COILING AND FORMING MACHINES FOR SPRINGS, RINGS AND SPECIAL FASTENERS

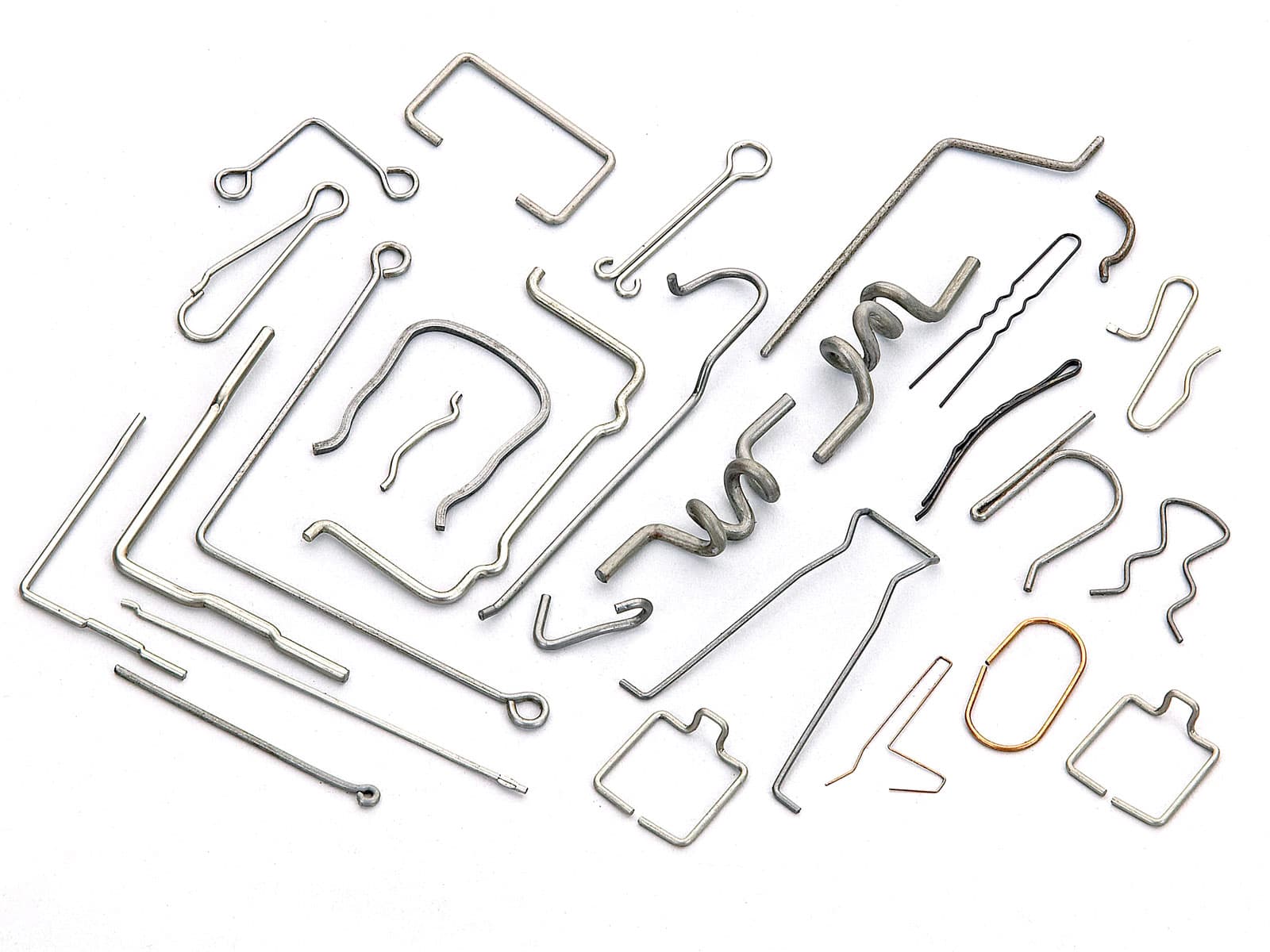

Multi-slide presses are specialized equipment designed for forming products from wire, metal strips, and strips through stamping. They find applications in the mass production of various items, including components for contact groups, terminals, clamps, and other electrical engineering elements; fasteners, buckles, connections, and clips in the automotive industry and other sectors of mechanical engineering; as well as specialized types of spring elements, brackets, hooks, and more used in construction.

