WIRE PLATING EQUIPMENT

PROFESSIONAL WIRE PICKLING AND PHOSPHATING EQUIPMENT

We focus on line surface treatment solutions and can guarantee high-class quality, integrity, great service, and sustainable management for our clients.

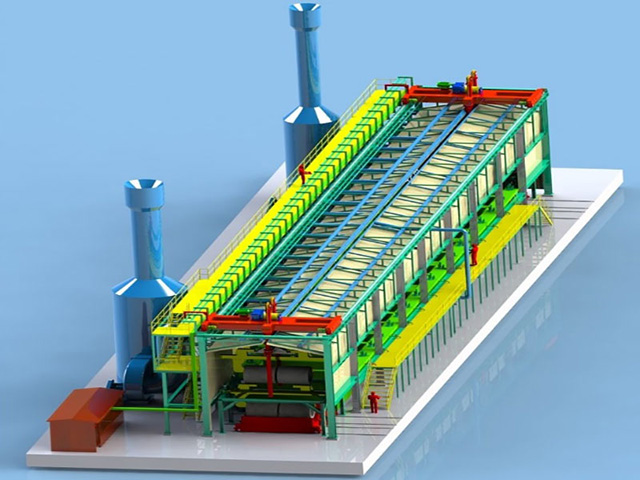

Equipment as a whole

Closed compartment material: FRP/PP

Description: The operating side and the maintenance side are designed with a transparent viewing window and a maintenance access door.

Configuration instructions: The main components of the equipment manipulator: the main steel structure, the reducer motor, the drive, the cable, and the sensing device are all designed outside the compartment.

Wire coil feeding

Configuration instructions: The wire roll feed enters from one side and is designed to be semi-automatic or automatic.

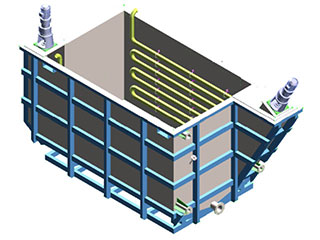

Wire Pickling tank

Optional material for the tank: PP/FRP

Configuration description: The large arc angle R is designed at the right angle of the trough body, and the bottom is designed as a slanting bottom. The vibration device, circulating agitation and heating device are additional.

OXALIC ACID / TABLE

Optional material for the tank: PP/FRP

Configuration instructions: The large arc R angle is designed at the right angle of the trough body, and the bottom is designed with a slant bottom.

PHOSPHATING

Optional material for the tank: Q235/SUS304/SUS316L

Configuration instructions: The bottom of the tank is a cone bottom, with optional vibration, automatic filtration system and automatic dosing device.

Saponification

Optional material for the tank: Q235/SUS304/SUS316L

Configuration instructions: Designed with a slanting bottom, the optional grooved diagonal design mechanical stirring device.

Reel unloading

Configuration instructions: The rail conveyor is equipped to cut the material, and the distribution frame and the wire rod rotation function are selected to facilitate the subsequent drawing process.

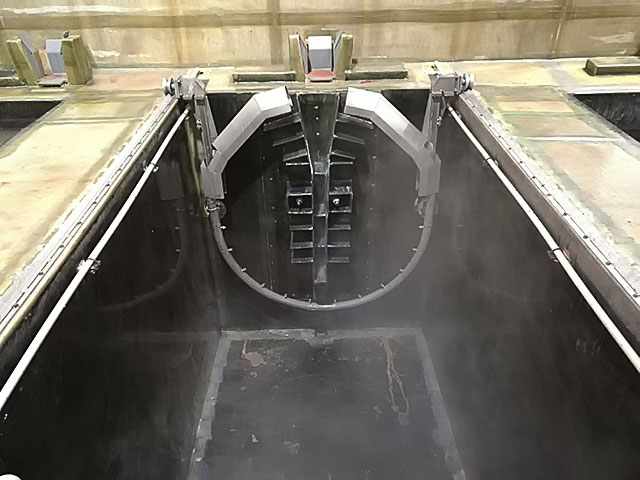

High pressure water washing tank

High-pressure water spray, internal spray + external spray + top spray. The sprayed water is recycled to save costs. The mechanism is installed outside the compartment to avoid corrosion, easy maintenance and low failure rate.

Track furnishing

Pedal material: FRP; door and window material: PVC

Each slot is provided with a transparent view window with a maintenance check door next to the important slot. Workers operate in a comfortable environment.

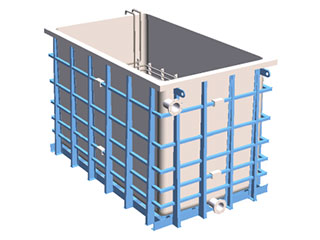

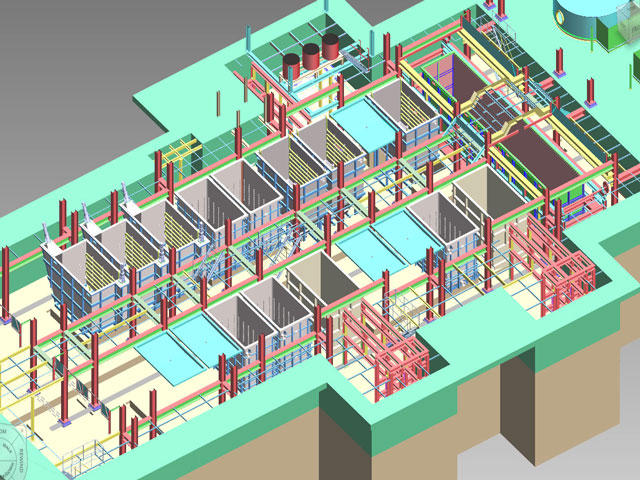

Outer tank

Configuration instructions: The drainage ditch/collection well is designed around the tank body. The pipelines are classified and arranged in layers. The daily inspection and maintenance are convenient for the workers and the 5S management is orderly.

