COLD HEADING & COLD FORMING MACHINERY

COLD HEADING MACHINES FOR BOLT

Equipment for DIN 931 bolts heading

| Product Name | RBF10B3SL | RBF13B3SL | RBF17B3SL | RBF19B3SL | RBF24B3SL | |

|---|---|---|---|---|---|---|

DIN 931  | М6x30 | М8x35 | М10x40 | М12x45 | М14x50 | М16x55 |

| М6x35 | М8x40 | М10x45 | М12x50 | М14x55 | М16x60 | |

| М6x40 | М8x45 | М10x50 | М12x55 | М14x60 | М16x65 | |

| М6x45 | М8x50 | М10x55 | М12x60 | М14x65 | М16x70 | |

| М6x50 | М8x55 | М10x60 | М12x65 | М14x70 | М16x75 | |

| М6x55 | М8x60 | М10x65 | М12x70 | М14x75 | М16x80 | |

| М6x60 | М8x65 | М10x70 | М12x75 | М14x80 | М16x90 | |

| М8x70 | М10x75 | М12x80 | М14x90 | М16x100 | ||

| М8x75 | М10x80 | М12x90 | М14x100 | М16x110 | ||

| М8x80 | М10x85 | М12x100 | М14x110 | М16x120 | ||

| М10x90 | М12x110 | М14x120 | М16x130 | |||

| М10x100 | М12x120 | М14x130 | М16x140 | |||

| М14x140 | ||||||

Equipment for DIN 933 bolts heading

| Product Name | RBF10B3S | RBF13B3S | RBF17B3S | RBF19B3S | RBF24B3S | |

|---|---|---|---|---|---|---|

DIN 933  | М6x12 | М8x16 | М10x20 | М12x25 | М14x30 | М16x35 |

| М6x16 | М8x20 | М10x25 | М12x30 | М14x35 | М16x40 | |

| М6x20 | М8x25 | М10x30 | М12x35 | М14x40 | М16x45 | |

| М6x25 | М8x30 | М10x35 | М12x40 | М14x45 | М16x50 | |

| М6x30 | М8x35 | М10x40 | М12x45 | М14x50 | М16x55 | |

| М8x40 | М10x45 | М12x50 | М14x55 | М16x60 | ||

| М8x45 | М10x50 | М12x55 | М14x60 | |||

| М8x50 | М10x55 | М12x60 | ||||

| М8x55 | М10x60 | |||||

| М8x60 | ||||||

Equipment for DIN 6921 bolts heading

| Product Name | RBF10B4SL | RBF13B4SL | RBF17B4SL | RBF19B4SL | RBF24B4SL | |

|---|---|---|---|---|---|---|

DIN 6921  | М6×12 | М8×16 | М10×20 | М12×25 | М14×30 | М16×35 |

| М6×16 | М8×20 | М10×25 | М12×30 | М14×35 | М16×40 | |

| М6×20 | М8×25 | М10×30 | М12×35 | М14×40 | М16×45 | |

| М6×25 | М8×30 | М10×35 | М12×40 | М14×45 | М16×50 | |

| М6×30 | М8×35 | М10×40 | М12×45 | М14×50 | М16×55 | |

| М6×35 | М8×40 | М10×45 | М12×50 | М14×55 | М16×60 | |

| М6×40 | М8×45 | М10×50 | М12×55 | М14×60 | М16×65 | |

| М6×45 | М8×50 | М10×55 | М12×60 | М14×65 | М16×70 | |

| М6×50 | М8×60 | М10×60 | М12×65 | М14×70 | М16×75 | |

| М6×55 | М8×70 | М10×65 | М12×70 | М14×75 | М16×80 | |

| М6×60 | М8×75 | М10×70 | М12×75 | М14×80 | М16×90 | |

| М8×80 | М10×75 | М12×80 | М14×90 | М16×100 | ||

| М10×80 | М12×90 | М14×100 | М16×110 | |||

| М10×90 | М12×100 | М14×110 | М16×120 | |||

| М10×100 | М12×110 | М14×120 | М16×130 | |||

| М12×120 | М14×130 | М16×140 | ||||

| М14×140 | ||||||

The equipment for the heading of bolts

| Product Name | RBF19B4SL | Product Name | RBF24B4S | Product Name | RBF19B5S |

|---|---|---|---|---|---|

Hexagon bolt with flange. | М12×1.25×115 | Hexagon bolt with flange and pointed tip. | М14×1.5×50 | Wheel bolt. | М12×1.25×55 |

