SYNTHETIC OILS FOR INDUSTRIAL MECHANISMS

OILS FOR STAMPING, PERFORATING, BENDING AND HARD OPERATING CONDITIONS

Synthetic oils of highest quality, designed for closed type industrial mechanisms, operating at high pressure and at a wide range of extreme temperatures, formulated using advanced synthetic base oils and process additives, has excellent anti-wear properties, guarantee low temperature fluidity and outstanding oxidizing and thermal stability for extending the life cycle of working fluids and components. Oils increase the efficiency of transmissions over a wide range of temperatures, and can reduce power consumption.

We offer a wide range of oils for industrial equipment and for consumer applications, hardware, automotive industry and metalworking. Products are safe to use and do not pollute the environment.

Oil for the equipment with drying and force separation system, cleaning is not required. Oil removing from parts surface is carried out by quick heat degreasing.

Oil for the equipment, cleaning is not required, chloride-free with drying system and oil separation.

Chloride-free oil for the equipment is not dangerous for the environment and provides corrosion protection.

Oil for the equipment operating without any cleaning agents and solutions. The equipment excludes the necessity of using cleaning agents and solutions.

Oil for the equipment with drying and force separation system, cleaning is not required AQ-PRESS RB-1 SERIES

Oil removing from parts surface is carried out by quick heat degreasing.

| V-1 | RSL | RL | RS | RSH | Reasons for the lack of necessity in degreasing: | |

| Drying | on a high speed | fast | standard | slow | AQ-PRESS RB-1 SERIES High quality reclaimed. | |

| Density | 0.781 | 0.80 | 0.84 | 0.85 | ||

| Viscosity | 1.5 | 2.8 | 8.6 | 11.7 | AQ-PRESS RB-1 SERIES Without harmful impurities, chlorum and sulfur, not dangerous for the environment. |

Oil for the equipment, cleaning is not required AQ-PRESS SERIES

Oil for the equipment, chloride-free with drying system and oil separation.

| Item | Density, 15°C | Viscosity, 40°C | Flash point, °C | Residual oil,% | Carrying capacity, kg/cm2 | Drying time | |

