THREAD ROLLING MACHINES FOR THE FASTENERS INDUSTRY

THREAD ROLLING MACHINES FOR NUTS

INTEGRATED TAPPING EQUIPMENT

Features of tapping equipment

- Pneumatic cylindrical pusher allows you to adjust the stroke length.

- Speed thread rolling, parameters and productivity of the equipment controlled by a programmable interface and the inverter.

- The alarm system warns of failures, the absence of blanks, parts jams, overload, abnormal air pressure, etc .

- Device sorting defective product automatically removes defective products.

- Design of the tool unit can quickly replace hardware tools.

Number of product kinds

- Lock nuts: DIN 980, 982, 985, 6924, 6925, 6926, 6927

- Square weld nuts: DIN 928, 929

- Square nuts: DIN 557

- Square low nuts: DIN 562

- Hex low castle nuts: DIN 937, 979

- Hex low nuts: DIN 439, 936

- Hex Nuts: DIN 555, 934, 971, 2510, 6915

- Hexagon castle nuts: DIN 935

- Hexagon nuts with flange: DIN 6923

Specifications of nuts tapping equipment series RNT

| Equipment Model | 11(A/C) | 16(A/C) | 19(A/C) | 24(A/C) | 30(A/C) | |

|---|---|---|---|---|---|---|

| Hex Nuts | Metric sizes | M4-M10 | M8-M12 | M10-M14 | M12-M18 | M16-M24 |

| Dimensions in inches | 3/16"-1/4" | 5/16"-3/8" | 3/8"-1/2" | 1/2"-5/8" | 5/8"-7/8" | |

| Max. Performance pcs. / min. | 350-320 | 270-230 | 210-160 | 160-120 | 120-100 | |

| Nuts with flange | Metric sizes | M4-M10 | M8-M12 | M10-M14 | M12-M18 | M16-M24 |

| Dimensions in inches | 3/16"-1/4" | 5/16"-3/8" | 3/8"-1/2" | 1/2"-5/8" | 5/8"-7/8" | |

| Max. Performance pcs. / min. | 210-180 | 160-130 | 140-115 | 115-95 | 85-70 | |

| Number of main engines | 4 | 4 | 4 | 4 | 4 | |

| Max. flange diameter, mm | 16.5 | 23.5 | 26.5 | 35 | 45 | |

| Motor power, PM | 1.2 | 2.4 | 2.4 | 3.4 | 5.4 | |

| Spindle speed, vol./ Min. | 2096 | 1629 | 1425 | 1166 | 855 | |

| Net weight, tone | 1000 | 1500 | 1700 | 2100 | 3400 | |

| Oil tank capacity, L | 250 | 400 | 400 | 550 | 700 | |

| Equipment Dimensions (LxWxH), mm | 1060x1370x1930 | 1450x1600x1930 | 1450x1600x1930 | 1620x1870x1930 | 1700x2300x2140 | |