| М14×1.5×90 | |||||

|  |  |

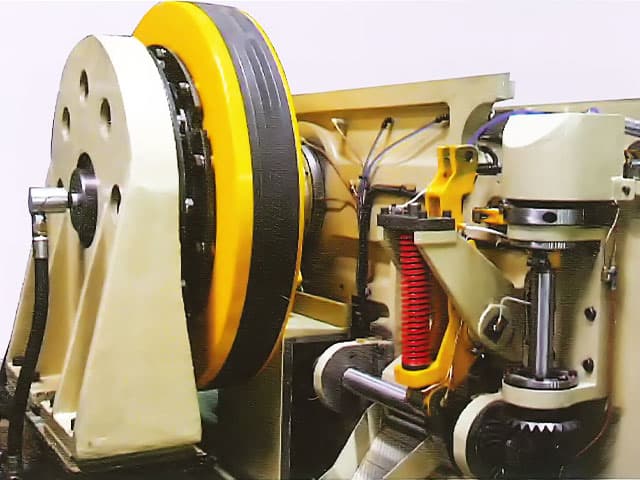

PECULIARITIES OF BOLTS PRODUCTION EQUIPMENT CONFIGURATION

Machines peculiarities in comparison with machines of other companies

| Mehanism | RG design material | Design, material of ordinary companies |

| Basic frame Material | FCD-60 alloyed ductile iron (Japan) It has a certificate of quality of the United States in Southeast Asia. | Cast iron 20-25 is cheaper and lower-strength that worse provides strength and stability of the machine during its operation |

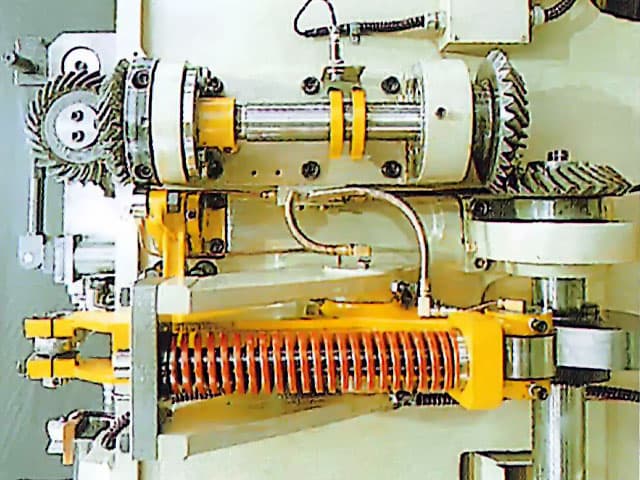

| Crankshaft | It was manufactured using a new process and technology homogenized nitriding and polishing | It was made by cheaper process of homogenization. |

| Crankshaft socket | Made from a special aluminum alloy.Patent. | Made of bronze (less durable and fast-wearing) |

| The hollow cutting knife | Special Jern Yao patent, easily removed | Complex process of shooting |