| Product name | |||||||

| Full flashing "0" Type | RGS-1 | 0.75 | 1.20 | 41 | 0 | 1.0 | 15 min < |

| RGS-5A | 0.75 | 1.35 | 46 | 0 | 1.0 | 20 min < | |

| RGS-7 | 0.78 | 1.70 | 63 | 0 | 2.0 | 3 h > | |

| Equipment with advanced operational characteristics | |||||||

| RFIX-3 | 0.76 | 1.38 | 49 | 0 | 3.0 | 1 h > | |

| RFIX-4 | 0.77 | 1.60 | 63 | 0 | 3.5 | 3 h > | |

| RFIX-5 | 0.78 | 2.20 | 86 | 0 | 4.0 | 24 h < | |

| RMB-10R | 0.77 | 1.45 | 49 | 0 | 11.5 | 1 h < | |

| RMB-10L | 0.79 | 1.85 | 63 | 0 | 11.5 | 3 h > | |

| RMB-10I | 0.81 | 2.55 | 86 | 0 | 12.0 | 24 h < | |

| RMB-13NR | 0.77 | 1.60 | 50 | 0 | 12.5 | 1.5 h > | |

| RMA-13SPR | 0.84 | 2.10 | 49 | 0 | 11.5 | 6 h < | |

| RMA-18SPR | 0.88 | 2.85 | 56 | 0 | 12.5 | 6 h > | |

| RST-25 | 0.92 | 4.0 | 71 | 0 | 8.5 | 3 h > | |

| Partial remainder | RC-3 | 0.77 | 1.60 | 48 | 0.5 | 1.5 | 5 h > |

| RAC-5F | 0.76 | 1.37 | 49 | 1.0 | 2.0 | 1 h > | |

| RAR-5S | 0.76 | 1.40 | 49 | 2.5 | 3.0 | 1 h > | |

| RC-20SP | 0.79 | 1.95 | 48 | 3.0 | 7.0 | 5 h > | |

| RSR-1D | 0.76 | 1.42 | 49 | 3.5 | 3.5 | 1 h > | |

| RLG-11S | 0.76 | 1.40 | 49 | 4.0 | 2.5 | 1 h > | |

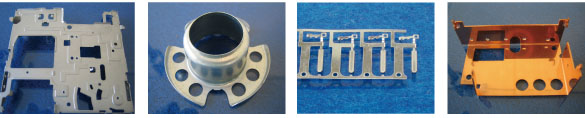

Examples of synthetic oils not requiring to clean items

| Stamping items | Oil type | Material/ thickness | Process | |

| Car parts | Seals and fillers | RGS-5A Full flashing | stainless steel 0.3 mm | perforation, bending |

| Fuel elements | RGS-1 Full flashing | nickel 0.12 mm | rings heading | |

| Regenerators | RFIX-4 Full flashing | cooper, aluminium tubes diameter 6-30 mm thickness 0.3-1.4 mm | bending, towing | |

| Connectors | RSR-1D Partial remainder | brass 0.8 mm | perforation, bending | |

| Air cushion parts | RFIX-15P Full flashing | galvanic coating 1.0 mm | perforation, bending | |

| Electronic components and parts for domestic use | Air conditioners | RGS-1 Full flashing | colored sheet steel 0.8 mm | perforation, bending, drawing |

| Washing machines drums | RST-25 Full flashing | stainless steel 0.5-0.6 mm | perforation, deflashing, coiling | |

| Plasma and LCD televisions parts | RMB-10R, RMB-10L, RFIX-4 Full flashing | sheet steel with treated surface, aluminium | perforation, bending, drawing, thread cutting | |

| Water heaters | RFIX-4, RFIX-5 Full flashing | cooper tubes | bending, rolling | |

| Batteries parts | RGS-5A Full flashing | stainless steel, nickel, aluminium 0.1-0.5 mm | perforation, milling, soldering, calking | |

| Cooling chambers parts | RGS-5A Full flashing | galvanic coating 0.6-1.0 mm | perforation, bending, drawing | |

| Air conditioners’ aluminium parts | RAL-1H Full flashing | aluminium material <0.2 mm | deflashing | |

| Construction elements | Safety fencing | RGS-5A, RFIX-4 Partial remainder | colored sheet steel, galvanic coating 0.6-1.2 mm | rolling |

| Stamping items with drawing | RAR-5S Full flashing | aluminium 5.0 mm | milling,cutting (rotary saw) | |

| Cast parts | RMA-13SPR Full flashing | galvanic coating 0.6-1.2 mm | perforation, bending, drawing | |

| Perforating metal | RFIX-10, FIX-4 Full flashing | aluminium 0.6-1.0 mm | perforation | |

| Other | Metal cans | RFIX-4 full flashing RC-3 Partial remainder | material without tin-content 0.4 mm | perforation, bending |

| Mobile phones parts | RGS-5A, RFIX-4 Full flashing | silver and nickel material 0.15 mm | perforation, bending | |

| Vending machines parts | RMA-18SPR Full flashing | galvanic coating 1.2-1.6 mm | perforation, bending, drawing | |

| Water heaters | RMB-13NR Full flashing | aluminized material (powder aluminium) 0.8 mm | drawing | |

| Copying equipment parts | RGS-5A, RFIX-4 Full flashing | galvanic coating 0.6-1.2 mm | perforation, bending | |

| Aluminium castings | RMB-10I Full flashing | die casting | thread cutting | |

| Digital cameras parts | RST-25 Full flashing | stainless steel 0.5 mm | perforation, bending | |

| Engine parts | RLG-11S Partial remainder | silicon sheet steel 0.35-0.5 mm | perforation |

Chloride-free oil for the equipment AQ-PRESS RCF SERIES

Oil characteristics:

- Extended service life of metal molds.

- Excellent protection against jamming and seizing of metal products.

- As effective as equipment using chlorum content.

- No aggressive odors.

