NON-WASTE CLEANING EQUIPMENT

Hydrocarbon solution gas recovery equipment RECR

This equipment makes the gases to the liquid state and restores dissolved in hydrocarbon gas solution formed as a result of vacuum washer. Exhaust gas discharged through the vacuum pump can be recovered.

For the equipment installation you need only lead gas outlet tubes. The equipment is easily combined and can be used or installed in-line with any washing equipment.

The equipment is easy to use, does not require replacement of consumables such as filters, dimensions are small enough.

The equipment has vertical design, only 29 cm in width and can be installed anywhere.

| Exhaust volume | Solution | Group 4, mineral oil №2, crude oil №3, standard cleaning hydrocarbon solution . | ||

|---|---|---|---|---|

| Standard volume of leaking gas 3.5m3/min. (max. 5.5 m3/ min.) | ||||

| Standard temperature of treated gas 50°C (max. 90°C) | ||||

| Two-stage system of gas recovery | Primary | Open-type gas catcher (with demister) | ||

| Secondary | Close-type water-cooling heat exchanger | |||

| Fluid separation system | Recovery system by gravity separation | |||

| Tools | Recovered gas indicator, exhaust gas indicator, coolant temperature indicator, meter (level) for separated water. | |||

| Container for recovered solution | 18 litres plastic container | |||

| Equipment appearance | Dimensions | 550х290х1200 mm | Weight | 50 kg |

| Body | colored enclosure | Legs | installing bolts х 4 pcs. | |

| Fittings | Gas feeding | 50 А | Gas emission | 50 А |

| Cooling liquid feeding | 15 А, ridged dispersing nozzle | Cooling liquid emission | 15 А, ridged dispersing nozzle | |

| Integrated mechanism | Cooling liquid volume | 2 l/min. (recommended temperature 20-25°C) | ||

Rapid Heating Oil Removal Equipment R-DRY-M

R-DRY-M evaporates B-1 SERIES oil so fast that does not leave spots on metal surface. All treatment process takes a few seconds. Continuous processing is available. The equipment uses an induction heating system, which heats only press group parts. Unlike electric heating induction heating is not harmful to the environment and do not bother air-conditioning facilities.

Equipment Application

- hardware running parts cleaning;

- automatic equipment parts;

- plates;

- engine bodies etc.

Equipment Features

- standard equipment dimensions: 1300 × 1100 × 1200 mm

- capacity: 5 kW

- conveyor dimensions: length 1000 × width 60 mm

- linear speed: 30-120 mm/sec

- pass line: 1000 mm

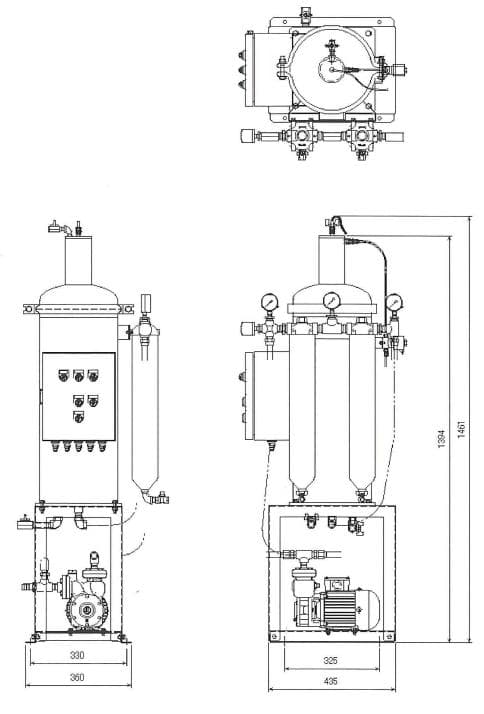

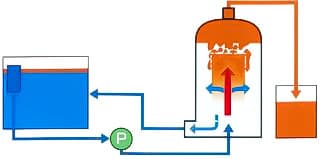

Equipment for oil and water separation RRS-20AQ

Equipment is ideal for oil and liquid separation in water-soluble environment. Fractional filter special design helps to degrease solutions. Filter fiber captures particles of oil, and has good acceptance rate. Filter acts as a separator of water and oil, collects fine particles of emulsified oil, transforming them into bigger size fractions which can be easily removed from the solution surface.

