COLD FORMING EQUIPMENT FOR SELF TAPPING SCREWS AND RIVETS

BOLT FORMER NUT FORMER PARTS FORMER OPEN DIE REHEADER COMPLEX FASTENERS FORMER SELF TAPPERS AND SCREWS FORMER MICRO SCREWS FORMER HEADING OF LONG PRODUCTS STUD FORMER RIVET HEADING WASHERS PRESS COLD-HEADING OF HOLLOW PRODUCTS

SELF TAPPING SCREWS PRODUCTION

EQUIPMENT FOR DRILLS FORMATION ON SELF TAPPING SCREWS

Self-tapping screws with a drill tip differ from other types of self-tapping screws by the presence of a tip in the form of a drill and a head in the form of a press washer or a cone. There is no need to drill holes to use such parts. The drill bit is capable of making a threaded rod pass like a drill. The shape of the head allows you to tightly close the attachment point and secure it securely.

A self-tapping screw with a press washer with a drill for metal is often used to connect metal profiles to each other and to attach thin sheets of metal and polymer materials to metal frames up to 2 mm thick without pre-drilling holes in the materials.

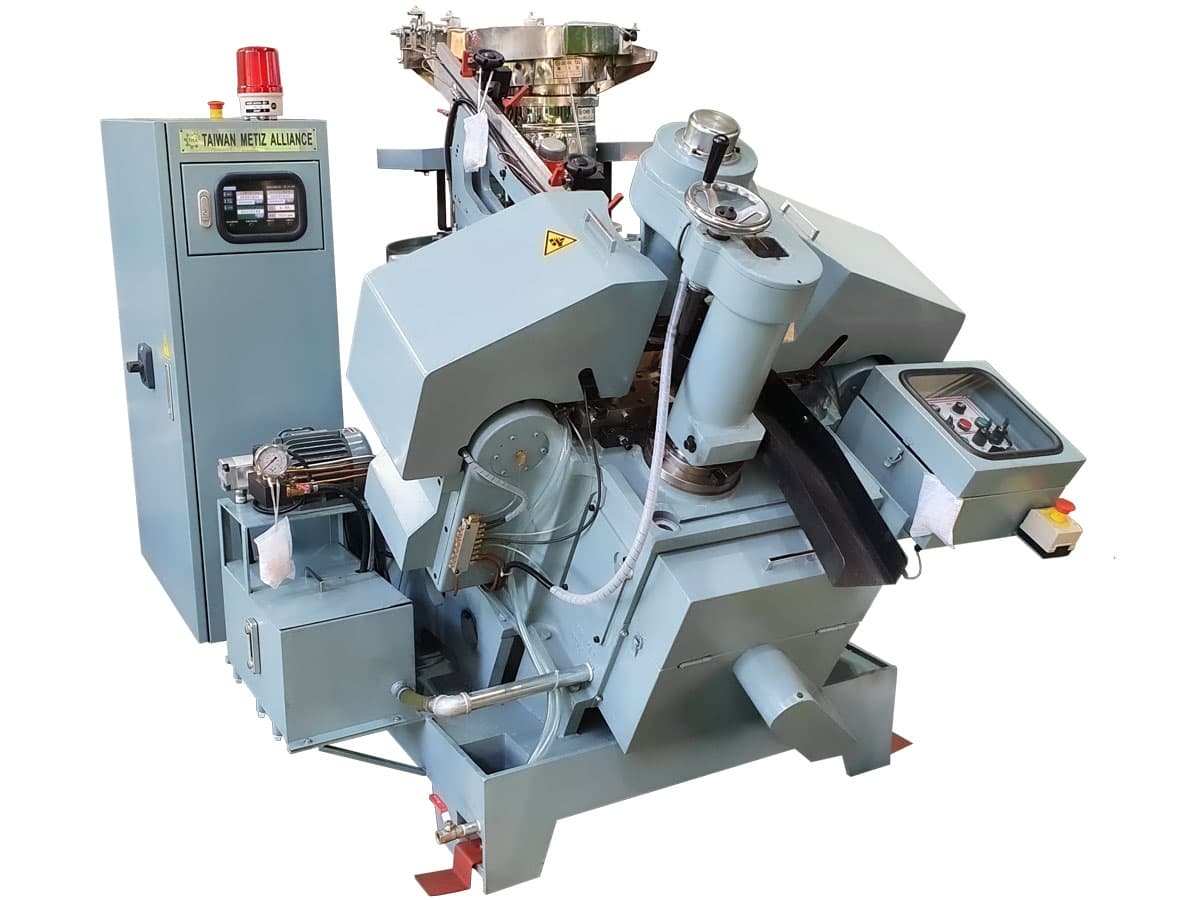

Self Drill Screw Forming Machine RG-235

| Model | Max. Blank Diameter | Max. Blank Lenght | Machine Speed, pcs./min. | Die Size | Main Motor | Speed Regulation | Control System | Blank Feeding | Machine Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RG-235 | 2.8-6.3 mm | 9.15-220 mm | 100~500 | 25 × 102 × 127~1405 | 10HP / 7.5 kW / 6 Phase | INVERTER | PLC | Bowl Vibrator, Ø712 mm | 200 × 240 × 200 | 2520 | 2845 |

Self Drill Screw Forming Machine RG14 Series

Self-Drilling Forming Machine Features

- The equipment produces self tapping screws and forms drills.

- Specification: high speed, stability and durability.

- Material: equipment manufactures self tapping screws of stainless steel SUS304, carbon steel SAE1018.

- Components: the machine can be equipped with a rack for feeding blanks. This saves space and improve operation efficiency. Rack can be combined together with the cold heading and thjred-rolling equipment for the production and the formation of the self-tappers pens.

- Set of tools.

Specifications of equipment for drills formation

| Model | RG14-125AN | RG14-127AN | RG14-203AN |

|---|---|---|---|

| RG14-125AN-2S | RG14-125AN-2S | RG14-203AN-2S | |

| The main motor | 7.5 hp x 6 phases | 7.5 hp x 6 phases | 7.5 hp x 6 phases |

| Inverter | 5.5 kW | 11 kW | 11 kW |

| Stress | 220 V /380V x 3 phases | 220 V /380V x 3 phases | 220 V /380V x 3 phases |

| Principle of operation | Pneumatic | Pneumatic | Pneumatic |

| The controller | NC DC24 V | NC DC24 V | NC DC24 V |

| Automatic systems | Automatic fault logging system | Automatic fault logging system | Automatic fault logging system |

| Vibrating feeder | Ø620 mm | Ø720 mm | Ø850 mm |

| Performance | 120~520 pcs/min. | 80~520 pcs/min. | 80~520 pcs/min. |

| Working diameter of wire | #6(Ø2.8)~#14(Ø5.45), NO.1~NO.3 | #6(Ø2.8)~#14(Ø5.45), NO.1~NO.5 | #6(Ø2.8)~#14(Ø5.45), NO.1~NO.5 |

| Working length | 9.5~127 mm (3/8”~5”) | 9.5~127 mm (3/8”~5”) | 16~203 mm (3/4”~8”) |

| Specification Tool | MA,MB | MB,MC | MB,MC |

| The size of the equipment in the package | 1990х1610х1790 mm | 2420х1820х1910 mm | 2420х1820х1910 mm |

| The net weight of the equipment | 1944 kg | 2206 kg (2S +2 kg) | 2354 kg (2S +2 kg) |

| Weight | 2250 kg | 2556 kg (2S +2 kg) | 2704 kg (2S +2 kg) |

Self-tapping screw with a drill

ACCESSORY FOR EQUIPMENT

Stand for material supply to the machine