- Good detergency.

| Material | Product name | Viscosity, сСт | Flash point, °C | Carrying capacity, four balls hardness test | Peculiarities, application |

| Treatment of sound materials, stainless steel, carbon steel etc. (exl. Cooper) | RCF-100 | 97 | 180 | 14< | Fine blanking, shaving, deep drawing |

| RCF-170 | 167.7 | 200 | 14< | ||

| RCF-200 | 203 | 200 | 14< | ||

| RCF-295 | 286 | 200 | 14< |

Chloride-free oil for the equipment AQ-PRESS RF, RAL, RK SERIES

Chloride-free oil for the equipment is not dangerous for the environment and provides corrosion protection.

| Material | Product name | Viscosity, сСт | Flash point, °C | Carrying capacity, four balls hardness test | Peculiarities, application |

| Iron | RF-20A | 20.1 | 180 | 6< | perforation, bending, drawing of steel from 2 mm and less |

| RF-53A | 53 | 180 | 5< | ||

| Iron, stainless steel | RF-90A | 94.8 | 180 | 10< | perforation, drawing of steel from 3 mm and more, stainless steel from 2 mm and less |

| RF-215A | 212 | 180 | 10< | ||

| Aluminium | RAL-15G | 14.3 | 180 | 7< | perforation, bending, drawing |

| RAL-108G | 108.4 | 180 | 8.5< | ||

| Cooper | RK-40D | 40 | 180 | 7< | perforation, bending, drawing |

| RK-110D | 110 | 180 | 8< |

| Product name | Viscosity, 40°C | Flash point, °C | Chlorine content | Application | |

| Aluminium | RAL-1H | 1.70 | 49 | no chlorum | Air conditioning, in mechanisms containing aluminium particles, clearing is not required |

| RAL-2H | 2.30 | 86 | no chlorum | Air conditioning, in mechanisms containing aluminium particles, clearing is not required | |

| RAL-10SP | 6.60 | 130 | no chlorum | perforation, bending, shallow drawing | |

| RAL-34F | 47 | 180 | no chlorum | drawing | |

| RAL-57F | 67 | 180 | no chlorum | drawing | |

| RAL-150F | 159.4 | 180 | no chlorum | Secondary drawing of accumulator batteries bodies (cylinder, square) | |

| Cooper | RZ-8 | 1.45 | 49 | no chlorum | Protects parts from decolorization |

| RK-8D (new product) | 4.6 | 86 | no chlorum | Lead frames, connections | |

| RK-65D (new product) | 68.7 | 180 | no chlorum | drawing | |

| RK-16 | 16.2 | 160 | no chlorum | perforation, bending, VеLикоLепно Protects parts from decolorization | |

| RK-17 | 9.5 | 170 | no chlorum | perforation, bending, VеLикоLепно Protects parts from decolorization | |

| RK-30 | 6.5 | 71 | no chlorum | Connections, swaging parts etc. | |

| Stainless steel | RCX-7 | 3.24 | 50 | no chlorum | perforation, bending of steel from 0.5 mm and less |

| RCX-10 | 8.67 | 86 | no chlorum | perforation of small diameter steel from 1 mm and less | |

| RD-26F | 2.91 | 44 | no chlorum | Standard treatment of sheet steel | |

| RCF-200 | 197 | 250 | no chlorum | Sheet drawing with thinning, deep drawing | |

| Sheet steel with treated surface | RC-80F | 1.75 | 49 | no chlorum | Drying oil for drawing |

| RAR-80F | 13.7 | 50 | no chlorum | Universal oil, without the need of frequent change | |

| RF-50D | 50.3 | 160 | no chlorum | Standard neutral oil | |

| RF-185M | 136 | 180 | no chlorum | Drawing of non-standard parts | |

| Other (special purpose) | DRAW RSP-650 | 17.2 | 200 | no chlorum | Processing of metal products without bivalent iron content, stainless steel followed by heat treatment; Type - oil desolved in high temperature |

| DRAW RSP-3000 | 46.8 | 124 | no chlorum | ||

| DRAW RSP-3200 | 72.6 | 124 | no chlorum | ||

| RHP-1S | 5.7 | 49 | no chlorum | Nibs processing | |

| RHP-4 | 5.7 | 86 | no chlorum | Nibs processing | |

| RCF-100 | 97 | 180 | no chlorum | Fine blanking, shaving |

Oil for the equipment operating without any cleaning agents and solutions AQ-PRESS RSR-W SERIES

