EQUIPMENT FOR CLEANING SURFACE OF METAL FROM RUST, OIL AND DIRT

HYDROCARBON SOLVENTS FOR PARTS CLEANING

We are developing washing machines for vacuum hydrocarbon ultrasonic cleaning. The composition of AQ-SOLVENT solvents for cleaning parts has been developed and perfected over 30 years. We are ready to offer a water-soluble cleaning agents, inhibitors, means for displacing oil with water etc.

With the experience and knowledge of the mechanisms of hydrocarbon washing machines we offer choice of a large range of solvents, the most suitable for a particular type of cleaning, including operating and application instructions, technical support for the maintenance of the equipment.

AQ-SOLVENT is based on isoparaffin hydrocarbon of high degree of purification. Solvents are not contain unsaturated hydrocarbons, aromatic additives or impurities such as sulfur and chlorine. Isoparaffin hydrocarbon is not harmful to humans and the environment, it is also widely used as additive in cosmetics. Isoparaffin hydrocarbon serves as a main component, cleaning agent, has ideal physical properties and unlike simple flammable paraffinic hydrocarbon has a relatively high ignition temperature and final boiling point.

| SOLVENT RGF | SOLVENT RGX | SOLVENT RG-71 | SOLVENT RG-30 | |

|---|---|---|---|---|

| Main component | isoparaffin | isoparaffin | isoparaffin | isoparaffin |

| Appearance | colorless | colorless | colorless | colorless |

| Density | 0.75 | 0.748 | 0.751 | 0.725 |

| Flash point | 48°C | 41°C | 71°C | 24°C |

| Ignition temperature | 368°C and higher | 200°C and higher | 220°C and higher | 200°C and higher |

| Boiling point | 176°C | 153°C | 188°C | 130°C |

| Boiling end | 180°C | 180°C | 213°C | 165°C |

| Classification | Mineral oil #2 | Mineral oil #2 | Mineral oil #3 | Mineral oil #2 |

Solvents vaporation

Solvents RG/RGF/RGX Series are best suited for degreasing and removal of fine particles from the surface of electronic tools, communication devices, automotive parts, household appliances.

High-efficiency hydrocarbon solvent AQ-RAX Series

AQ-RAX SERIES hydrocarbon solvent is suitable for contaminated parts degreasing, removing oil used in industrial mechanisms operating at high pressure. AQ-RAX SERIES solvent has been specifically designed for the removal of solid organic compounds, flux, paraffin, wax, resin, tar.

AQ-RAX solvent was specially developed with the addition of glycol-based oil hydrocarbon, it is ideal for degreasing and removing of remaining flux and ion-containing coat. Its solvent power is very high, however, it can be easily disposed using distiller.

AQ-RAX #100 azeotropic solution with the addition of glycol to highly refined paraffin, which can be recycled by distiller. Ideal for printed circuit boards and solder components cleaning from flux.

AQ-RAX #200 is processed similarly as the AQ-RAX #100. Widely used for Ultrasonic cleaning and steam cleaning.

Comparison of dissolving power

|  |

| Regular hydrocarbon solvent | AQ-RAX Series solvent |

| Product name | Function | Properties | Application methods | concentration | Package |

|---|---|---|---|---|---|

| AQ-RAX #100 | cleaning from flux | group 4, Mineral oil #2, Flash point 41°C | immersion cleaning, ultrasonic cleaning | sheer | 18L 200L |

| AQ-RAX #200 | group 4, Mineral oil #3, Flash point 73°C |

High-efficiency hydrocarbon solvent AQ-SOLVENT GR/SP SERIES

We are a supplier of series of safe solvents for cleaning and removing of hard-soluble pollutants, such as adhesives, paint, scale. Our solvent is based on isoparaffin hydrocarbon with high cleaning properties and does not contain benzene, xylene, toluene, aromatic additives that are dangerous to the environment. AQ-SOLVENT GR / SP SERIES solvents are ideal for precision cleaning, including degreasing and removing elements and parts with submicron dimensions.

