WIRE PROCESSING EQUIPMENT

WIRE PROCESSING EQUIPMENT PRE-TREATMENT DRY DRAWING LINE EQUIPMENT FOR WIRE CLEANING SHOT BLAST MACHINE FOR CONTINUOUS WIRE CLEANING EQUIPMENT FOR WIRE POINTING EQUIPMENT FOR MECHANICAL DESCALING WIRE HEAT TREATMENT LINE

PRE-TREATMENT DRY DRAWING LINE

Pre-Treatment Line Application

The pre-treatment dry drawing line is mainly used for steel wire surface pre-treatment, such as removing rust, removing oxide skin, electrolyzed phosphating, borax and so on, to provide smooth and available steel wire for the follow-up process.

Equipment Advantages

- Brightening of the wire surface, no damage to the surface of the wire.

- Low operating cost, high efficiency and energy-saving.

- Beautiful construction, simple and safe to operate and maintain.

- European and American advanced technology.

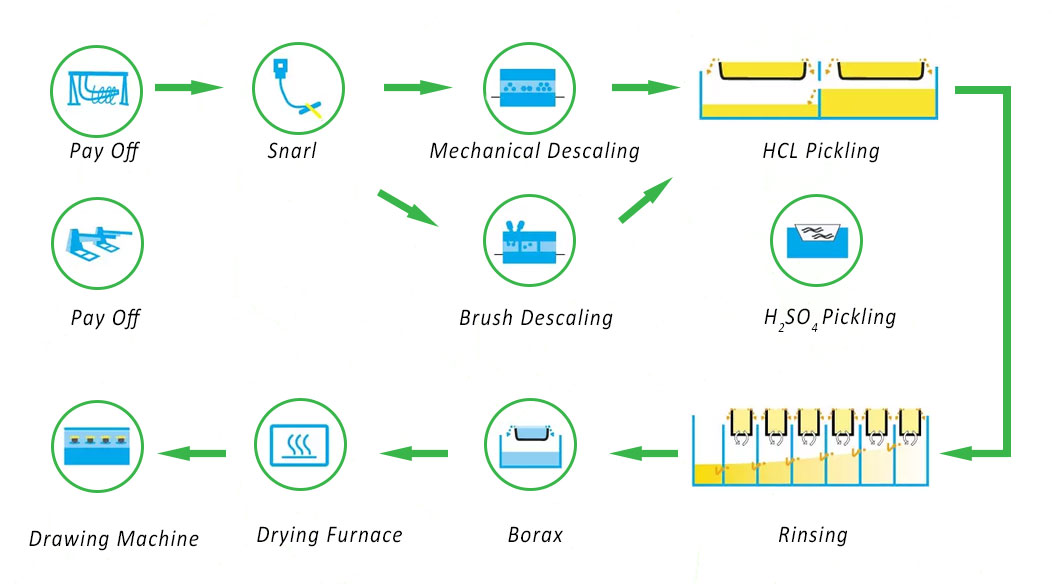

Process Step

The above process step is only for reference. We can design and manufacture the most suitable production line according to customers' requirements.

Technical Parameters

| Material | Carbon content 0.05 - 1.0% |

|---|---|

| Pay-off type | No need to stop when replacing, C-hook type with snarl / C-hook with wire entangle stop device |

| Wire diameter | Ø4 - 10 mm |

| Wire number | 1 / 2 / multiple |

| Line speed | ≈120 m/min |

| Descaling method | Mechanical scale brusher – 8 descaling wheels in 2 groups / Brusher |

| Surface cleaning | Chemical cleaning / Electrolytic pickling |

| Acid pickling | H2SO4 + Electrical / HCl + Steam |

| Boraxing type | On-line continuous |

| Wire-drawing machine type | straight line wire drawing, the first process is automatic wire accumulating drum |

| Take-up type | Coiler take up machine, adjustable circle vector |

Information required for the proposal

Which information is needed to make a proposal?

- Wire material.

- Diameter range.

- Wire numbers.

- Coating weight.

- Capacity.

- Pay-off and take-up method: spool/bobbin, spindle, spider / other.

For detailed information on the components included in the Pre-treatment dry drawing line, see the page SURFACE TREATMENT LINES COMPONENTS