WIRE HEAT TREATMENT FURNACE EQUIPMENT

PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING LINEAR FURNACE FOR BRIGHT ANNEALING BATCH ANNEALING FURNACE / CONTINUOUS ROLLER FURNACE

CHAMBER TYPE SPHEROIDIZING ANNEALING FURNACE

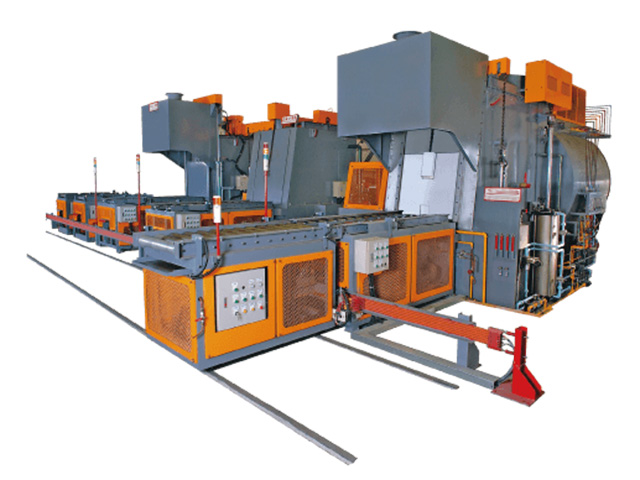

Chamber Type Spheroidizing Annealing Furnace series RG-641

Automatic Temperature Control Panel series RG-642

Technical Specifications of Chamber Furnaces series RG-641

| Model | Outside Dimension (mm) | Effective Dimension (mm) | Total Length (mm) | Output (A) (kg) | Output (B) (kg) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Height | Length | Width | Height | ||||

| RG-641-1A/B | 9100 | 3000 | 4735 | 7200 | 1800 | 2400 | 25500 | 16000 | 32000 |

| RG-641-2A/B | 10900 | 3000 | 4735 | 9000 | 1800 | 2400 | 30900 | 20000 | 40000 |

| RG-641-3A/B | 12700 | 3000 | 4735 | 10800 | 1800 | 2400 | 36300 | 24000 | 48000 |

| RG-641-4A/B | 14500 | 3000 | 4735 | 12600 | 1800 | 2400 | 41700 | 28000 | 60000 |

Features and benefits of the equipment:

- Chamber furnaces are ideal for spheroid annealing and soft annealing of high / medium / low carbon steel wire, low / medium carbon alloy wire rods, tubular parts, forging material, and also can be designed for tempering and normalizing treatment..

- Gas burners made in the USA are used.

- Furnaces are equipped with CO / CO2, O2 control system and automatic operator control panel.

- The temperature of the heat treatment: 200-900°С.

- Gas used: Nitrogen + RX, nitrogen + gas based methanol decomposition, NX + RX.

MULTI-PURPOSE CHAMBER FURNACE

Description

Multi-Purpose Chamber Furnace collocates with Washing, Tempering, Loading and Unloading Stations creating a full heat treatment production line, which is suitable for carburizing, hardening, carbonitriding, carbon surface coating, bright quenching, etc. This type of furnace is suitable for multiple heat treatment processes.

Multi-Purpose Chamber Furnace RG-701

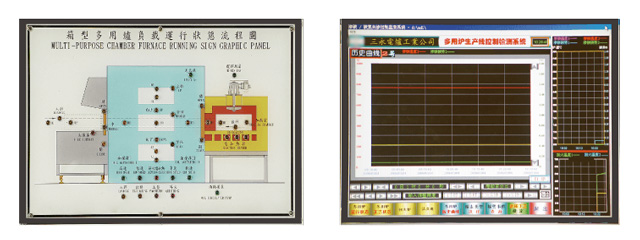

Automatic Temperature Control Panel series RG-707

Features

- Temperature control system: Furnace uses SSR and PID for temperature adjustment.

- Carbon potential control system: uses O2 oxygen probe and USA carbon potential controller. It can control the atmosphere precisely.

- Action program control system:

- PLC

- According to customer’s requirements, industrial PC can be configured to be the main control system that monitors the temperature, carbon potential action program control system; it also participates in the development process, process management, and dynamic tracking control with LCD display and recording functions.

Computer Program Control System RG-708

The Output and Electricity of Full-Line Multi-Purpose Chamber Furnace

| Model | Effective Dimension (mm) | MAX. Productivity / Furnace (kg) | Heating Power (kw) | Top Temperature (°C) | Heating Ability To 850℃ (kg/h) | Capacity of Quenching Oil TankL | Outside Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||||||

| RG-701-1 | 600 | 1200 | 600 | 600 | 115 | 950 | 475 | 7600 | 3065 | 5174 | 3755 |

| RG-701-2 | 700 | 1200 | 700 | 800 | 126 | 950 | 540 | 8500 | 3165 | 5174 | 3955 |

| RG-701-3 | 760 | 1200 | 800 | 1000 | 135 | 950 | 565 | 9500 | 3225 | 5174 | 4155 |

RG-701 Quenching Furnace

| Model | Outside Dimension (mm) | Capacity of Quenching Oil (L) | Output (kg) | (Quenching Oil) Top Temperature (°C) | Top Temperature (°C) | (Quenching Oil) Power (Kw) | Power (Kw) | Effective Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | |||||||