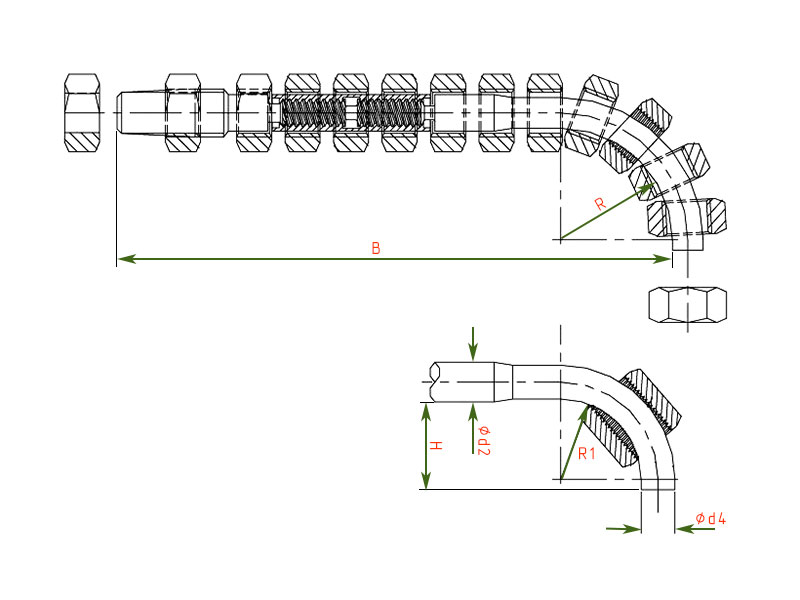

Working principle of RNT series nut tapping equipment

The stamped blank of the nut is fed to the intermediate hopper and then to the receiving hopper of the nut-cutting machine. From the hopper, the workpiece falls along vertical guides into the thread cutting unit, where the pneumatic pusher presses the nut workpiece against the driven rotating tap, pushing it along the working part of the tap rod, forming an internal thread. Finished nuts are dumped from the tail end of the curved tap into the finished product container.

Additional features. Equipment for rolling threads on nuts. Standard series RNF

| Standard (type C) | Advanced (Type A) | |

|---|---|---|

| Operator Interface | О | |

| Magnetic chip separator | R | O |

| Wear-resistant threading spindle | R | O |

| Oil protection cover | X | O |

| Wear-resistant hopper | R | O |

| Main motor inverter | R | О |

| Air tank | X | O |

| Automatic rejection device for defective products | X | O |

Video of the operation of the nut cutting equipment

PNEUMATIC FOUR-SPINDLE THREAD-ROLLING MACHINE FOR NUTS

Equipment for thread cutting /rolling for standard, flange, round nuts. This nuts tapping machine is designed for cutting hexagon, four-sided, nylon and flange nuts. Thread-rolling machine pitch fully complies with the requirements for the processing of nuts in different shapes, lengths and hardness. Convenient location of the control panel, easy operation. Each axis can be operated independently. Using the control panel, you can freely choose the left or right cutter, adjust the length of cut, adjust the speed of rotation of the tool axis. The process of cutting is controlled by a programmable logic controller (PLC).

The machine has the following components: an independent counter, independent control of the automatic thread cutter with circulation, management of supply, monitoring and control system, alarm system. Checking the current sensor to automatically control the process of cutting and the nut jam when applying that helps avoid breaking the mold. Tool exchange is simple and fast. A system of filtering the iron residues. The machine got CE certificate and fully complies with the EU's health and safety standards.

Number of product kinds

Hex low castle nuts: DIN 937, 979

Hex low nuts: DIN 439, 936

Hex Nuts: DIN 555, 934, 971, 2510, 6915

Hexagon castle nuts: DIN 935

Hexagon nuts with flange: DIN 6923

Square weld nuts: DIN 928, 929

Square nuts: DIN 557

Square low nuts: DIN 562

Lock nuts: DIN 980, 982, 985, 6924, 6925, 6926, 6927

Features of thread rolling equipment for nuts

- The machine cuts the thread on hexagon, square, nylon nuts, nuts with flange.

- The control panel has simple and accessible interface, allowing you to configure the thread (for example, cutting to the right or left direction).

- Each spindle operates independently, individually.

- The programmable controller is used for workflow management, selection of manual / automatic control, adjust the speed, the reporting of faults in the case of a missing or jammed blank.

- Tools exchange is easy and saves time.

- Magnetic filter maintains the working oil in the pure state.