The utilization of multi-slide presses is particularly justified in large-scale production scenarios, where there is a need to manufacture significant quantities of similar products. This is attributed to the requirement for distinct toolsets for each product type.

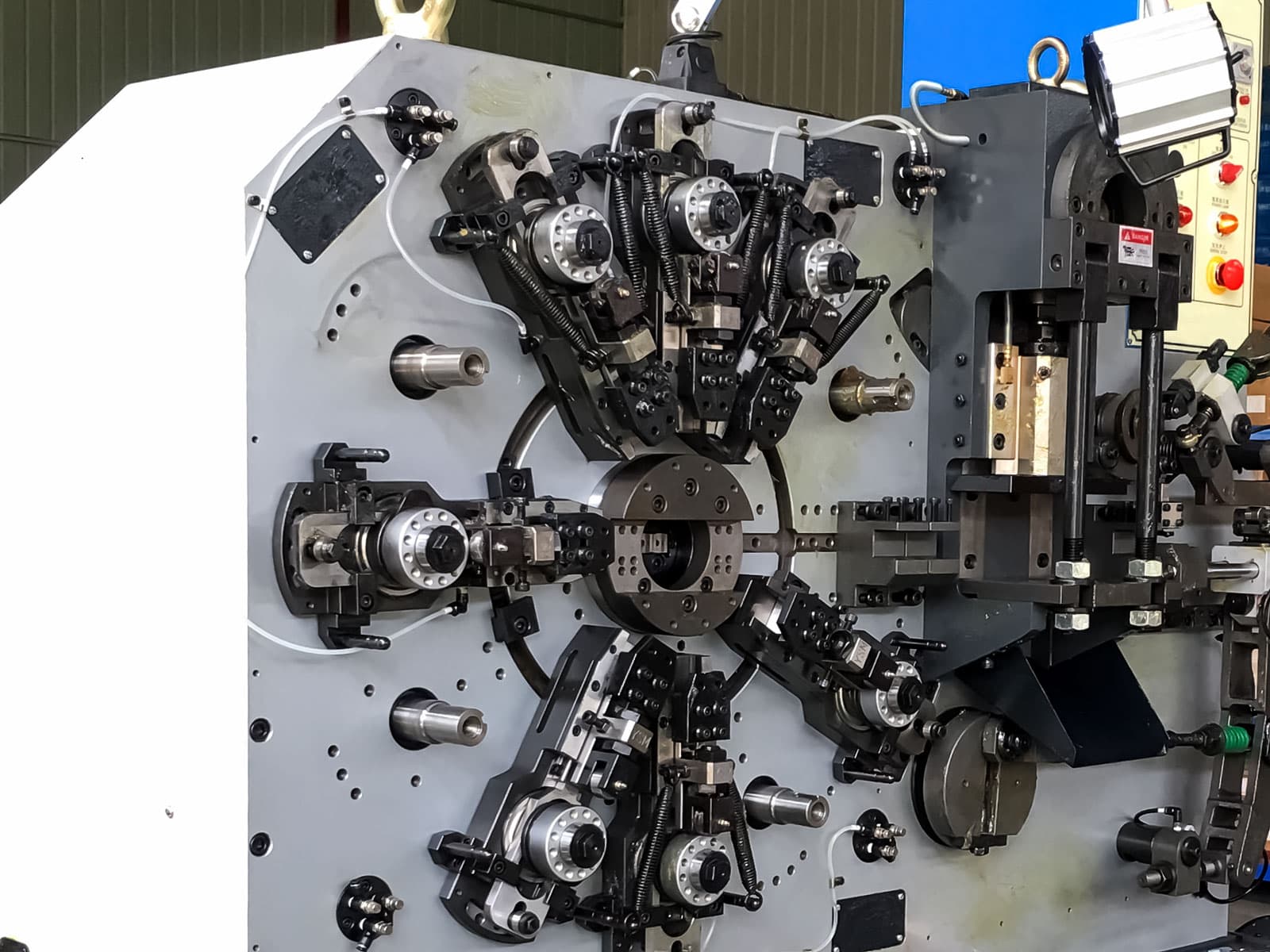

The operational principle of these forming machines is centered around impacting the workpiece with specially shaped tools. These tools move radially within eight or more sliders positioned on the vertical front panel of the molding machine, controlled by a cam mechanism or servos. Additionally, certain models of multi-slide machines are equipped with a punching press, which is installed along the material path towards the central forming mechanism. Utilizing specially designed dies, this press performs operations such as slotting and bending.

