Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

WIRE / BAR STRAIGHTENING AND CUTTING

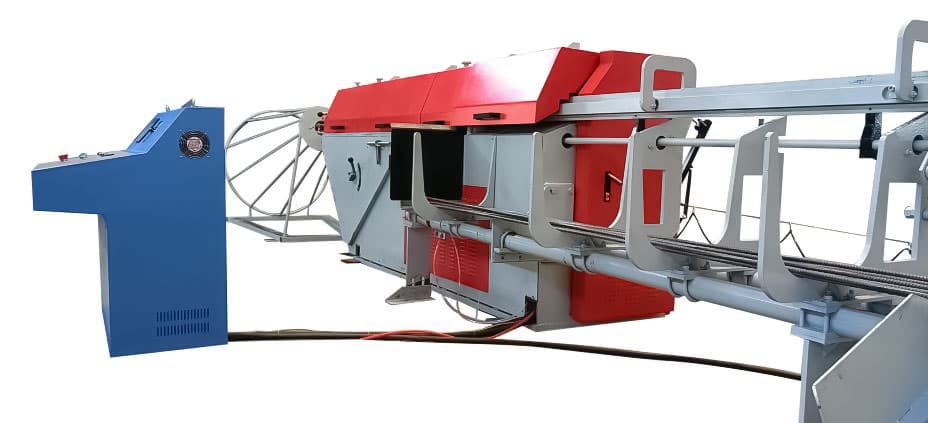

STEEL WIRE STRAIGHTENING AND CUTTING MACHINE RG10-16 Series

This model of straightening and cutting equipment is designed for the production of rebar Ø10-16 mm according to the "coil to rod" pattern.

Technical Advantages

- Suitable for straightening and cutting cold-rolled round bar/ ribbed bar, hot-rolled round/ ribbed bar.

- High cutting accuracy: length tolerance ≤±1 mm.

- High straightness: ≤2 mm/m.

- 4 working speeds: 70 m/min, 100 m/min, 130 m/min and 150 m/min.

- Normally working speed: 130 m/min. If you finish product length less than 2 m, suggest 70 - 100 m/min.

- Intelligent control: the machine is controlled by PLC Siemens, touch screen Weinview and servo motor EURA Drives servo. Easy operation and working reliable.

- Low failure rate: due to the fine processing of parts and strict quality control, after installation and debugging, under normal working conditions, it can maintain trouble-free operation for a long time.

- World Advanced & Leading technology: machine straightening and cutting technology.

Technical Data

| Model | RG10-16 | RG10-16S |

|---|---|---|

| Steel Wire Diameter | Ø10 - 16 mm cold rolled & hot rolled round bar/ rebar | |

| Wire Length | 0.6 - 12 m, adjustable or customized | |

| Rebar Collect Stacker | 12 m | |

| Length Tolerance | ≤±1 mm | |

| Straightness | ≤2 mm/m | |

| Working Speed | 70 - 100 - 130 m/min | |

| Load capacity of Pay-off | 3000 kg | |

| Straightening Mode | Rotating Straightening Drum | |

| Wire Feeding Mode | Electric Motor | |

| Total Motor Power | 45+7.5 kW | 55+7.5 kW |

| Cutting Mode | Servo Motor Cutting | |

| Servo Motor Power | 7.5 kW | |

| Control Mode | PLC (Siemens) | |

| Steel Wire Strength | Tensile Strength ≤550 MPa Low Carbon Steel Wire | |

| Electric Voltage | Three Phase, 380V, 50Hz | |

| Power Supply Line | Cross-sectional Area 6 mm2, Material: Copper Material | |

| Air consumption | Working Pressure 0.6 MPa, Flow Rate 18 m3/h (0.3 m3/min) | |

| Working Line Size (L×W×H) | 30×3×2 m | |

| Gross Weight | 5500 kg | 5800 kg |

REBAR STRAIGHTENING AND CUTTING LINE RG5-12 Series

This rebar straightening and cutting machine is designed for the production of reinforcing bars Ø5-12 mm according to the "coil-to-rod" pattern.

Technical Data

| Model | RG5-12 |

|---|---|

| Rebar diameter | Ø5 - 12 mm |

| Cut-off Length | 0.8 - 12 m (сould customized according to client’s requirements) |

| Rebar Collect Stacker | 12 m |

| Length accuracy | ≤±2 mm |

| Length adjust mode | Manual / Automatic |

| Pulling speed | 120 - 150 m/min |

| Load capacity of Pay-off | 3000 kg |

| Cutting Mode | Servo Shear |

| Control Mode | PCC (Programmable Computer Controller) |

| Speed Control | steplessly adjustable |

| Tensile strength of material | σb = 210 - 650 MPa |

| Electric Voltage | Three Phase, 380V, 50Hz |

| Total power | 46.5 kW |

| Dimension (L×W×H) | 2.6×1×1.98 m |

| Gross Weight | 3000 kg |

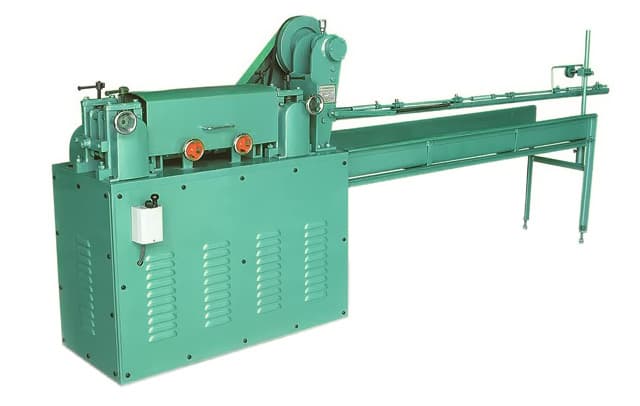

WIRE / BAR STRAIGHTENING AND CUTTING MACHINE

This Wire/Bar Straightening and Cutting Machine utilizes the principle that the wire will be straightened while rotating at high speed and being drawn at the same time.