Specifications of nuts tapping equipment

| Model | RHT-11 | RHT -14 | RHT -19 | RHT -24 | RHT -32 | RHT -38 | RHT -45 |

|---|---|---|---|---|---|---|---|

| Diameter of the cutting thread | M4~M6 3/16"~1/4" | M6~M8 1/4"~5/16" | M10~M12 3/8"~1/2" | M14~M16 1/2”~5/8” | M18~M22 3/4”~7/8” | M22~M24 7/8”~1” | M24~M30 1”~1¼” |

| Max. outer diameter, mm | 14 | 19 | 26 | 35 | 46 | 50 | 55 |

| Max. Performance, pcs. / min. | 470 | 360 | 240 | 140 | 100 | 60 | 50 |

| The power consumed from the network, kW | 0.75 | 1.5 | 2.2 | 2.2 | 3.7 | 5.5 | 2.2 (1:5S) |

| Max. energy consumption, kW/h. | 3.7 | 7 | 10 | 11.1 | 17.4 | 25.4 | 12.2 |

| Air consumption, L/min. | 208 | 346 | 233 | 339 | 412 | 624 | 542 |

| Oil tank, L | 230 | 300 | 380 | 480 | 600 | 650 | 750 |

| Machine dimensions, WxDxH, m | 1.4x1.2x1.8 (B) 1.9x1.2x1.8 (C) | 1.5x1.3x1.8 (B) 2x1.4x1.8 (C) | 1.7x1.4x2.1 (B) 2.1x1.5x2.1 (C) | 1.9x1.7x2.3 (B) 2.2x2.3x2.3 (C) | 2x1.9x2.4 (B) 2.8x2.5x2.4 (C) | 2.5x2.1x2.6 (B) 3x2.7x2.6 (C) | 2.5x2.2x2.7 (B) 3.2x2.7x2.7 (C) |

| Net Weight, kg. | 970 (B) 1100 (C) | 1200 (B) 1400 (C) | 1450 (B) 1650 (C) | 2400 (B) 3000 (C) | 3300 (B) 3600 (C) | 4500 (B) 5100 (C) | 5200 (B) 5800 (C) |

Standard and optional equipment of the tapping machine

| Set of equipment | 4-spindle tapping machine | ||

|---|---|---|---|

| RHT-B | RHT-C | ||

| 01 | Sensor device for Safety of unloading unit | О | О |

| 02 | Thermally stable protective shields of unloading gate | О | О |

| 03 | Regulatory mechanism to control the pusher timeout | О | О |

| 04 | Mechanism for setting feeding time | О | О |

| 05 | Sensor for lack of blanks | О | — |

| 06 | Loading chute | R | — |

| 07 | Mechanism of automatic blank feeding (hopper / conveyor) | R | R |

| 08 | Mechanism for chip removal | R | R |

| 09 | Inverter | R | R |

| 10 | The interface (panel) of operator | — | О |

| 11 | Oil protective casing | — | О |

| 12 | Certification of Safety Equipment (СЕ) | — | О |

SINGLE-SPINDLE NUT THREADING MACHINE SERIES JTR

Features of the nut threading machines of the series JTR

- Pitch-lead tapping design gives precise and accurate thread form.

- The tapping depth is fixed and that is best for blind hole nuts.

- Safety devices, Torque control, feed lead, and self-radial-adjustment, clamping chuck, prevent taps from damage and increase the operation safe.

- Easy to install tooling. It is easy to replace parts for different nuts tapping.

- Governed by PLC program.

- Screen shows the production status.

- Double tap protection. The machine will stop automatically when it detects abnormal nuts or other safety issue.

Threading Equipment Specifications

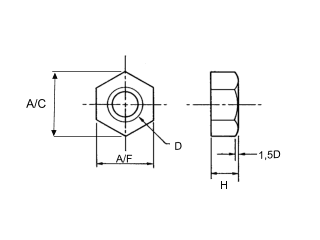

| Model | JTR12 | JTR20 | JTR30 |

|---|---|---|---|

| Tap size: | M2-M12 | M12-M20 | M12-M30 |

| Nut AF: | 10-28 mm | 10-28 mm | 15-50 mm |

| Capacity: | 16-60 pcs/min | 4-20 pcs/min | 4-16 pcs/min |

| Spindle Travel: | 65 mm | 80 mm | 80 mm |

| Nut Lenght: | 6-60 mm | 6-75 mm | 10-90 mm |

| Servo Motor: | 1500 W | 3000 W | 3000 W |

| Hydraulic Motor: | 1 HP | ||

| Coolant Motor: | ¼ HP | ¼ HP | ½ HP |

| Coolant Tank: | 35 L | 35 L | 40 L |

| Weight: | 800 kg | 1025 kg | 1550 kg |

| Dimension: | 1250 × 1200 × 1850 mm | 1250 × 1200 × 1950 mm | 1460 × 1675 × 2000 mm |