| RG-701-1 | 2920 | 5044 | 3914 | 7600 | 600 | 120 | 950 | 60 | 115 | 600 | 1200 | 600 |

| RG-701-2 | 3020 | 5044 | 4014 | 8500 | 800 | 120 | 950 | 60 | 126 | 700 | 1200 | 700 |

| RG-701-3 | 3080 | 5044 | 4114 | 9500 | 1000 | 120 | 950 | 60 | 135 | 760 | 1200 | 800 |

RG-702A Degreasing Tank

| Model | Outside Dimension (mm) | (Capacity of Degreasing Tank) Cleaning Agent Tank / Water Tank (L) | (Degreasing Circulation Pump) Cleaning Agent Tank / Water Tank (Hp) | (Power)Cleaning Agent Tank / Water Tank / Drying (Hp) | Effective Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||||

| RG-702A-1 | 2090 | 3700 | 3000 | 3000 / 2500 | 2 / 3 | 72 / 36 / 45 | 600 | 1200 | 600 |

| RG-702A-2 | 2190 | 3700 | 3100 | 3200 / 2700 | 2 / 3 | 72 /36 / 45 | 700 | 1200 | 700 |

| RG-702A-3 | 2250 | 3700 | 3200 | 3400 / 2900 | 2 / 3 | 72 / 36 / 45 | 760 | 1200 | 800 |

RG-702B Degreasing Tank

| Model | Outside Dimension (mm) | Capacity of Degreasing Tank (L) | Degreasing Circulation Pump (Hp) | (Power) Cleaning Agent Tank (Kw) | Effective Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||||

| RG-702B-1 | 1780 | 3000 | 3225 | 3500 | 3 | 72 | 600 | 1200 | 600 |

| RG-702B-2 | 1880 | 3000 | 3325 | 3700 | 3 | 72 | 700 | 1200 | 700 |

| RG-702B-3 | 1940 | 3000 | 3425 | 3900 | 3 | 72 | 760 | 1200 | 800 |

RG-703 Tempering Furnace

| Model | Outside Dimension (mm) | Output (Kg) | Top Temperature (°C) | Power (Kw) | Effective Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||||

| RG-703-1 | 1610 | 2200 | 3230 | 600 | 700 | 70 | 600 | 1200 | 600 |

| RG-703-2 | 1710 | 2200 | 3330 | 800 | 700 | 90 | 700 | 1200 | 700 |

| RG-703-3 | 1770 | 2200 | 3430 | 1000 | 700 | 115 | 760 | 1200 | 800 |

RG-704 Preparatory Table

| Model | Outside Dimension, mm | Roller Driving Device Geared Motor, HP | Effective Dimension mm | ||||

|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||

| RG-704-1 | 900 | 1700 | 1100 | 1 | 600 | 1200 | 600 |

| RG-704-2 | 1000 | 1700 | 1100 | 1 | 700 | 1200 | 700 |

| RG-704-3 | 1060 | 1700 | 1100 | 1 | 760 | 1200 | 800 |

RG-705 Receiving Table

| Model | Outside Dimension, mm | Roller Driving Device Geared Motor, HP | Effective Dimension, mm | ||||

|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | ||

| RG-705-1 | 900 | 1700 | 1100 | 1 | 600 | 1200 | 600 |

| RG-705-2 | 1000 | 1700 | 1100 | 1 | 700 | 1200 | 700 |

| RG-705-3 | 1060 | 1700 | 1100 | 1 | 760 | 1200 | 800 |

RG-706 Loading & Unloading Transported Cart

| Model | Outside Dimension, mm | Roller Driving Device Geared Motor, HP | Trolley Running Device Geared Motor, HP | Effective Dimension, mm | ||||

|---|---|---|---|---|---|---|---|---|

| Width | Length | Height | Width | Length | Height | |||

| RG-706-1 | 900 | 1740 | 1100 | 1 | 1 | 600 | 1200 | 600 |

| RG-706-2 | 1000 | 1740 | 1100 | 1 | 1 | 700 | 1200 | 700 |

| RG-706-3 | 1060 | 1740 | 1100 | 1 | 1 | 760 | 1200 | 800 |

CHAMBER FURNACE FOR WIRE SPHEROID ANNEALING COMPLETED PROJECTS

Left view of the furnace

Right view of the furnace

Work platform for furnace maintenance

ECLIPSE Gas burners, made in the USA

Front view of the furnace. Feeding wire in coils

Back view of the furnace. Unloading unit for finished products

Front view of the furnace.

Feeding wire in coils.

Feeding wire in coils.

Back view of the furnace.

Unloading unit for finished products.

Unloading unit for finished products.

Side view of the chamber furnace

Work platform for furnace maintenance