Dear Customers, Suppliers and Friends!

Our office will be closed from February 14th to 22nd in observance of Chinese Lunar New Year. We will resume back to work on February 23rd, 2026.

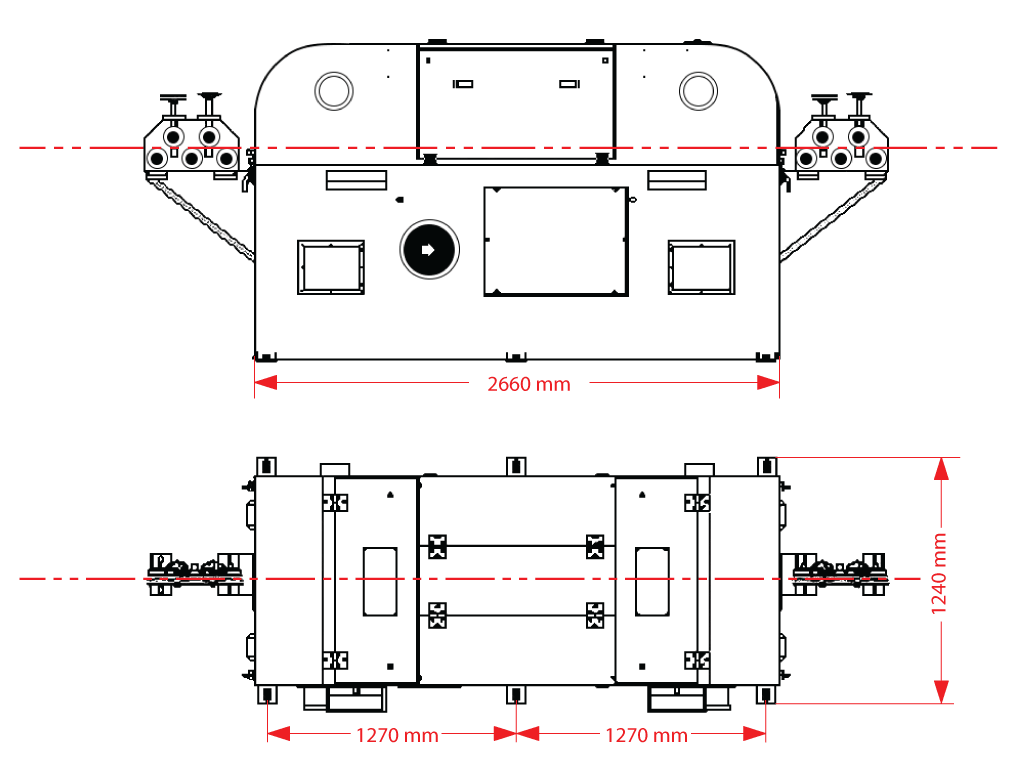

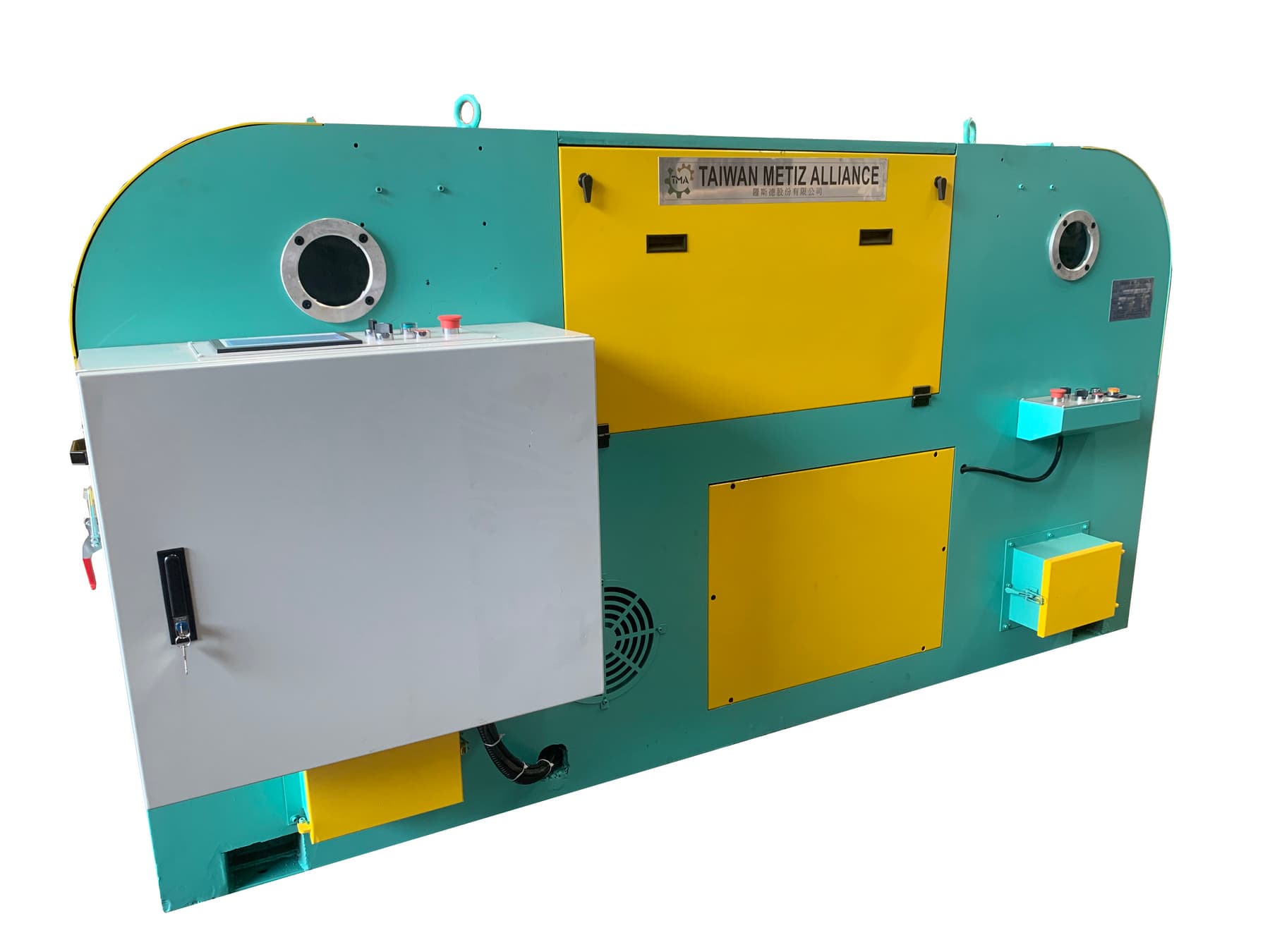

MECHANICAL WIRE DESCALING MACHINE

ABRASIVE BELT DESCALING MACHINE RG-8

The abrasive belt descaling machine frame employs a long square box structure as its foundational element. This equipment consists of a spindle, rotary disc, power drive unit, straightener, protective cover, and vacuum cleaner. The operational principle involves mounting a belt onto the turntable, enabling both revolution and rotation. The belt's linear speed reaches up to 15m/s, and it remains consistently close to the wire rod surface. This proximity is ensured by adjusting the eccentric shaft, which accomplishes tasks such as belt tensioning, releasing, belt loading/unloading, and wire rod threading. Additionally, modifying the tension of the sand belt is achievable through adjustments to the eccentric shaft lever spring.

The primary drive employs an 11kW frequency conversion motor connected to the spindle through a triangular belt. The turntable is bolted to the main shaft, facilitating maintenance and disassembly. The machine operates under PLC program control, communicating with the host machine, and can also switch to a separate control mode. The machine effectively eliminates rust from the steel wire surface through belt grinding, meeting all coating requirements. The abrasive belt utilized is either an imported zirconium corundum belt or a ceramic belt.

| Wire range | Ø5.5 mm - Ø10 mm |

| Working speed | 2 m/sec |

| Abrasive belt line speed | 15 m/secк |

| Abrasive belt quantity | 2 |

| Main motor power | 11 kW |

| Abrasive belt dimension | width 300 mm × length 1100 mm |

| Abrasive belt particle material | ceramics or Zircon corundum |

| Control system | PLC program control and host computer control |