Standard equipment package

| HMI servo motor | 1 |

|---|---|

| Vibration hopper | 1 |

| Tool kit | 1 |

Thread cutting process on JTR series thread-rolling machine

PNEUMATIC TWO-SPINDLE THREAD-ROLLING MACHINE FOR NUTS

HLT thread-rolling machine for nuts saved all features of the model of HNT series, but this machine supports a wide range of threads. This product has a fairly wide range of applications and meets the requirements of a variety of small-scale industries. It is equipped with a cruise control function, which ensures easy operation and maximum performance. HLT machine is designed for cutting hexagon, four-sided nylon nuts and flange nuts. This machine fully complies with the requirements for the processing of the nuts of various shapes, sizes and hardness.

Features of thread rolling equipment for nuts

- Tapping machine cuts the threads on the nut of different sizes, including special forms of fasteners.

- Suitable for small batch production.

- Inventors allows you to adjust the speed and correspondingly change the performance of the hardware.

- Tapping machine is able to put a thread on hexagon, square, nylon nuts and bolts with flange.

Number of product kinds

Hex Nuts: DIN 555, 934, 971, 2510, 6915

Anchor nuts for special purposes: DIN 798

Caste nuts: DIN 935

Hex low nuts: DIN 936

Hex low castle nuts: DIN 937, 979

Lock nuts: DIN 980, 985, 6924, 6925

Lock check nuts: DIN 7967

Specifications of nuts tapping equipment

| Model | RLT-13 | RLT-22 | RLT-33 | RLT-45 | RLT-70 | RLT-90 |

|---|---|---|---|---|---|---|

| Diameter of the cutting thread | M5~M10 3/16"~3/8" | M10~M16 3/8"~5/8" | M16~M24 5/8"~7/8" | M24~M30 1”~1¼” | M30~M48 1 1/8”~1 3/4” | M48~M60 2 1/8”~2 1/2” |

| Max. outer diameter, mm | 23 | 35 | 46 | 55 | 86 | 105 |

| Max. Performance pcs. / min. | 180 | 100 | 50 | 20 | 10 | 4 |

| The power consumed from the network, kW | 1.5 | 2.2 | 5.5 | 2.2 (1:5S) | 3.7 (1:5S) | 5.5 (1:5S) |

| Max. energy consumption, kW/h. | 3.7 | 6.3 | 9.3 | 7.1 | 10.8 | 14.4 |

| Air consumption, L/min. | 128 | 242 | 206 | 216 | 145 | 81 |

| Oil tank, L | 170 | 300 | 400 | 550 | 650 | 800 |

| Machine dimensions, WxDxH, m | 1.6x1.4x1.7 | 2x2.4x1.9 | 2.1x2.6x2.1 | 2.3x2.8x2.3 | 2.1x2.2 x2.5 | 2.7x3.1x2.7 |

| Net Weight, kg. | 1280 | 1950 | 2800 | 3750 | 4700 | 5400 |

TWO-SPINDLE ALTERNATING THREAD-ROLLING MACHINE FOR NUTS

It is the tapping equipment of higher class, in which, instead of conventional engines with the traditional approach to managing, there are servomotors and human-machine interface. This design offers more functionality has more advantages in the management and operation. The machine is used not only for drilling and cutting acorn nuts, but also for cutting shaped nuts. Reinforced structure will provide a longer life than the traditional vertical threading machine. As a result of the application of the guiding thread the machine with high speed can ensure the accuracy of the depth of cut, and does not destroy the structure of the flat nut. HRT machine carries out control of deviations for high quality thread cutting tool and conduct a comparative test. The machine has been tested for suitability standards of CE, its design meets safety requirements.

