Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

WIRE PLATING EQUIPMENT

WIRE SURFACE TREATMENT LINES COMPONENTS

Pay-off Machine

C-hook type

Pay-off

| Material | Carbon Wire |

|---|---|

| Wire Diameter | Ø4 - Ø10 mm |

| Line Speed | < 120 m/min |

| Application | Pre-treatment |

Vertical Spool

Pay-off

| Material | Carbon Wire |

|---|---|

| Wire Diameter | Ø0.8 - Ø4 mm |

| Line Speed | < 80 m/min |

| Application | Patenting / Galvanizing / Phosphate |

Turning Arm of Spool

(Manual & Automatic)

| Material | Carbon Wire |

|---|---|

| Wire Diameter | Ø0.6 - Ø2.6 mm |

| Line Speed | < 80 m/min |

| Application | Patenting / Brass plating / Phosphate |

Vertical Spindle

Pay-off

| Material | Carbon Wire |

|---|---|

| Wire Diameter | Ø2.5 - Ø3.5 mm |

| Line Speed | DV: 50-120 mm.m/min |

| Application | Brass Coating / Galvanizing / Phosphate |

Steel Wire Descaling Machine

Technical Process Tank

| Material | Frame | Line Speed | Length of Tank | Application |

|---|---|---|---|---|

| Carbon Wire | Welded PPH structure | DV:50-120 mm.m/min | Design Base Requirement | All production line |

Rising Cover Pickling Tank

| Material | Wire Diameter | Frame | Line Speed | Tank Length | Acid Type |

|---|---|---|---|---|---|

| Carbon Wire | Ø0.5~Ø8.0 | Welded PPH structure | Design Base Requirement | Design Base Requirement | HCL or H2SO4 |

Water Air Patenting

| Material | Wire Diameter | Wire Number | Heating Method | Line Speed | Strength of Wire |

|---|---|---|---|---|---|

| Carbon Wire 0.45~0.92% | Ø0.8~Ø4.0 | Based on design | Steam | DV:50-120 mm.m/min | 45# - 920MPa 60# - 1070MPa 70# - 1170MPa 80# - 1270MPa |

| Appearance (stock solution) | ASTM chromaticity | Viscosity (37.8°C) | Specific gravity (15.6°C, g/cm3) | PH | Water-soluble | Corrosion resistance |

|---|---|---|---|---|---|---|

| Light amber opaque liquid | 0.5 | 555±25CST | 1,067 | 9,0±0.59 (weak alkaline) | Easily soluble | The corrosion resistance of the aqueous solution within 5% is excellent. |

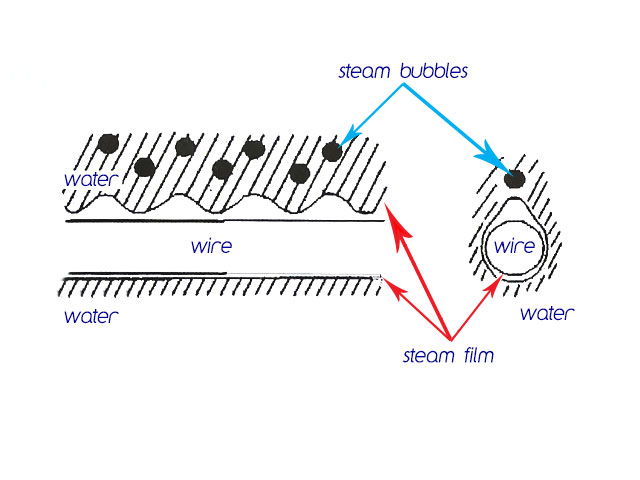

Cooling mechanism

In general, the cooling state (organization tumover happens in cooling procedure) of steel wire in water can be described as 3 states:

- Nuclear boiling: water direct contacts with metal surface and furious boiling occurs, a large number of bubbles are generated, intense liquid convection cooling accompanies in the meantime.

- Film boiling: all water surrounding metal gasifies, and forms a steam membrane to cover whole steel wire, metal heat emits via heat conduction and heat radiation inside the membrane, as well as flow of fluid surrounding steam membrane. Because metal and water is insulated by steam membrane, metal cooling speed drops rapidly. The more stable steam membrane is, the thicker the membrane is, and the slower the cooling speed is. Along with thickening of steam membrane, small and homogeneous bubbles are generated by surface tension escape from water.