Functional classification:

- removal of flux;

- cleaning of metal molds (incl. Plastic mold);

- removal of paint and ink;

- removal rust and scale;

- cleaning of soil containing ions, fingerprints removal.

AQ-SOLVENT RGR-1000 is used for electronic and precision parts cleaning. Best suited for cleaning ion-containing coat and remove fingerprints. Water-soluble. After solvent treatment of the parts rinsing and drying operations are allowed.

AQ-SOLVENT RSP is used for adhesives, paints, inks and resin removal. Suitable for recycling and reuse.

AQ-SOLVENT RSP-20D and AQ-SOLVENT RSP-30 have good penetrating ability, easily remove adhesive substances from blanks surface in a short time, the adhesive softens and removes dirt, paint, ink and resin.

AQ-SOLVENT RSP-100E removes dirt, adhesive, paint, ink and resin.

| Product name | Function | Properties | Application methods | concentration | Package |

|---|---|---|---|---|---|

| RGR-1000 | cleaning of soil containing ions, fingerprints removal | group 4, Mineral oil #3, Flash point 89°C | immersion cleaning, ultrasonic cleaning | sheer | 18L 200L |

| RSP | alternate solvent | group 4, Mineral oil #2, Flash point 34°C | immersion cleaning, ultrasonic cleaning | ||

| RSP-20D | group 4, Mineral oil #2, Flash point 23°C | ||||

| RSP-30 | group 4, Mineral oil #2, Flash point 23°C | ||||

| RSP-100E | group 4, Mineral oil #2, Flash point 55°C | immersion cleaning, ultrasonic cleaning |

Hydrocarbon agent for water displacement AQ-SOLVENT RZ SERIES

Hydrocarbon agent for water displacement has a high rates of cleaning the blank surface from inorganic fine particles.

| Product name | Main component | Flash point | Classification | Protocol on Pollutant Release and Transfer Registers |

|---|---|---|---|---|

| SOLVENT RZ-G3 | isoparaffin hydrocarbon | 46°C | Mineral oil #2 | not applicable |

| SOLVENT RZ-SP | isoparaffin hydrocarbon | 83°C | Mineral oil #3 | not applicable |

| SOLVENT RZ-71 | paraffin hydrocarbon | 71°C | Mineral oil #3 | not applicable |

Displacement characteristics

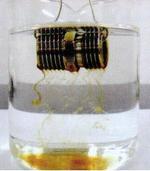

Immerse the wire mesh in water for filling the cells with water and then immerse the same mesh in hydrocarbon agent for displacing water to observe process and nature of water movement in the cells of the wire mesh in the solution, to check the speed with which water is separated from the mesh and the coefficient of water displacement.

| Product name | Correlation of water drops remainder after 3 sec | Correlation of water drops remainder after 5 sec |  |

|---|---|---|---|

| AQ-SOLVENT RZ-G3 | remainder about 10% | No remainder | |

| Product of other Company N | remainder about 30% | remainder about 10% |

Production service life

There are many commercial products with excellent characteristics of water displacement, but fast losing their characteristics. For this reason it is very important to pay attention to the service life of acquired products.

| Product name | Liquid separation AFTER 1 min | Liquid separation AFTER 5 min |

|---|---|---|

| AQ-SOLVENT RZ-G3 | About 30% of water separated | Complete separation, clear water |

| Product of other Company N | After shaking no significant differences | Interdeterminate boundary, turbid water |

|  |  | |

| RZ-G3 | Product of other Company N | ||

|---|---|---|---|

| 1 min | 5 min | 1 min | 5 min |

Test Method

Add water (20 cc) to water displacement agent (80 cc) in the test tube. Shake it strongly for 5 min to make the components – water and water displacement agent start to move and mix.

After mixing leave the test tube and observe the process of separation of water and water displacement agent into two layers, noting the color of the fluid - clean clear water or drumly.

If the water after separation become transparent and there is a clear boundary between the layers of liquid, such products have good quality (without defects).