EQUIPMENT FOR CLEANING METAL SURFACES FROM DIRT, OIL AND RUST

VACUUM ULTRASONIC CLEANING MACHINES

We offer a wide range of equipment for parts cleaning ideal for use with our products - solvents and cleaning agents for rust removal and degreasing. Thus, buying our products and the equipment of our partners you can be confident in high quality of your purchase.

Washing machines technical specifications

- Quality assurance.

- Simplification of standard operations, ease of operation.

- Increase energy savings.

- Economical consumption of cleaning agents and solvents.

- The equipment does not harm the environment.

- Compact, space-saving equipment.

- Good compatibility with the production line, wide automation.

- Low waste substances and exhaust rate, waste-free production.

Simple design, high power, standard set of features and affordable price.

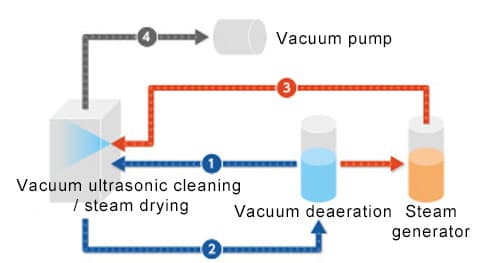

In the operation cleaning solutions are saturated with air bubbles. The formation of air bubbles is significantly reduced due to the ultrasonic cleaning. The exhaust gases are removed by distillation of the solution through the air separator, which greatly improves the process of ultrasonic cleaning.

The air separator is a set of outlets, it removes the smallest air bubbles, providing cleaning in vacuum environment. Thus, by addition of degreasing agents an effect of complex-shaped parts cleaning is achieved.

Finish parts cleaning and rinsing is made by products irrigation with steam coming from the steam generator. Thus the parts are subjected to heating with steam and immediately vacuum dried using a vacuum pump. Steam cleaning and vacuum drying systems are equipped with waste liquid recovery and distillation mechanism.

Standard washing machines RVN3/ RVN4sp series

| Item | Specifications |

|---|---|

| Square washing basket | 400×360×200 |

| Hexagon washing basket | Ø300×500 mm |

| Equipment dimensions | 4350×2100×2500 |

| Operational blank weight | 20 kg |

| Productivity of equipment | 5 min/basket |

| Distillator productivity | 100 L/h |

| Liquid volume | 370 L |

| Conveyor | Lift-and-carry type |

| Ultrasonic cleaning mechanism | 1200 V: 28 KHz ×2 pcs. |

| Power input | 25 kW |

| Air demand | 600 L/min. (0.45 МPa) |

| Cooling water | 40 L/min. (20°C) |

| Exhaust pipes | Ø100 mm |

Washing machines with 3 reservoirs RVN3 series

RVN3 washing machine with 3 reservoirs is ideal for mass-production.

Standard washing machines with 4 reservoirs RVN4sp series

CONCEPT VN4sp washing equipment with 4 reservoirs is ideal for mass production.

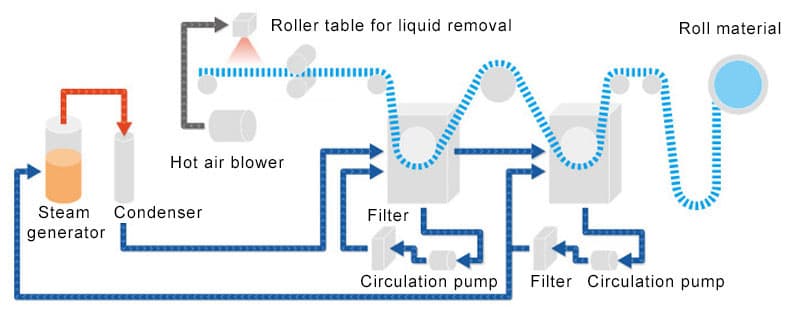

Vacuum washing machines for rinsing in hydrocarbon environment at high temperature CLEAN-D series

CLEAN-D washing equipment for cleaning in hydrocarbon environment at high temperature is ideal for mass production.

- High degree of cleaning agents solubility is achieved due to hydrocarbons heated up to 80-100°C

- Reducing of the time required for parts cleaning is achieved due to degreasing at high temperatures.