- Convective heat transfer: because temperature of metal surface is lower than temperature of water boiling, so natural convective heat dissipation happens by temperature difference. Steel wire dips into water at Ac3 or Acm temperature and starts cooling from nuclear boiling state, and soon enters into film boiling state, then returns to nuclear boiling state along with temperature drops (because steam pressure inside membrane cannot maintain stabilization of membrane), and finally enters into Convective heat transfer state;

Natural Gas Furnace

Material: Carbon Wire. DV: 50-120 mm.m/min. Wire diameter: Ø0.8-13.0 mm. Wire number: Based on design

The N.G. furnace is about 27 meters, and each heating section is relatively independent and influenced each other. According to the requirements of heat treatment process, the furnace temperature and atmosphere can be set up in order to meet the process requirements.

The furnace body is divided into five heating sections, and each section separately controls the temperature and regulates the atmosphere. The pre-mixed gas heating technology of Belgium FIB company was selected, and several FIB type premix burners were installed in each heating section.

Each heating section is calculated and adjusted by the temperature regulator according to the actual measurement and setting. Combustion control system by the Belgian FIB company introduction of digestion and absorption of technology, when gas stable quality can to control the temperature difference between + 3°C or less.

The system has the function of constant air-fuel ratio, which can accurately control the atmosphere in each section of the furnace. At the same time, the combination of a variety of control means makes the pressure in the furnace controlled in the normal range, eliminating the oxidation of steel wire caused by the air inhaled in the furnace.

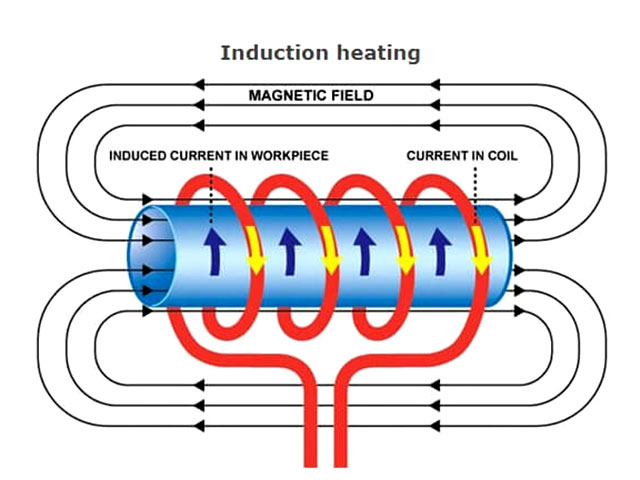

Induction heating

| Material | Alloy Steel Wire | ||||

|---|---|---|---|---|---|

| Wire Diameter | Ø0.9~2.6mm | Ø0.9~2.5mm | |||

| Number of Wires | 56/60, double-sided control | 36, A/B double sides control | |||

| Application | Copper-plated wire annealing heating | Bead wire tempering heat treatment | |||

| Heating temperature | 550°C | 450°C | |||

| Inductor | Multi-turn inductor series and parallel | ||||

| Heating DV value | 75mm.m/min | 500mm.m/min | |||

| Type | Continuous heating | ||||

| Dimensions | (W)1200×(L)10000×(H)1200 | (W)1000×(L)18000×(H)1200 | |||

| Power parameters | |||||

| Rated output power | 100kW | 200kW | 300kW | ||

| Output frequency range | 1-30kHz | ||||

| Power adjustment range | 10 to 100% stepless adjustment | ||||

| Cooling water flow | > 1.7m3/h, <35°C, industrial pure water | > 3m3/h, <35°C, industrial pure water | > 5m3/h, <35°C, industrial pure water | ||

| Power Dimensions | (W)1200×(L)700×(H)2000 | (W)1200×(L)800×(H)2000 | |||

| Dimensions | (W)1200×(L)10000×(H)1200 | (W)1000×(L)18000×(H)1200 | |||

Take-Up Machine

Vertical Spindle Spider Type Take-Up Machine

| Material | High Carbon Wire, carbon content 0.7~0.92% |

|---|---|

| Wire Diameter | Ø0.8 - Ø8.0 mm |

| Line Speed | DV: 45 - 65 mm • m/min |

| Drum Diameter | Ø450 mm, Ø650 mm, Ø760 mm |

| Applicable occasions | Heat treatment / Galvanizing / Phosphate |

Bobbin Type Take-Up Machine

| Material | High Carbon Wire, carbon content 0.7~0.92% |

|---|---|

| Wire Diameter | Ø0.8 - Ø3.5 mm |

| Line Speed | DV: 50 - 80 mm • m/min |

| Diameter of Capstan | Ø350 mm or Ø450 mm |

| Bobbin Type | Design Base Requirement |

| Arrangement | Back to Back or Line |

| Speed Control | Individual Control |

| Accumulation Time | Max 3 min |

| Application | Brass Coating / Galvanizing |