CRUCIBLE FURNACE

Crucible furnace are used for melting of metals and alloys, and also for storage of all kinds of melts. Normally, crucible furnaces are available in fixed and tipping positions. Fixed crucible furnaces are suitable for melting metal and store it in a molten state, depending on the fill in special forms. Crucible furnaces are often used to pour metal from the furnace because of its inclination around its axis.

In crucible furnaces heating is performed using coils made of fechral wire which is wound on an alumina tube, and for this purpose may be used silicon carbide. Built-in heater core in the crucible furnace provides the opportunity to achieve higher temperature conditions during metals melting.

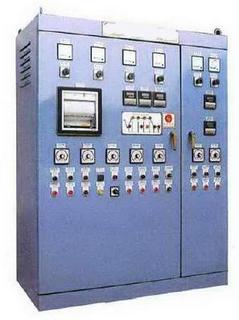

Management of crucible furnaces can be carried out through a dedicated electronic control unit, which makes regulations and temperature control. In order to reduce the inertia of the thermocouple control channel it is necessary to install ceramic straw with open junction.

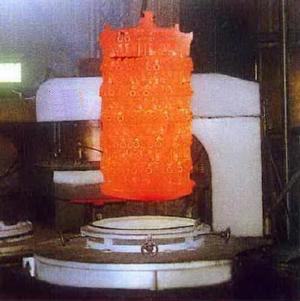

Gas crucible furnaces for carburizing and hardening

Crucible gas furnaces are ideal for small-scale production, carburizing and hardening parts of the automotive industry, motorcycles, bicycles, gears, hand tools and other metal parts.

Applicable gas - methanol, toluene

Specifications of gas crucible furnace for carburizing and hardening

| Model | Outside diameter x furnace height, mm | Diameter of the protective crucible x height, mm | Diameter x height of the support column, mm | power, kW |

|---|---|---|---|---|

| RG-829-1 | 1430х1450 | 500х1200 | 350х600 | 35 |

| RG-829-2 | 1530х1750 | 600х1500 | 450х900 | 65 |

| RG-829-3 | 1880х2050 | 750х1800 | 600х1200 | 90 |

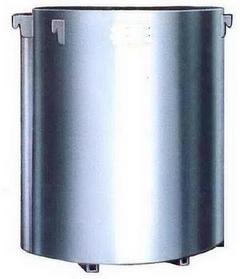

Hardening (oil) tank

SPECIFICATIONS of the Hardening (oil) tank

| Model | Overall length x width of the tank, mm | Tank Diameter, mm | The inner diameter x height of the tank, mm | Tank capacity, L | power, kW |

|---|---|---|---|---|---|

| RG-830-1 | 2400х1950 | 1440 | 700х950 | 3200 | 10 |

| RG-830-2 | 2650х2440 | 1840 | 970х1200 | 5200 | 10 |

| RG-830-3 | 2650х2440 | 1840 | 970х1200 | 5200 | 10 |

Tank for washing and degreasing

Specifications of the tank for cleaning and degreasing

| Model | Outside diameter x height of the tank, mm | The inner diameter x height of the tank, mm | power, kW |

|---|---|---|---|

| RG-831-1 | 800х1000 | 500х800 | 15 |

| RG-831-2 | 1000х1220 | 600х1100 | 15 |

| RG-831-3 | 1000х1530 | 750х1400 | 15 |

Crucible furnace with hot blast

Technical characteristics of the furnace:

| Model | The outer diameter and height of the furnace, mm | The inner diameter and height of the furnace, mm | power, kW |

|---|---|---|---|

| RG-832-1 | 1330х1220 | 540х850 | 20 |

| RG-832-2 | 1430х1530 | 640х1150 | 30 |

| RG-832-3 | 1580х1830 | 790х1450 | 55 |

Crucible furnace with a maximum temperature of 900-1200 degrees is used for melting of tin, zinc, and their alloys. Heating in these furnaces is carried out by coils made of fechral wire.Construction of crucible furnace, in which the maximum temperature is equal to 1400 degrees, is used for smelting copper and various copper alloys. In order to heat must use the n-shaped silicon carbide heater, which is sure to set horizontally.

If you produce a high-temperature alloys using crucible furnaces special crucibles and disilicide, ie special heating elements should be applied. There is an opportunity to reload the crucible during melting without opening the lid. In comparison with other models of furnaces design of this furnace is very economical, because it uses a new high-performance lining materials made of high-temperature heaters that have heating elements with increased resource.

Crucible type annealing furnace RG-835

Technical specification of furnaces

| Model | The outer diameter x height, m/m | The size of the protective pot, m/m | Work tank size, m/m | Productivity, kg | power, кВт |

|---|---|---|---|---|---|

| RG-835-1 | 3474 x 2610 | 2750 x 2300 | 2600 x 1800 | 5000 ~ 6000 | 324 |

| RG-835-2 | 3474 x 3410 | 2750 x 3210 | 2600 x 2600 | 7000 ~ 9000 | 480 |

| RG-835-3 | 4074 x 3266 | 3350 x 2910 | 3150 x 2200 | 12000 ~ 14000 | 480 |

| RG-835-4 | 4924 x 3750 | 4000 x 2925 | 3500 x 2700 | 20000 | 772 |

| RG-835-5 | 5424 x 4550 | 4500 x 3725 | 4000 x 3500 | 30000 | 800 |