Features of thread rolling equipment for nuts

- Multifunctional: threads on flat, hex nuts and bolts of non-standard sizes.

- The equipment is equipped with a servomotor and the man-machine interface.

- Supports tread-rolling at high speeds.

- Thread rolling equipment has been certified.

Hexagon flat nuts: DIN 986, DIN 1587

Hex Nuts: DIN 917

Specifications of nuts tapping equipment

| Model | RRT-13 | RRT-22 | RRT-33 |

|---|---|---|---|

| Diameter of the cutting thread | M3~M8 1/8"~5/16" | M8~M14 5/16"~9/16" | M14~M22 9/16"~7/8" |

| Maximum pitch, mm | 45 | 60 | 100 |

| Max. outer diameter, mm | Ø18 | Ø24 | Ø36 |

| Max. Performance, pcs. / min. | 70 (C) 90 (D) | 50 (C) 70 (D) | 30 (C) 50 (D) |

| The power consumed from the network, kW | 0.75 (C) 1.5 (D) | 1.5 (C) 3 (D) | 3.7 (C) 5.5 (D) |

| Max. energy consumption, kW/h. | 4.3 (C) 5.8 (D) | 7.5 (C) 10.5 (D) | 11.9 (C) 15.5 (D) |

| Oil tank, L | 120 | 150 | 180 |

| Dimensions of the machine , WxDxH, m | 1.85x1.5x1.93 | 2.25x1.9x2.15 | 3x2.15x2.43 |

| Net Weight, kg. | 1410 | 1980 | 2760 |

UNIVERSAL TWO-SPINDLE THREAD-ROLLING MACHINE FOR NUTS

Tapping machine of RDT series has a fairly wide range of applications and meets the requirements of various industries. Rotational speed of the machine is changed by a frequency converter. The result is that the machine is easily controlled and reaches maximum performance. Machine is suitable for the production of various shaped nuts. In this machine the material is fed into the threaded installation vibrating screen, which sorts the nuts. This machine is a high-performance threading equipment and can be a good alternative to the universal reciprocating threading machines for processing shaped nuts.

Features of thread rolling equipment for nuts

- The machine cuts the thread on nuts of different sizes, including special form fastener.

- Inventors allows you to adjust the speed and correspondingly change the performance of the hardware.

- The equipment cuts the threads on nuts for special purpose.

- Fasteners feeding is performed by vibrating device.

Knurled and collar nuts with flange: DIN 466

Wing nuts: DIN 315

Screwed Plugs: DIN 7965

Wheel nuts: DIN 74361

Specifications of nuts tapping equipment

| Model | RDT-13 | RDT-22 | RDT-33 | RDT-45 |

|---|---|---|---|---|

| Diameter of the cutting thread | M5~M8 3/16"~5/16" | M10~M14 3/8"~9/16" | M16~M22 5/8"~7/8" | M24~M30 1”~1¼” |

| Max. outer diameter, mm | 19 | 35 | 46 | 55 |

| Max. Performance, pcs. / min. | 200 | 110 | 60 | 20 |

| The power consumed from the network, kW | 1.5 | 2.2 | 3.7 | 2.2 (1:5S) |

| Max. energy consumption, kW/h. | 5.8 | 7.4 | 10.8 | 7.8 |

| Air consumption, L/min. | 170 | 332 | 231 | 282 |

| Oil tank, L | 170 | 280 | 350 | 500 |

| Machine dimensions, WxDxH, m | 1.25x1.3x1.8 | 1.55x1.45x2 | 1.65x1.6x2.1 | 1.8x2x2.3 |

| Net Weight, kg. | 1080 | 1700 | 1900 | 2500 |

Machine Tools and Supplies for nut cutting machines

Taiwan Metiz Alliance supplies a wide range of machine tools and spare parts for nut tapping machines, nut taps, machine parts, wear parts and spare parts for various types of equipment.