Wire Straightener and Cutter consists of two units of straightening roller and Set length & Cutter Seat. Metal is moved by a feeding roller, straightened by a straightening roller, and taken into the Set-Length & Cutter-Seat by Outlet Feeding Roller.

The set length & Cutter Seat consist of Thread Stripper and Cutting Arm. When Metal wire is taken into inlet feeding roller and revolve the straightening roller, a Counter will count and rule the cutting length. After cutting, the cutting rod makes the Thread Stripper move and the finished product falls into the collector.

WIRE / BAR STRAIGHTENING AND CUTTING MACHINE RGC-S SERIES

Specification of Wire straightening and cutting Machine RGC-S Series

| Model | Wire Diameter | Wire Cut Length | Speed | Power Required |

|---|---|---|---|---|

| RGC-S9 | Ø5 - Ø9 | 1m – 12m | 80 m/min | 30HP/5HP/5HP |

| RGC-S12 | Ø8 - Ø12 | 1m – 12m | 120 m/min | 40HP/15HP/7-1/2HP |

| RGC-S20 | Ø12 – Ø16 | 1m – 12m | 80/56/38/24 m/min | 50HP/10HP |

| RGC-S25 | Ø16 – Ø25 | 1m – 12m | 23 m/min | 50HP/10HP/25HP |

| RGC-S30 | Ø20 – Ø30 | 1m – 12m | 15 m/min | 60HP/15HP/40HP/1HP(7X) |

WIRE /BAR STRAIGHTENING AND CUTTING MACHINE RG-K SERIES

Wire / Bar Straightening and Cutting Machines are designed for straightening-measuring-cutting any kinds of metal wire/bar or non-metal wire/bar such as, steel bar for construction, welding rods, netting - wire, fan netting hanger, refrigerator netting, shopping basket, shoes rack, book stand, domestic fowls cage, record stand and the other kinds of steel wire etc.

The Wire/Bar Straightener and Cutter is easy to operate. You just need to fix the adjuster to the desired length, and feed the wire/bar into the machine. Then, the machine automatically produces straight wire/bar of uniformed length at a high speed.

Moreover, it rotates smoothly and noiselessly; it is precise in its measure and strong in its structure. During the operation, the feeding of wire/bar and the cutting action are ceaselessly continued by the shifting of a cutter cooperatively.

RG-K Series Wire straightening and cutting Machine Specifications

| Model | Required Power | Wire diameter | Speed | Cut wire length |

|---|---|---|---|---|

| RG-K-1 | 1HP+1/2HP | Ø1.5mm~Ø3.5mm | 35m/min | 6 feet |

| RG-K-2 | 1HP+2HP | Ø3mm~Ø6mm | 35 m/min | 6 feet |

| RG-K-3 | 10HP | Ø5mm~Ø8mm | 35 m/min | 10 Feet |

| RG-K-4 | 2HP+20HP | Ø7mm~Ø12mm | 35 m/min | 20 feet |

| RG-K-5 | 2HP+20HP+3HP | Ø10mm~Ø15mm | 11m/min, 22 m/min, 34 m/min, 49 m/min | 20 feet |

Hydraulic bending tools

| Model | Bending Angle | Curving Ability | Weight |

|---|---|---|---|

| НВВ-32 | 0~90° | 32 mm | 19 kg |

| НВВ-25 | 0~90° | 32 mm | 11.5 kg |

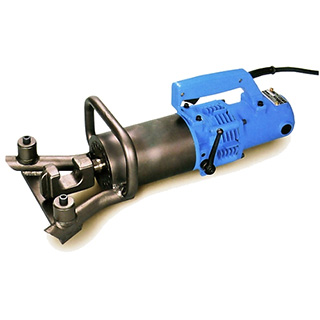

Hydraulic cutting tools

| Model | Electric Voltage | Electric Current | Cutting Capacity | Cutting speed | Cutting Force | Weight | Size (L × W × H) |

|---|---|---|---|---|---|---|---|

| RGT16 | 110V / 220V, 50/60Hz | 9A / 4.5A | Ø4 ~ Ø16 mm | 1.5 sec | 10 t | 7 kg | 340 × 107 × 236 mm |

| RGT20 | 11A / 5.5A | Ø4 ~ Ø20 mm | 3 sec | 15 t | 13.5 kg | 416 × 116 × 220 mm | |

| RGT32 | 14A / 7A | Ø20 ~ Ø32 mm (standard cutter blades) Ø4 ~ Ø20 mm (larger cutter blades) | 6 sec | 55 t | 46 kg | 580 × 190 × 300 mm |

Hydraulic cutting tools with rechargeable batteries

| Model | Cutting ability | Weight | Cutting speed |

|---|---|---|---|

| НСС-13 | 13 mm | 4 kg | 2.5 sec |

| НСС-16 | 16 mm | 4.5 kg | |

| НСС-19 | 19 mm | 5 kg |

Hydraulic cutting tools

| Model | Cutting ability | Weight | Cutting speed |

|---|---|---|---|

| НВС-301 | 13 mm | 5.3 kg | 1.5 sec |

| НВС-316 | 16 mm | 7.8 kg | |

| НВС-19 | 19 mm | 11.8 kg | |

| НВС-25 | 25 mm | 20 kg | |

| НВС-32 | 32 mm |