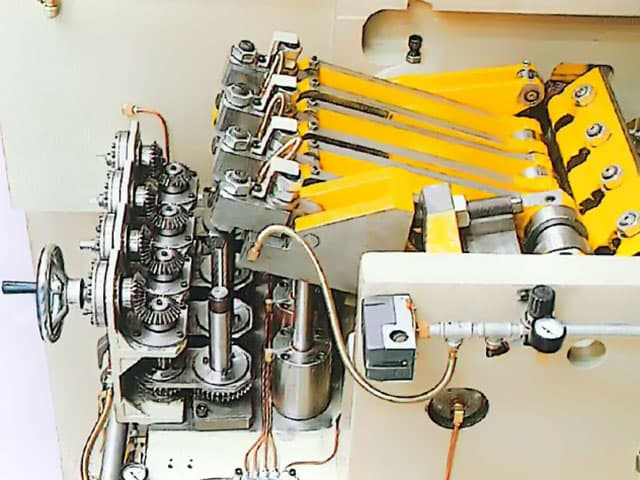

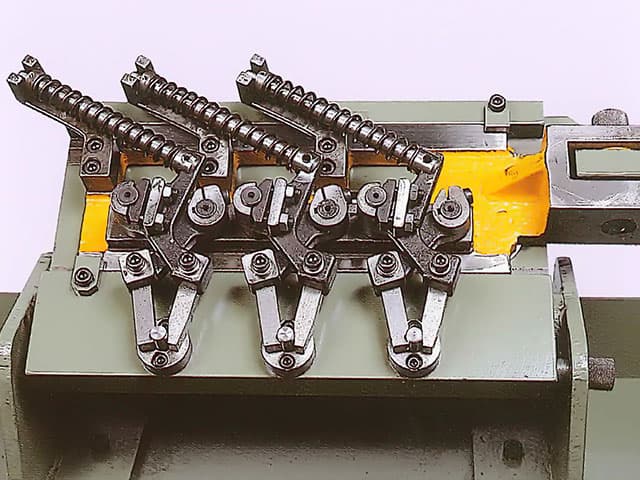

| Punch ejecting mechanism | Cam-roller type specially designed for high precision | Cam-roller type standard type |

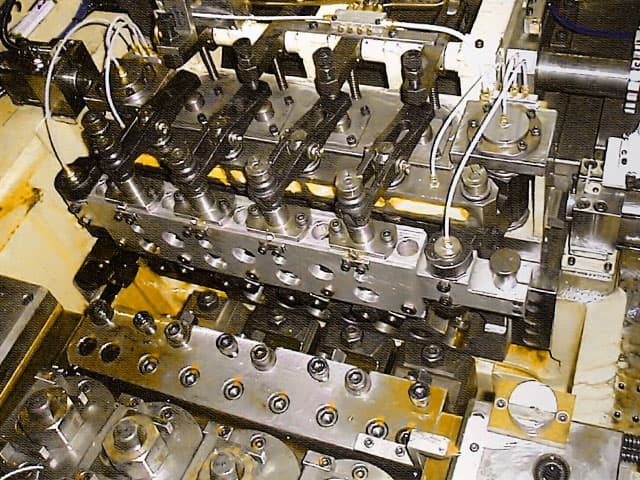

| Punch holder | Hardened carbide SKD-11 | Without hardening |

| Serviceability of punch ejecting mechanism | Easy to maintain without taking out of the machine. | Must be removed from the machine for maintenance. Idle time of machine. |

| Internal self-examination of the machine | Automatic analysis of the static and dynamic stress | Without this feature. |

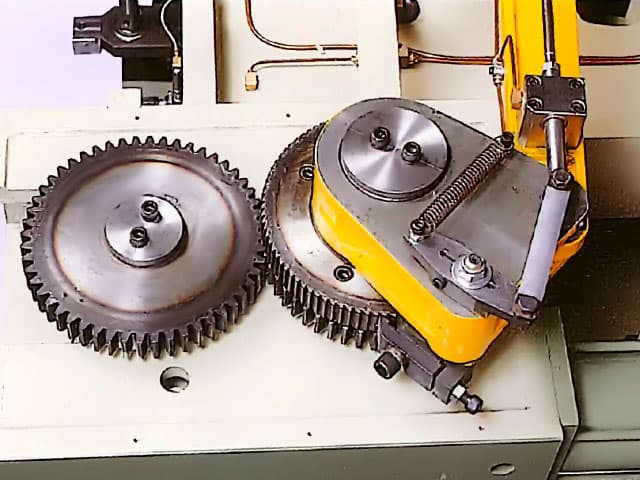

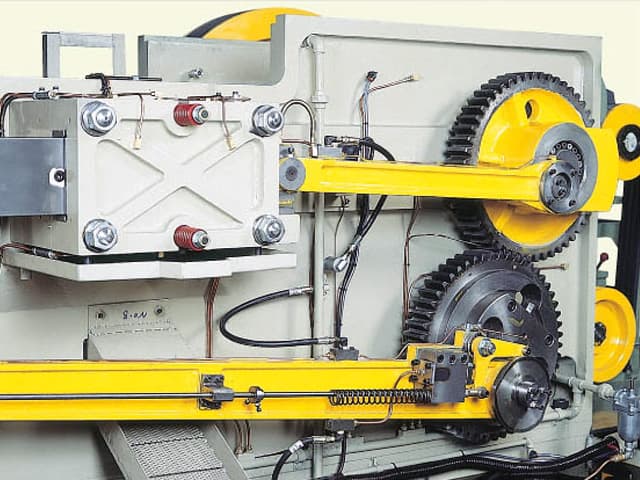

| Gear | Polished. Japan Metal. | The gear is made in China |

| Distribution of lube oil | The increased size of the pipeline, promotes good and uniform distribution of oil | The standard system |

