WIRE PLATING EQUIPMENT

WIRE COPPER PLATING EQUIPMENT BRASS PLATING LINE STEEL WIRE HOT DIP GALVANIZING PROCESS LINE ELECTROLYTIC GALVANIZING LINE FOR STEEL WIRE HOT-DIP ZINC-ALUMINUM WIRE COATING LINE WIRE SURFACE TREATMENT LINES COMPONENTS

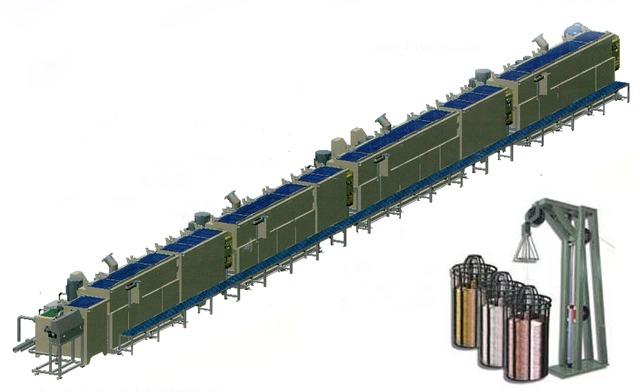

WIRE COPPER PLATING EQUIPMENT

Equipment for wire copper plating and galvanizing is used for the application of zinc, copper and other coating on the wire used in the manufacture of metal products, nails, etc. The line is a sequence of baths, with appropriate solutions, chemicals. Several parallel wire filaments of the same diameter are drawn on the surface of the galvanizing bath, made of polypropylene (on each of there is an electric motor) continuously and at a predetermined speed.

Type of equipment for electroplating the surface of the wire:

- Equipment for wire galvanizing.

- Equipment for wire copper plating.

- Equipment for wire nickel plating.

- Equipment for wire tin plating.

- Equipment for wire silvering.

- Equipment for the production of tinned wire, wire for electrodes.

Technological scheme of wire electroplating

| 01 | Feeding |

| 02 | Removing rust |

| 03 | Flushing (cutting knives) |

| 04 | Electrolytic degreasing |

| 05 | Flushing (cutting knives) |

| 06 | Etching |

| 07 | Flushing (cutting knives) |

| 08 | Plating |

| 09 | Flushing (cutting knives) |

| 10 | Rinsing in hot water |

| 11 | Drying (cutting knives)x 2 pcs. |

| 12 | Reeling in coils |

| Parameters of the Blanks | Size |

|---|---|

| Wire | Ø8.0 mm |

| Ø0.8-2.6 mm | |

| Microsize Ø0.1-1.2 mm | |

| Wire electrodes | |

| Rod | 20х150 mm |

| Sheet metal | thickness: 50 mm |

| width of reeling in coils: 400 mm |

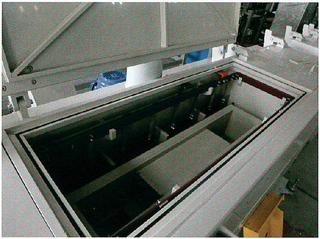

Electrolytic degreasing Bath

Electrolytic etching Bath

Wire transmission Wheel

Technical description and specification of equipment for wire copper plating and galvanizing:

- Suitable for brief wire treatments.

- Fully automated process.

- The ability to control the database management.

- Control of the processing time.

- Automatic adjustment of wire drawing speed.

- Galvanic baths are made of acid-resistant polypropylene.

- Working speed: 800 m / min.

- Working temperature: 70°C

- Stability in operation.

- Good thermal insulation, fast heating.

- Lines are available for treating the surface of rods, pipes and sheet metal.