The equipment excludes the necessity of using cleaning agents and solutions.

| Degreasing by water rinsing | RSR-W series synthetic oils can be washed with water flushing under pressure. Flush water is recycled, the oil droplets have a sufficiently large size and easily removed from the aqueous environment. |

| Protection from corrosion of metal items | The water-soluble rust inhibitor does not leave spots on the surface of metal products, provides excellent protection against corrosion. |

| Wasteless recycling of used flush water | Used flush water is recycled and degreased without additional treatment facilities and solutions through the method of distillation and recovery by "CRS-20AQ" oil separator and "ES-100AQ" oil removal system developed by our company. Thus, we achieve waste-free processing of used flush water. |

Synthetic oils for iron, aluminium, cooper and brass parts RSR-W SERIES

| Product name | Viscosity, сСт | Carrying capacity, kg/cm2 | Peculiarities, application |

| RSR-8W | 2.56 | 13.5 | Back panels (colored sheet metal) for TV |

| RSR-18W | 2.95 | 14 | TV aluminium parts |

| RSR-24W | 7.2 | 10 | Deep drawing TV aluminium parts |

| RSR-116W | 16 | 8 | perforation, bending, deflashing, thread cutting |

| RSR-154W | 54 | 8.5 | perforation, bending, shallow drawing of items from 2 mm and less in thickness |

| RSR-165W | 65 | 10 | perforation, bending, drawing of items from 3 mm and less in thickness |

| RSR-177W | 77 | 11.5 | high-wearing feature, ideal for shaving etc. |

| RSR-188W | 88 | 13 | Ideal for deep drawing of items from 2 mm and less in thickness |

| RSR-198W | 98 | 16 | Ideal for deep drawing of items from 2 mm and less in thickness |

Synthetic oils for iron, stainless steel RSR-WS SERIES

| Product name | Viscosity, сСт | Carrying capacity, kg/cm2 | Peculiarities, application |

| RSR-114WS | 14 | 10 | perforation, bending of stainless steel from 1 mm and less |

| RSR-150WS | 51 | 11 | deflashing, perforation, bending of stainless steel from 1 mm and less |

| RSR-160WS | 59 | 12 | perforation, bending, shallow drawing of stainless steel items from 1 mm and less |

| RSR-170WS | 68 | 12 | drawing of stainless steel items from 1 mm and less |

| RSR-180WS | 79 | 14 | high-wearing feature, ideal for shaving etc. |

| RSR-190WS | 88 | 18 | Ideal for deep drawing of items from 2 mm and less in thickness, sheet drawing with thinning |

Spray washing test

Spray washing test under pressure shows us the fact that RSR-W Series synthetic oils can be well washed with water, without the use of additional agents.

The test condition:

- Variant A, washing by a spray can (using water only). Liquid temperature 60 °C pressure 0.2 MPa × 10 seconds.

- Variant B, washing by a spray can × 2 minutes (under the same conditions as the Variant A) > ultrasonic cleaning with a water temperature of 60 °C × 4 minutes.

Sample test: Variant A (blank 50 × 100 × 0.2 mm thickness) was immersed in SR-W Series oil. Then the test blank was heat treated in a furnace at 80 °C for 30 minutes. Then the test blank was subjected to testing the degree of degreasing.

| Product name | The test condition | Residual oil, mg/dm2 | |

| Flushing | ultrasonic cleaning | ||

| RSR-8W | variant A | 0.025 mg | 0.01 mg |

| RSR-24W | variant A | 0.05 mg | 0.01 mg |

| RSR-116W | variant В | 0.05 mg | 0.02 mg |

| RSR-165W | variant В | 0.075 mg | 0.02 mg |

| RSR-198W | variant В | 0.1 mg | 0.05 mg |

RSR-24W Series synthetic oil is used for deep drawing of aluminium parts for large LCD TVs. Finish parts cleaning is carried out by washing in water without adding detergents. Cleaning in hydrocarbon environment or with help of ultrasound is the most effective way of non-polluting.

Blank size: 750 × 1200 mm

The processing speed: 15 meters per minute (12 pcs. per minute).