HOT FORGING EQUIPMENT FOR FASTENERS, PARTS AND HARDWARE

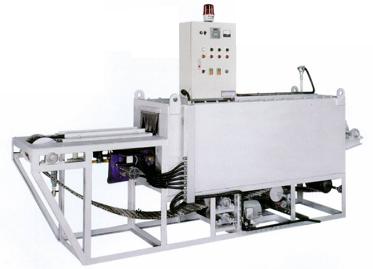

CONVEYOR GAS / ELECTRIC FURNACE FOR DIE FORGING

Equipment peculiarities

- Fast heating, low gas consumption, efficiency and practicality in use.

- Heat-resistant chain conveyor was produced in Japan, 4mm, 5mm

- Max. diameter of refractory body.

- 4 mm: 8 hours per day, warranty service - 1 year (by the most conservative estimate).

- 5 mm: 8 hours per day, warranty service - 2 years (by the most conservative estimate).

- Heating elements: copper and aluminum Alloy.

Specifications

| Power supply | The length of the heating area, M | The width of the conveyor, mm | Wire diameter, mm | Preheating time, hour | Drive, HP | Furnace temperature, ° C |

|---|---|---|---|---|---|---|

| Gas | 2 | 200 | Ø5.0-Ø5.0 | 1 | 1 | 800 |

| Gas | 2.3 | 200 | Ø5.0-Ø5.0 | 1 | 1 | 800 |

| Electricity | 6 | 400 | Ø3.0-Ø4.0 | 2 | 1 | 700 |

| Electricity | 8 | 400 | Ø3.0-Ø4.0 | 2 | 1 | 700 |

| Electricity | 10 | 500 | Ø3.0-Ø4.0 | 2 | 1 | 700 |

| Electricity | 12 | 500 | Ø3.0-Ø4.0 | 2 | 1 | 700 |

AUTOMATIC MACHINE FOR STAINLESS STEEL RODS CUTTING

Equipment peculiarities

- Suitable for cutting steel round rods.

- Automatic clamping, feeding, positioning and cutting tools.

- A solid structure with perfect system of lubricating fluid supply for long service life and mass production.

Specifications

| Type | Pressure, T | Frequency of strokes | Drive | Feeding speed, m / min | Air pressure 1/20 kW | Body | Parameters of the feeder | ||

|---|---|---|---|---|---|---|---|---|---|

| Stroke / min | Length mm | Body | Oil supply | L×W×H, mm | |||||

| RGF-320C | 50 | 70 | 40 | 3HP(4P) | - | 45 | 4 | 800×700×1100 | 6500×1520×1050 |

| RGF-320I | 50 | 60 | 40 | 3HP(4P) | - | 45 | 5-6 | 110×850×1600 | 6500×1520×1050 |

| RGF-380I | 90 | 60 | 60 | 10HP(6P) | - | 45 | 5-6 | 1300×1000×1950 | 6500×2000×1150 |

| RGF-450I | 120 | 50 | 65 | 15HP(6P) | - | 45 | 5-6 | 1500×1000×1950 | 6500×2200×1250 |

| RGF-550I | 160 | 50 | 75 | 20HP(6P) | - | 40 | 6-7 | 1800×1300×2200 | 6500×2200×1250 |

| RGF-600I | 200 | 40 | 85 | 25HP(6P) | 0.4(4P) | 40 | 6-7 | 1900×1380×2350 | 6500×2200×1250 |

| RGF-750I | 300 | 40 | 100 | 40HP(6P) | 0.4(4P) | 40 | 6-7 | 2000×1560×2400 | 6500×2200×1250 |

| RGF-1000I | 400 | 40 | 120 | 50HP(6P) | 0.4(4P) | 40 | 6-7 | 2600×1700×2500 | 6500×2200×1250 |