| Item | Specifications |

|---|---|

| Performance | 1000/1200 L/h (50/60 Hz) |

| Max. pressure | 0.5 МPa |

| capacity | 3 phases, alternating current 200V, 50/60 Hz (alternating current 220V, 60Hz) |

| Power input | 0.4 kW |

| Solution temperature | max. 80°C |

| Solution volume | 50 litre |

| Equipment dimensions | 530х580х1465 mm |

| Net weight | 90 kg |

| Filter brand | PW320-10.PW320-12.PC614-01Z |

| Audible warning | Filter blockage, pump overload |

Water purification technology

Degree of water purification

AFTER - oil concentration 30 mg/liter

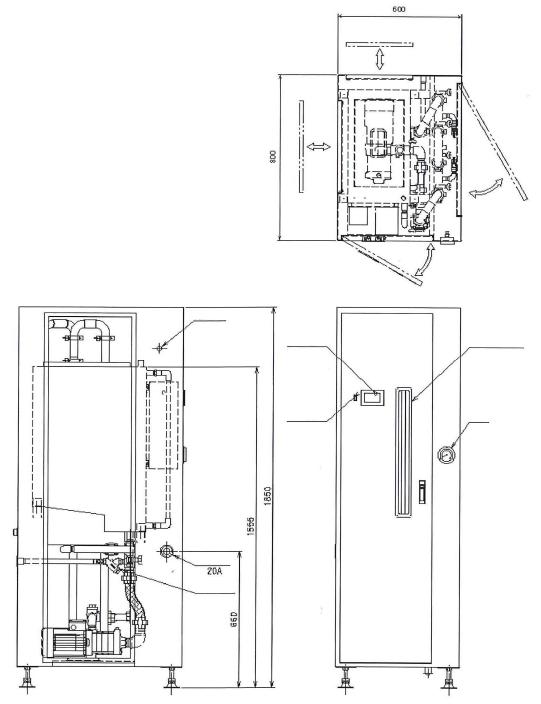

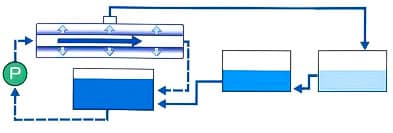

Wastewater cleaning equipment RS-200AQ-16

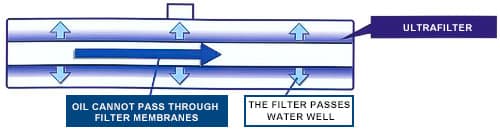

The equipment is ideal for closed-cycle production. Cleaning and restoration of waste water is caused by UV filter technology. UV filter includes a permeable membrane for water filtration. Filter membrane does not pass oil and other foreign bodies.

Technical specifications of equipment

| Item | Specifications |

|---|---|

| Performance | 200 L/h |

| Max. pressure | 0.5 МPa |

| Capacity | 3 phases, alternating current 200V, 50/60 Hz |

| Power input | 0.4 kW |

| Solution temperature | max. 60°C |

| Solution volume | 40 litre |

| Equipment dimensions | 600х800х1800 mm |

| Net weight | 90 kg |

| Filter brand | 100000MW (set of 16 pcs) |

| Audible warning | fall of water level |

Water purification technology

Degree of water treatment

AFTER - oil concentration 3 mg/liter

Vacuum drying oven RUD-1

This equipment reduces exhaust emissions to the environment, including emissions from industrial waste water after completion of drying and washing, that is a serious approach to environmental protection. AUD-1 Series vacuum drying chamber provides a quick drying of products and a low percentage of electricity consumption.

The equipment is able to evaporate remaining oil particles from the surface of products, technological equipment, as well as machine parts. Energy-saving, high quality drying and evaporating capacity factor are very important characteristics of the equipment. The equipment is ideal for heat air-conditioning systems exchangers drying.

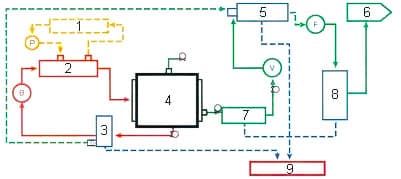

- Oil heating.

- Oil cooler.

- Hot air catch tank.

- Vacuum drying oven .

- Catch tank for air bleed.

- Air bleed.

- Vacuum collector.

- Exhaust-cleaning equipment.

- Bath for cleaned used oil.