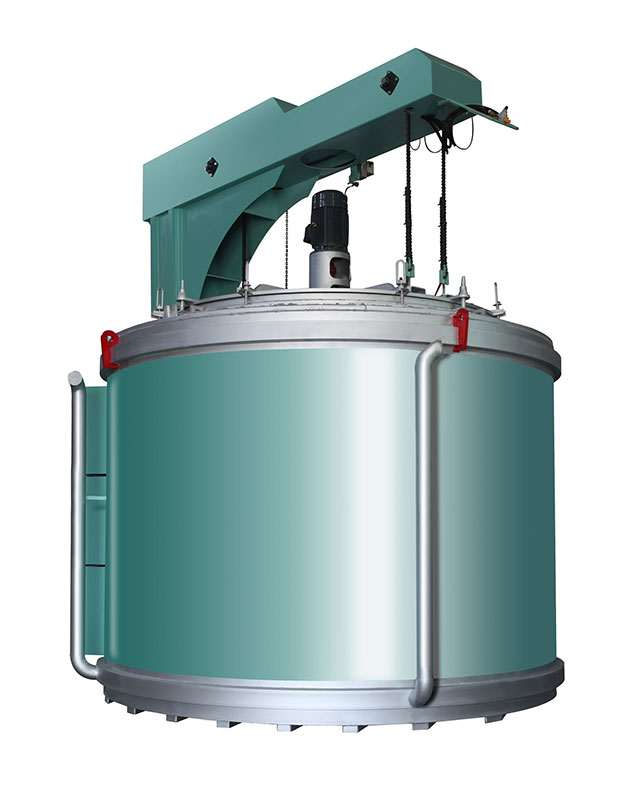

SHAFT FURNACES FOR BRIGHT ANNEALING IN BALL PIT

Shaft furnace appearance

Practical use:

heat treatment, the total treatment of the wire, aluminum alloy, spherical wire, light wire and etc.

Specifications

| Model | Rated power, kW | Nominal temperature, °С | Effective dimensions, mm | Charge weight, kg |

|---|---|---|---|---|

| RG-1 | 180 | 800 | 2000×2000 | 6000 |

| RG-2 | 300 | 800 | 2200×2000 | 8000 |

| RG-3 | 400 | 800 | 3200×2000 | 16000 |

| RG-4 | 480 | 800 | 3200×3000 | 20000 |

| RG-5 | 580 | 800 | 3500×3200 | 30000 |

PIT-TYPE ANNEALING FURNACE

Pit-type annealing furnace has a cylindrical housing welded with angle steel and steel plate. Inside housing, the pit-type furnace is made of light fire bricks. After work pieces that are to be heated are put into charging basket, they will be sent in or taken out through workshop hoisting equipment. Electrical equipments adopt controllable silicon, carrying out PID regulation and control by program control. It is suitable for the annealing of wire rod linear materials, copper pieces, stainless steel, and steal belt. Rush into nitrogen under vacuum state for annealing, non-nitriding, and non-decarburization, so as to make work pieces keep bright after annealing.

Purpose

- Provide annealing heat treatment for all kinds of steels at rated temperature.

- Annealing and tempering work after heat treatment quenching.

- Eliminate the stress of all kinds of steels or non-iron materials.

Equipment Introduction

- Movable-type furnace cover, equipped with PLC control system; excellent operability and accuracy.

- Welded by shaped steel and steel plate; bottom is made of high-alumina bricks; height and weight resistance.

- Furnace cover adopts guide rail combined move mode; go up and down by air pressure or oil pressure; good stability.

- Electronic type temperature control recorder; can observe and read history records, and make best monitoring at any time.

- Automatic control system and man-machine management interface; make management become more efficient.

Characteristics

- Electric power heating.

- Good tightness; specially designed convection system, which makes furnace temperature uniform.

- Thermal insulation material is ceramic cellucotton, light weight, good thermal insulation effect, quick warming and cooling speed.

- There is an air spacer sleeve between furnace pipe wall and water loop, which effectively reduces thermal energy loss.

- Have a system that compulsorily reduces temperature, save discharge time, increases productivity, and reduces cost.

- Temperature control adopts optimized PID control system, rapidly reach steady state; high precision.

Pit-type Annealing Furnace Specification

Relevant sizes list of annealing furnaces (electric heating type)

Applicable range -> the softening and spheroidizing of annealing hardware wires

| Unit: mm | ||||||

|---|---|---|---|---|---|---|

| Model | Usage diameter | Width of furnace body | Diameter of furnace body | Height of furnace body | Height of travelling cranes | Tonnage |

| RGP-100/200E | 1000 | 2880 | 2240 | 3220 | 5020 | 2T |

| RGP-210/200E | 2100 | 3980 | 3340 | 3220 | 5020 | 6T |

| RGP-240/200E | 2400 | 4280 | 3670 | 3230 | 5040 | 8T |

| RGP-280/200E | 2800 | 4680 | 4070 | 3230 | 5040 | 14T |

| RGP-310/200E | 3100 | 4980 | 4370 | 3230 | 5090 | 16T |

| RGP-360/320E | 3200 | 5080 | 4470 | 4430 | 5090 | 16T |

| RGP-360/320E | 3600 | 5480 | 4870 | 4430 | 5090 | 20T |

SPECIFICATIONS OF SHAFT FURNACES FOR WIRE ANNEALING

Maximum temperature: >850°C

Capacity: 6 - 40 tons / furnace

| Type | Size, mm | Power. kW | Temperature, °C (MAX) | Capacity (MAX) (kg/furnace) |

|---|---|---|---|---|

| RGBP-2020 | Ø2000×2000В | 180 | >850 | 6000 |

| RGBP-2420 | Ø2450×2000В | 240 | >800 | 8000 |

| RGBP-2820 | Ø2800×2000В | 280 | >800 | 14000 |

| RGBP-3024 | Ø3000×2400В | 350 | >800 | 25000 |

| RGBP-3530 | Ø3500×3000В | 380 | >800 | 40000 |

EQUIPMENT OF THE FURNACE

Standard equipment of the furnace includes:

- Heater

- Working base

- Internal coating

- Temperature control system

Optional equipment of the furnace includes:

- the system of atmosphere control;

- endothermic gas denaturation furnace;

- the tilting mechanism for coils of wire;

- wire rack;

- a reservoir for storing gas.