PACKAGING EQUIPMENT FOR FASTENERS, METAL HARDWARE AND PARTS

GENERAL INFORMATION ON THE TECHNOLOGY OF PACKAGING OF HARDWARE, FASTENERS AND PARTS

Taiwan Metiz Alliance is engaged in design and manufacture of automated lines for packing screws, nuts, studs, steel and iron nails, rivets and other fasteners "turnkey".

Today, thanks to the efforts, experience and professional skills, the company has received many patents for its products.

The company's specialists are constantly engaged in innovation and development of new products.

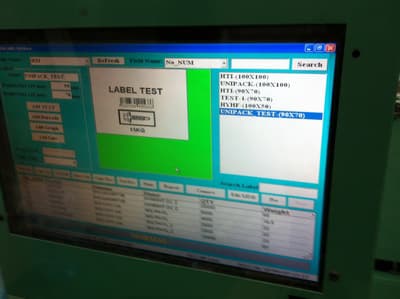

At the same time, the company is investing a lot of money and put a lot of time designing and developing numerical control, computer integration and the creation of user-friendly operator interface to meet modern technical requirements.

Technological process of automatic packing of fasteners into carton

Cardboard

Auto carton forming

Screw auto packaging

Auto carton sealing

Computer printing / labeling

Auto palletizing

Auto stretch wrapping

Technological process of automatic packing of fasteners into boxes

Cardboard

Auto box forming

Screw auto packaging

Auto box sealing

Computer printing / labeling

Auto case packaging

Computer printing / labeling

Auto palletizing

Auto stretch wrapping

Packaging equipment configuration

The packing line includes the following equipment list:

- auto tipping and filling equipment;

- auto carton / box forming equipment;

- auto carton bagging equipment;

- auto carton/box/ electromagnetic paralleling packaging equipment or auto carton/box/bag fill-in type packaging equipment;

- auto box folding and sealing equipment;

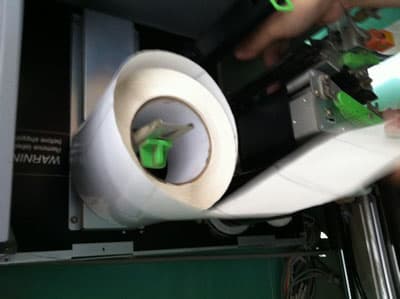

- auto box printing / labeling equipment;

- auto palletizing and stretch wrapping equipment;

- automated transport system;

- automated storage.

Packaging lines components

In the packaging equipment only high quality materials and parts are used to ensure its reliable operation.

The packaging lines mainly use imported components from leading world companies or components from well-known Taiwanese companies: servo motors and positioning sensors PANASONIC (Japan), programmable logic controller MITSUBISHI (Japan), safety sensors SICK (Germany), load cells TEDEA (Germany), control sensors SHAN HO (Taiwan), KOYO and NSK (Japan) bearings, control panel HMI PRO-FACE (Japan), electromagnetic contactors SCHNEIDER (Germany), SMC, CKD (Japan) and FESTO (Germany) cylinders, inverters TECO (Taiwan).

Power consumption of the packaging line

| Tipping and filling equipment | Forming equipment | Packaging equipment | Palletizing equipment | Wrapping equipment | Total power consumption |

|---|---|---|---|---|---|

| 6.6 kW | 7.04 kW | 27.28 kW | 13.2 kW | 3.52 kW | 57.64 kW |

Technological process of wrapping containers on wrapping equipment

Packing cases

Top-sheet stretch wrapping

Horizontal strapping

First stage vertical strapping

Second stage vertical strapping

Auto stretch wrapping

Appearance of the line for automatic packaging of fasteners and hardware

Completed projects of automatic packaging lines for bolts and nuts