- Reducing of the time required for drying the parts is achieved through cleaning the parts at high temperature.

- Good solution filtration is achieved by reducing the surface tension of the liquid.

- Cleanliness of the surface after rinsing is achieved by irrigation and steam cleaning equipment.

- Cleaning and return to the system of used exhausts reduces washing solutions flow.

| Item | Specifications |

|---|---|

| Square washing basket | 300×400×200 mm |

| Rotary-type washing machine | 220×400 mm |

| Equipment dimensions | 1060×1800×1950 mm |

| Operational blank weight | 20 kg/cycle (max.) |

| Performance | 7 min/cycle (max.) |

| Regenerated liquid volume | 100 L/h |

| Liquid volume of baths for hot wash | 140 L |

| Liquid volume of baths for cold wash | 50 L |

| Ultrasonic cleaning mechanism | 1200 V: 28 KHz |

| Power density | 1 V/cm2 . 24 V/l |

| Conveyor | lifting type |

| Exhaust clearing system | 200 V (with heat-resisting ventilator) |

| Fire extinction system | Automatic spray СО2, 5 kg |

| Gas concentration counter | hydrocarbon gases detector |

| Power input | 20 kW (3phase 200V) |

| Air demand | 50 L/min. (0.4 МPa) |

| Cooling water | 20 L/min. (20°C) |

| Exhaust pipes | 6.5 м3/ min. (Ø100) |

1. Standby Mode

Compact miniature version of the equipment. In standby mode, before washing the washing liquid is heated up to 80°C temperature in vacuum environment. The washing liquid removes foreign bodies by filtration and cleans the equipment by gas regeneration.

2. Ultrasonic Cleaning

Advanced degreasing characteristics.. After vacuum environment creating, the hydrocarbon solution is fed at a high temperature. Ultrasonic cleaning is carried out in vacuum environment. Removal of foreign bodies is achieved by filtration. Improving of degreasing characteristics is achieved through high temperature of the solution and high density of ultrasonic waves. Immediate dissolution of viscous oils and fats occurs.

3. Steam Cleaning

Heavy steam cleaning process. After ultrasonic cleaning the used washing liquid is returned (distillated), and instead a large amount of purified steam solution is fed at high temperature, followed by rinsing. Efficiency of steam generation is 50% compared with the standard models, which maintains the output power.

4. Vacuum Drying

Waste-free clean resource-saving production not harming the environment. All used steam is cleaned and recycled after parts processing. Residual droplets of the solution in the wash bath are dried by evaporation in vacuum environment. Once the equipment goes into standby mode recovered purified washing liquid is fed and the whole cycle repeats.

Small-scale washing equipment with one reservoir TET-R series

By integrating a set of functions a high degree of cleaning is achieved.

- Vacuum ultrasonic cleaning.

- Steam cleaning.

- vacuum drying.

- distillation and regeneration.

| Item | Type-S | Type-L |

|---|---|---|

| Square washing basket | 250×280×200 mm | 300×400×200 mm |

| Rotary-type washing machine | 220×300 mm | 220×400 mm |

| Equipment dimensions | 900×1600×1950 mm | 1060×1800×1950 mm |

| Operational blank weight | 10 kg/cycle (max.) | 10 kg/cycle (max.) |

| Performance | 10 min/cycle (max.) | 10 min/cycle (max.) |

| Regenerated liquid volume | 40 L/h | 40 L/h |

| Liquid volume of baths for hot wash | 90 L | 140 L |

| Liquid volume of baths for cold wash | 35 L | 50 L |

| Ultrasonic cleaning mechanism | 600 V: 28 KHz | 1200 V: 28 KHz |

| Power density | 0.9 V/cm2 . 17 V/l | 1 V/cm2 . 24 V/l |

| Conveyor | lifting type | lifting type |

| Exhaust clearing system | 200 V (with heat-resisting ventilator) | 200 V (with heat-resisting ventilator) |

| Fire extinction system | Automatic spray СО2, 3 kg | Automatic spray СО2, 5 kg |

| Gas concentration counter | hydrocarbon gases detector | hydrocarbon gases detector |

| Power input | 13 kW (Ø3:200V) | 14 kW (Ø3:200V) |

| Air demand | 50 L/min. (0.4 МPa) | 50 L/min. (0.4 МPa) |

| Cooling water | 20 L/min. (20°C) | 20 L/min. (20°C) |

| Exhaust pipes | 6.5 м3/ min. (Ø100) | 6.5 м3/ min. (Ø100) |

- Vacuum ultrasonic cleaning. After de-aeration process the washing liquid in vacuum tank is changed. After that vacuum ultrasonic cleaning starts.