| The accuracy of the machine in the manufacture of products | The accuracy of movement within the main ejector of 50mm with accuracy of less than 0.02 mm | Inaccuracy more than 0.03 mm |

| Tool | In the company there is a special team for tools and technological process design. It reduces the number of tool units for the production of different products on the same machine. | The company does not have such team for designing tools and processes. |

| Spare parts | The stock of spare parts in the storage of the factory, which ensures fast delivery, if necessary | Not the total volume of stock, long time to order and manufacturing in China. |

| The cost of spare parts | One of the lowest on the market | The high cost of parts |

| Electrical system | Imported, CE standard | Standard |

| Electrical system design | Design and assembly of manufactured exclusively in Jern Yao factory | All is done by subcontractors |

| Main slide block | With copper socket for machine tools 24B Series and more | Without it. |

| Electrical parts and assembly | The design, import and assembly are made exclusively by Jern Yao | Partial use of subcontractors |

| Machine operating | Easy to operate and work, saving a lot of time with help of quick-change mechanism (which is a great advantage in the production of several types of products under its small numbers) | Standard on the market Without these functions |

Standard configuration of cold heading equipment for bolts and nuts production

| Full name of the equipment components | Q-ty, units / Specification |

|---|---|

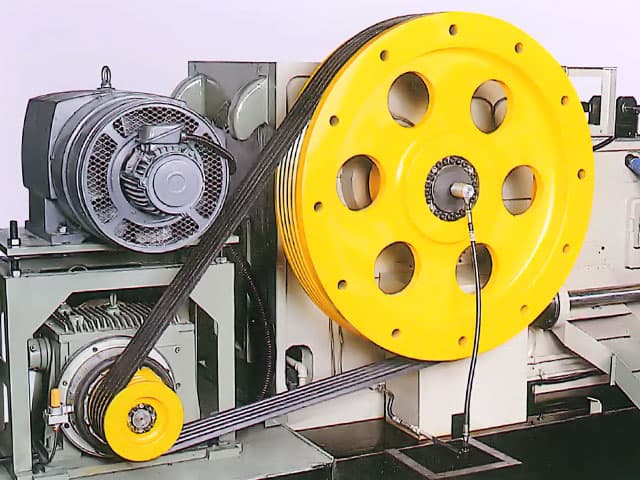

| AC engine (4/6 poles) with 6-speed transmission or AC engine (6-pole) with inverter. | 1 pcs. |

| Electric control cabinet with PLC (Programmable logic controllers), made by Mitsubishi, Japan | 1 pcs. |

| Pneumatic disc brake system | 1 pcs. |

| Wire unwinding device | 1 pcs. |

| Model-S | Standard roll-over stand |

| Model-B | Standard roll-over stand with straightening wire mechanism |

| Model-A | horizontal Hydraulic juggie |

| Model-D | horizontal Hydraulic juggie |

| Model-P | horizontal Hydraulic juggie |

| Model-T | horizontal Hydraulic juggie |

| The tank with cooling oil | 1 pcs. |

| Cleaning system from oil mist | 1 pcs. |

| Roll-over 180 ° gear | 1 pcs. |

| Spare parts | standard |

| Working platform | 1 pcs. |

| Operating instructions with drawings of spare parts, electrical circuits and equipment foundations | 1 pcs. |

Malfunction detection system

- Insufficient air pressure sensor

- Blank feeding error detector

- Blanks lack detector

- Circuit error detector

- Punch ejection mechanism error sensor

- Engine overload sensor (oil, cooling fans)

- Oil level sensor

- Pneumatic clutch error sensor

- Pneumatic clutch error sensor with manual control

- Inverter error sensor

- Screen for monitoring the value of forces error sensor (if the monitoring device is supplied with the equipment)

Taiwan Metiz Alliance equipment for bolts cold heading for the past 20 years is delivered and used on the biggest factories of the world, products are supplied to many companies-sellers of hardware and fasteners for the automotive companies such as Toyota, Honda, companies of aerospace industry and many other companies producing fasteners. The equipment has a special certificate for the whole cast and the base frame, and it is always a feature of stability (vibration) and durability.