Main control room

Configuration instructions: The equipment power control room is placed in a centralized position, equipped with independent compartments + air conditioning thermostat to ensure that the electrical components are in a stable working state for a long time.

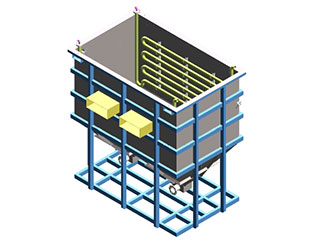

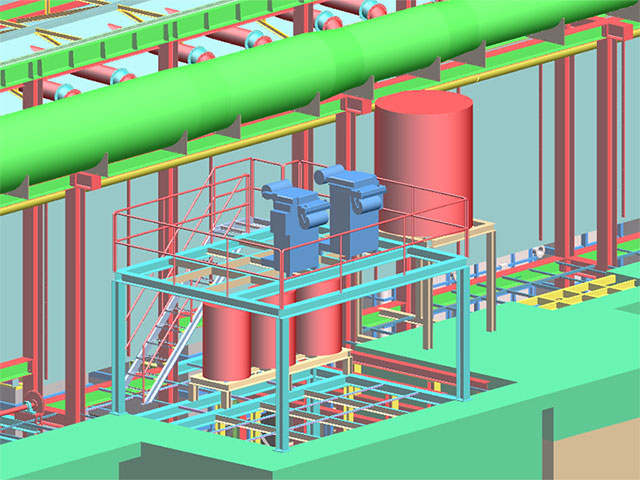

Phosphating slag filter press

Type: high efficiency precision filter paper

Main function: The filter press and the phosphating main tank form a cycle, process the phosphating sludge on-line, reduce the shutdown of the artificial tank to clean the sludge, reduce the labor intensity of the workers, improve the equipment utilization rate, improve the phosphating quality, and save the phosphating solution.

Hydrochloric acid storage tank

Main materials are: PE / FRP

The main function: temporary storage of new and old hydrochloric acid. Can clean the main tank to replace hydrochloric acid without stopping the machine, improve the service life of hydrochloric acid. It is safe and reliable, reduces pollution and reduces costs.

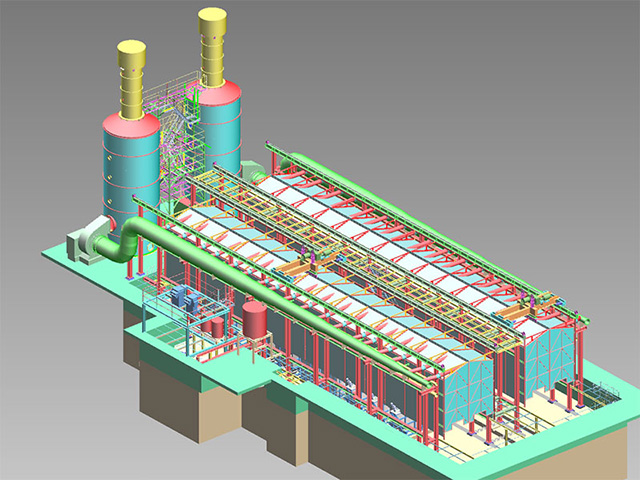

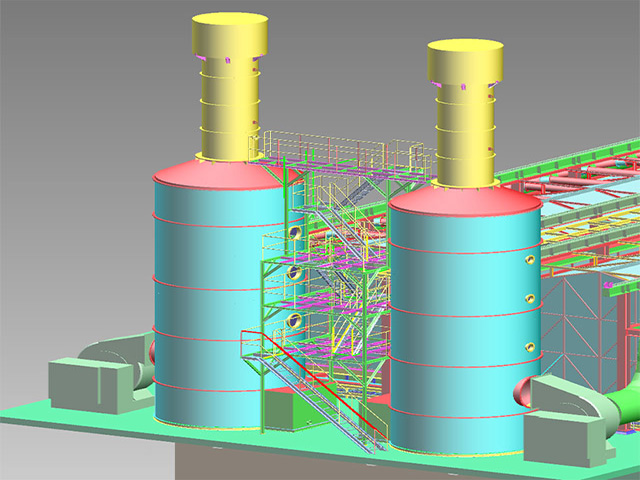

Exhaust gas treatment tower

The main materials are: FRP/PP.

Spreader

Material: iron plate outsourcing FRP/iron plate/stainless steel plate

3D simulation design

Sectional structure

Peripherals

Processing tank