Machines for forming tape or wire come equipped with an automatic unwinder and a straightening and cutting device at the machine's entrance. Some molding machine models can be integrated with supplementary devices, such as thread rolling or thread cutting tools, as well as special attachments for exerting lateral forces (3D molding). Multi-slide presses are supplied with one or more toolkits tailored to specific product requirements.

Automatic Clamps Forming Machine RGT-26

Automatic machine for forming wire with a diameter of 0.6 - 2.5 mm and strips up to 30 mm wide and 0.3-1.2 mm thick. This multiforming machine is used for the production of clamps of various sizes and shapes, fasteners, hardware, door trims and hinges, brackets, springs, paper clips, clips, stationery, pins and barrettes, hangers, hooks, carabiners, terminals, contact groups and other electrical installation products.

Clamps Forming Machine Specifications

| Wire Diameter | Ø0.6 - Ø2.5 mm |

|---|---|

| Maximum width of strip | 30 mm |

| Thickness of strip | 0.3 - 1.2 mm |

| Maximun hardness of strip | 80 HRC |

| Maximum length of feeding | 200 mm |

| Maximum forming speed | 620 pcs/min |

| Press capacity | 10 tons |

| Slide capacity | 1.5 tons |

| Press stroke | 12 mm |

| Slide stroke | 37 mm |

| Motor Power | 5 HP (3.7 kW) |

| Machine Size, L × W × H | 2000 × 990 × 1900 mm |

| Equipment weight | 2100 kg |

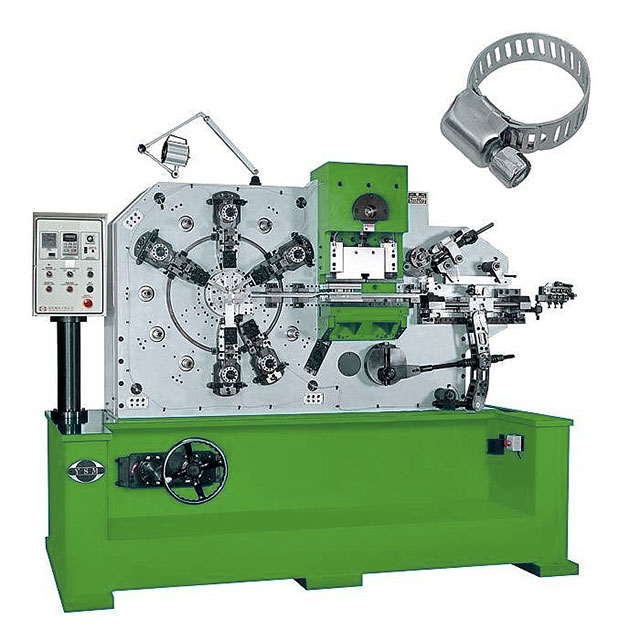

Automatic machine for the production of staples, rings, clamps, cotter pins STR-38

Equipment purpose

The automatic profile bending machine STR-38 for the production of staples, rings, clamps, cotter pins, wire bending and strips is designed for forming wire with a diameter of 1.5-5.0 mm and strips up to 50 mm wide and 0.8-2.0 mm thick.

Productivity - up to 150 products per minute. The machine is equipped with a wire unwinder with a load capacity of 200 kg. There are a number of standard and additional options.

Profile Forming Machine Description

- The automatic machine for forming wire and strip is used for the production of fasteners, staples, rings, clamps, cotter pins DIN 94, DIN 11024, contact groups and other electrical installation products.

- Control type - control panel with joysticks, CNC system.

- The main movement drive type is electromechanical.

- Installation - floor.