- Switching between processes. Cleaning fluid is automatically drained while the blank is installed in machine, and it switches the mode to the next.

- Steam cleaning. Cleaning solution used in vacuum ultrasonic cleaning can be completely removed by parts irrigation with hot steam supplied from the steam generator.

- Vacuum drying. High-speed vacuum drying is carried out in oxygen-free environments by use of self-generating heat and steam cleaning.

Equipment for water-soluble components rinsing, displacement and vacuum drying

This equipment is ideal for parts cleaning for water-soluble oils and drying without the formation of rust and spots on the parts surface.

Widely used for cleaning:

- Tools,

- Production accessories,

- Polished and other treated surface, for which any residual water or other water-soluble components are not recommended.

Tank 1 Water-soluble flushing. Cleaning and degreasing of synthetic water-soluble oils of industrial mechanisms are carried out by alkaline agents.

Tank 2 Flushing in water and rinsing. Flushing in water and rinsing with a small amount of corrosion inhibitor.

Tank 3 Water-based components displacement. Displacement agents separate aqueous components, thereby protecting blanks from corrosion.

Tank 4 Cleaning in hydrocarbon environment. Cleaning of separated components is performed in hydrocarbon solution.

Tank 5 Steam cleaning/vacuum drying. Parts cleaning by hydrocarbon steam and high-speed vacuum drying prevents the formation of spots on the surface of the parts.

Equipment for vacuum rinsing

This equipment is ideal for cleaning parts with surface defects caused by air and stuck together details. Cleaning is performed in water-soluble environment.

Widely used for cleaning:

- parts with surface defects caused by air;

- stuck together parts;

- cleaning is performed in water-soluble environment.

Equipment for cleaning small electronic parts

Widely used for cleaning:

- lead frames;

- contacts;

- limit switch parts.

Equipment for cleaning of accumulator boxes, condensator and fuel induction system parts

Widely used for cleaning:

- accumulator boxes,

- condensator parts,

- parts of fuel injection system.

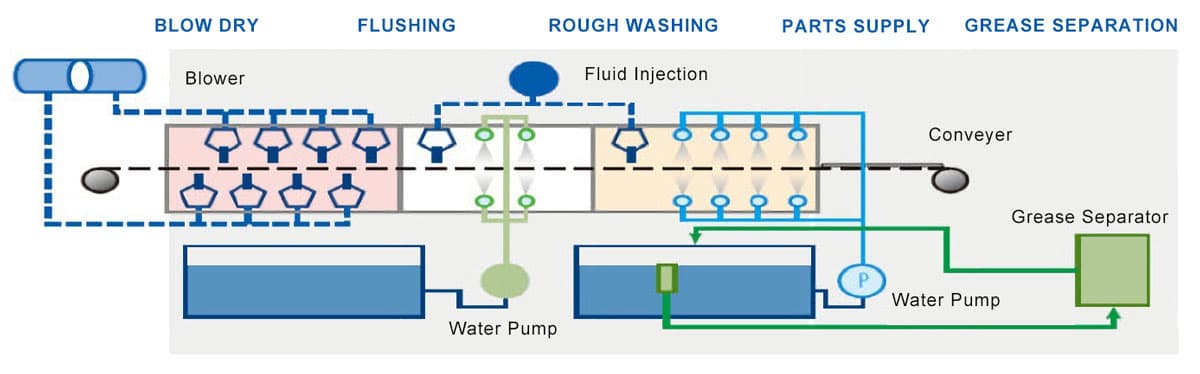

Equipment for parts cleaning by irrigation

Widely used for cleaning:

- Non-operating (back) TV covering

- TV bottom, foundation.