Advantages of Taiwan Metiz Alliance is that our equipment for the production of bolts has the best performance on price/quality compatibility. All buyers have long to check and verify from personal experience that the quality of Taiwan Metiz Alliance equipment is top class.

Also worth noting that the prices offered by Taiwanese manufacturers are much lower than the prices offered by the American, Italian and Japanese manufacturers. In the world market of fasteners Taiwan Metiz Alliance has established itself as the most reliable supplier of equipment for the production of bolts with competitive prices. The geography of our deliveries has about 35 countries around the world, including such countries as the US, Japan, Germany, Italy, France, Russia, Belarus, China, India, Malaysia, Thailand and many others.

TECHNICAL FEATURES OF THE EQUIPMENT FOR BOLTS COLD PRODUCTION

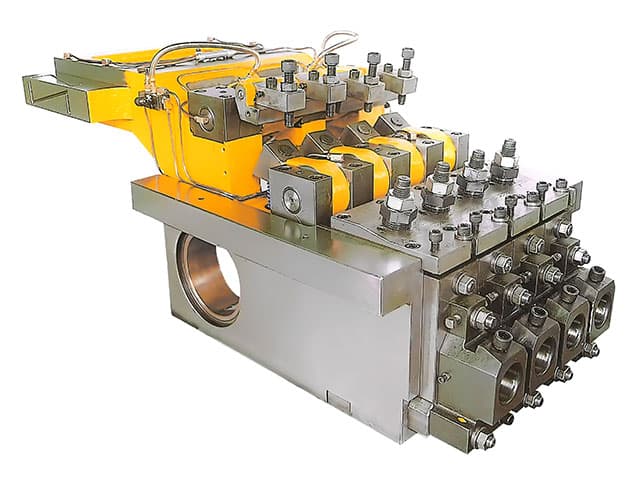

The frame provides absolute stability and a straight forward process of heading. Made of cast iron with nodular graphite grade JIS FCD 55, which ensures its durability.Holders of the matrix are made of stainless steel grade FCD 70 are arranged parallel to each other and can be adjusted independently.

The rollers provide blanks feeding for small size bolts heading.

Hand wheel control allows setting the length of the KO

Pneumatic type of SACMA blank feeding provides high-speed and stable process of heading.

Punch ejecting mechanism can be installed on request.

Motorised correct mechanism provides stable operation of wire rod fixing (diameter greater than Ø18 mm).

The mechanism of power failure by S-CAM system is controlled by crankshaft horizontally.

Transmitting clicks provide a secure blanks grip

Stop of bolts cold heading equipment occurs automatically in the case of:

- fault,

- the need to clean the blank.

Pneumatic clutch and brake system maintain flywheel in torsion movement.

Taiwan Metiz Alliance provides equipment with 2, 3, 4, 5, 6, 7 positional forging stations for bolts production of different shape, diameter and length. The equipment supports three modes of blanks feeding, including spring, synchronous and pneumatic modes, fitted with pneumatic clutch and brake, speed change is controlled by an inverter.

The equipment produces bolts with diameter M3, M4, M5, M6, M8, M10, M12, M16, M20, M22, M24, M27, M30, up to 355 mm.

These products are manufactured on equipment with 2, 3, 4 positional forging stations

- The diameter of bolts: M4-M30

- The length of the screws: 10 mm - 300 mm

These products are produced on equipment with 4, 5 th, 6 th, 7 th positional forging stations

- The diameter of bolts: M3-M30

- The length of the screws: 8 mm - 360 mm

EQUIPMENT FOR BOLTS PRODUCTION SPECIFICATIONS

| RBF Series 2-Die 2 Blow Bolt Former 2Ph2U | Specification of products:

|

| RBF Series 3-Die 3 Blow Bolt Former 3Ph3U | Specification of products:

|

| RBF Series 4-Die 4 Blow Bolt Former 4Ph4U | Specification of products:

|

| RBF Series Multi-Station Bolt Former 5P, 6P, 7P | Specification of products:

|

Workshop with equipment for the production of bolts by the method of cold heading