Automatic Roll Forming Machine Specifications

| Wire Diameter | 1.5 - 5.0 mm |

|---|---|

| Maximum width of strip | 50 mm |

| Thickness of strip | 0.8 - 2.0 mm |

| Maximun hardness of strip | 80 HRC |

| Maximum length of feeding | 320 mm |

| Maximum forming speed | 150 pcs/min |

| Press capacity | 30 tons |

| Slide capacity | 6.5 tons |

| Press stroke | 16 mm |

| Slide stroke | 42 mm |

| Power | 7.7 kW |

| Machine Size, L × W × H | 3330 × 1600 × 2400 mm |

| Equipment weight | 6500 kg |

Video of the operation of automatic equipment for stamping clips from strips

Automatic machine for the manufacture of steel clamps

SPLINT AND CLAMP FORMING MACHINE

SPECIFICATIONS

| Model | RG-138F | RG-270F | RG-270SF |

|---|---|---|---|

| Wire diameter | steel: Ø1.0-Ø2.0 mm из железа: Ø1.0-3.8 mm | steel: Ø2.0-Ø4.0 mm из железа: Ø3.0-6.0 mm | steel: Ø4.0-Ø9.0 mm из железа: Ø5.0-12.0 mm |

| Wire length | 125 mm | 245 mm | max. 450 mm |

| Performance | 60 Hz: 67,103,162,260 50 Hz: 53,81,128,205 | 11-65 pcs / min (device for switching DISCO speed) | 2-48 pcs / min (device for switching DISCO speed) |

| Basic engine | 1 hp | 3 hp | 5 hp 3 kW |

| Dimensions of equipment | 128х63х158 cm | 162х114х190 cm | 227 х 145 х 220 cm |

| Dimensions of equipment in packaging | 172х75х182 cm | 175х127х220 cm | 227 х 145 х 223 cm |

| Equipment weight | 800 kg | 1920 kg | 2700 kg |

| Weight of Equipment in packaging | 920 kg | 2300 kg | 3200 kg |

Note:

| |||

FORMING MACHINE FOR COTTER PINS, CLAMPS, SPECIAL PARTS, COMPRESSION SPRINGS

Cotter pin making machine is one kind of wire forming machine,material of cotter pin is steel semi circle wires which produce on semi circle wire machine,you can change cotter pin making machine die to make different size of cotter pins.

SPECIFICATIONS

| Model | RG-323-CNC(SF) | RG-138-CNC-F | RG-270-CNC-F | |

|---|---|---|---|---|

| Wire diameter | Ø0.4-Ø2.3 mm | steel: Ø1-Ø2 mm iron: Ø1-3.8 mm | steel: Ø2-Ø4 mm iron: Ø3-6 mm | |

| Performance | - | 60-200 pcs/min. | 10-90 pcs/min. | |

| Wire feed speed | 0-90 m/min. | - | - | |

| Wire length | - | 125 mm | 245 mm | |

| Max. outer diameter of the spring | 40 mm | - | - | |

| Servomotor | Wire feed | 2 kW | 2 kW | 3 kW |

| Chamber | 3 kW | 1 kW | 3 kW | |

| Rotary spindle | 0.75 kW | - | - | |

| Tension | 220V, 3 phase | - | - | |

| Dimensions of equipment | 180 х 72 х 180 cm | 184 х 70 х 155 cm | 162 х 114 х 190 cm | |

| Dimensions of equipment in packaging | 188 х 148 х 192 cm | 200 х 85 х 980 cm | 175 х 127 х 220 cm | |

| Equipment weight | 800 kg | 800 kg | 1920 kg | |

| Weight of Equipment in packaging | 1270 kg | 980 kg | 2300 kg | |

HEAVY DUTY TORSION SPRING FORMING MACHINE

SPECIFICATIONS

| Model | RG-18-CPS | RG-18-KRS |

|---|---|---|

| Wire diameter | Ø1.2-Ø1.6 mm | Ø1.2-Ø2.0 mm |

| The outer diameter of the spring (max.) | 10 mm | 20-30 mm |

| Number of turns of wire | 4-12 | 1-2 |

| Foot length | 22-30 mm | - |

| Winding direction | clockwise | clockwise |

| Performance | 20 pcs / min. | - |

| Engine power | 1 hp | 1 hp |

| Dimensions of equipment | 115 х 86 х 113 cm | 115 х 86 х 113 cm |

| Dimensions of equipment in packaging | 122 х 96 х 153 cm | 122 х 96 х 153 cm |

| Equipment weight | 440 kg | 440 kg |

| Weight of Equipment in packaging | 550 kg | 550 kg |