Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

WIRE PROCESSING EQUIPMENT

STEEL WIRE HEAT TREATMENT LINE

Wire patenting - heat treatment of steel wire (heating to 870-950°C, cooling to 450-550°C in salt or lead melt, isothermal holding and further cooling in air or in water) used to obtain a thin-plate ferrite-carbide microstructure. The purpose of patenting is to improve the ductility of the metal.

Before drawing, the wire is patented. In this case, supercooled austenite turns into a thin-plate structure - sorbitol. This is one of the methods of isothermal hardening in the preparation of metal for cold drawing with a large total compression.

Usually, after isothermal heat treatment, the metal undergoes subsequent deformation with large degrees (up to 90%).

The patented wire with the same strength as hardened and tempered, withstands large degrees of compression and acquires much higher properties after drawing. The patented wire has higher strength and elasticity than hardened and tempered wire after drawing: in the first case, the hardening achieved by heat treatment is supplemented by mechanical hardening during drawing, while in the second case, this mechanical hardening is significantly reduced as a result of recrystallization occurring when heated to hardening.

The patented wire is used to produce high strength wire rope and spring wires (the big advantage of the patented wire is that the winding springs do not need to be hardened).

Steel Wire Patenting Line Application

- Patenting and surface preparation for steel wire to make sure the drawing process goes smoothly and successfully.

- Making hot-finished steel wire rod to have appropriate sorbate content to ensure that the drawing can be carried out normally.

- Making steel wire’s organization special.

- Increasing wire’s performance after drawing.

Equipment Advantages

- Brightening of the wire surface, no damage to the surface of the wire.

- Low operating cost, high efficiency and energy-saving.

- Beautiful construction, simple and safe to operate and maintain.

- European and American advanced technology.

Carbon content: 0.4-1.0%, Wire diameter – Ø0.6 - 2.8 mm (According to customer’s requirements)

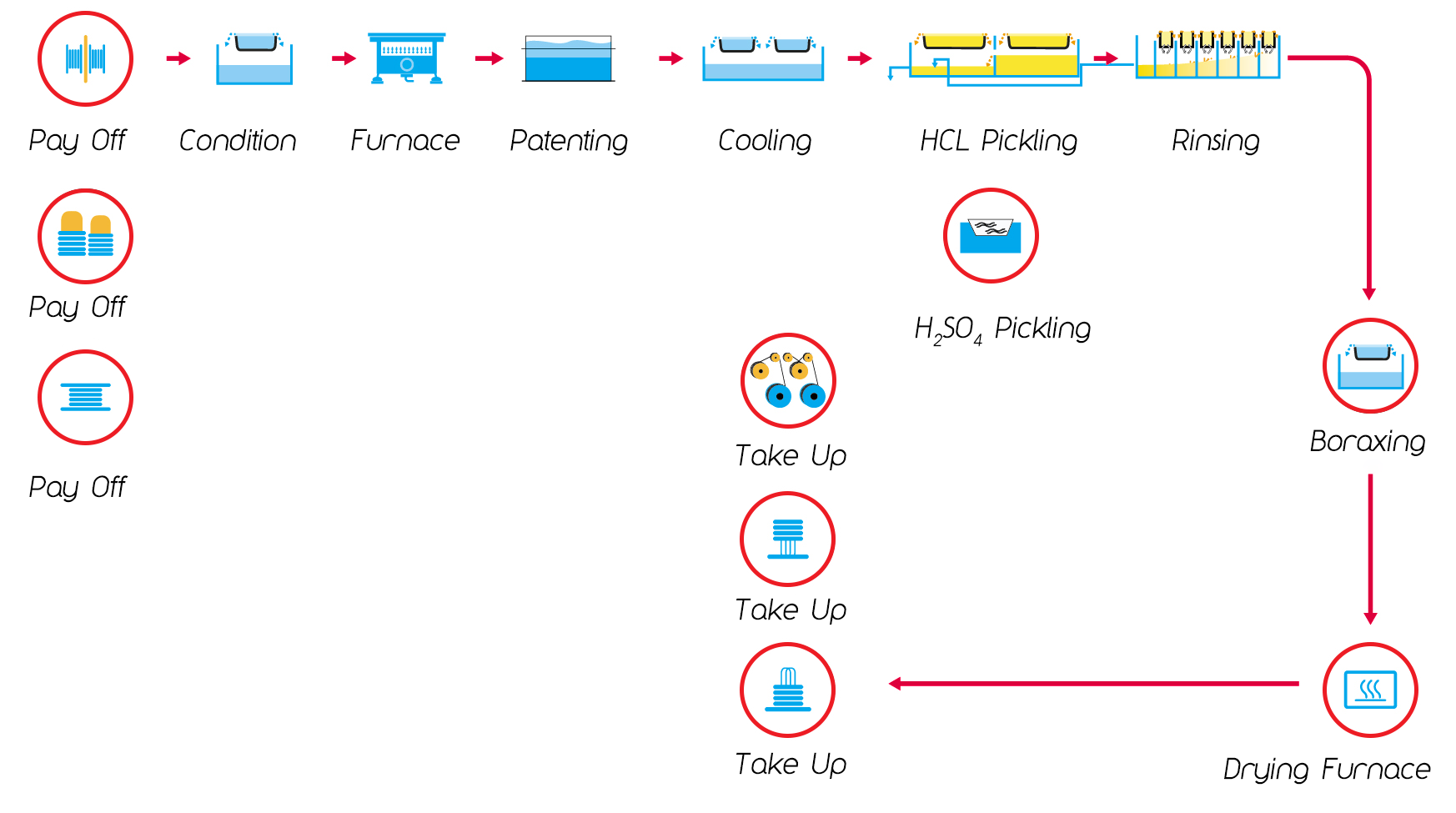

Process Step of Steel Wire Patenting

The wire patenting line consists of an unwinding mechanism for wires in a thread; degreasing and washing baths, preheating unit; patenting unit; cooling baths; pickling baths; baths for applying a lubricant coating, washing and drying; vertical winding devices and tension devices.

Theoretically, patenting is the rapid cooling of the wire in the austenitic state to a preset temperature with subsequent holding for more than the time of isothermal decomposition at this temperature to obtain a sorbitol structure.

The sequence of the steel wire patenting: Pay off Wire adjustment Furnace Patenting Quench Acid Picking Rinsing Boraxing Dry Furnace Take up.

Technical parameters of the Steel Wire Patenting Line

| Material | Carbon content 0.4 - 1.0% |

|---|---|

| Wire diameter | Ø0.6 - 2.8 mm |

| Wire number | 8 - 40 (according to customers' requirements) |

| Line speed | 10 - 75 m/min |

| Weight of coating | 4 - 8 g/kg |

| Working hours | 24 hours continuously |

| Production capacity | According to customer’s needs |

Video of the Operation of the Steel Wire Patenting Line

Information required for the proposal

Which information is needed to make a proposal?

- Wire material.

- Diameter range.

- Wire numbers.

- Coating weight.

- Capacity.

- Pay-off and take-up method: spool/bobbin, spindle, spider / other.