EQUIPMENT FOR THE MANUFACTURING OF NAILS

NAIL MAKING TECHNOLOGICAL PROCESS

List of nail making equipment

Common smooth shank nails manufacturing

For a complete smooth shank nail production cycle, the following set of equipment is needed:

- Nail Making Machine

- Nail Polishing Machine for cleaning nails from oil, dirt, rust, and other residues

- Galvanizing equipment (if necessary, anti-corrosion coatings are applied to nails, usually galvanic zinc)

- Equipment for sharpening cutting knives of Nail Making Machine

Screw shank nails and ring shank nails manufacturing

Thread Rollers are used in the production of screw shank nails or ring shank nails. Smooth shank nails that are manufactured on a Nailing machine and cleaned on a Nail Polishing Machine are used as a blank for Thread Rolling Equipment. If necessary, screw shank nails and ring shank nails can be coated with an anti-corrosion coating (usually with galvanic zinc).

For a complete screw shank or ring shank nail production cycle, the following set of equipment is needed:

- Nail Making Machine

- Thread Roller

- Nail Polishing Machine

- Galvanizing equipment (if necessary, anti-corrosion coatings are applied to nails, usually galvanic zinc)

Wire Coil Nails Manufacturing

In the production of coil nails for pneumatic pistols, collator machines that solder nails on wire are used. Pierced, screw or special smooth nails are used as a blank for Collator Machines.

Collator equipment has a build-in varnishing and painting system.

For a complete coil nail production cycle, the following set of equipment is needed:

- Nail Making Machine

- Thread Roller

- Nail Polishing Machine

- Galvanizing equipment (if necessary, anti-corrosion coatings are applied to nails, usually galvanic zinc)

- Wire Coil Nail Collator for soldering nails to wire

Plastic strip nails manufacturing

For a complete plastic strip nail production cycle, the following set of equipment is needed:

- Nail Making Machine

- Thread Roller

- Nail Polishing Machine

- Galvanizing equipment (if necessary, anti-corrosion coatings are applied to nails, usually galvanic zinc)

- Plastic Strip Nail Collator

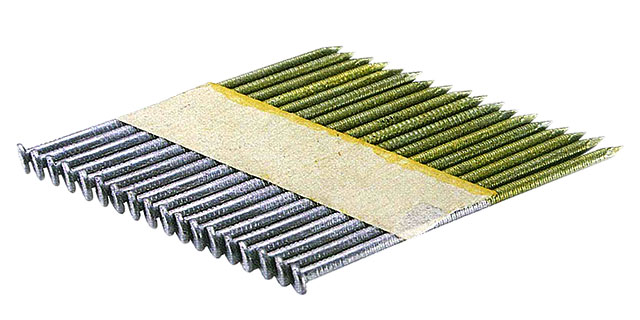

Paper strip nails manufacturing

For a complete paper strip nail production cycle, the following set of equipment is needed:

- Nail Making Machine

- Thread Roller

- Nail Polishing Machine

- Galvanizing equipment (if necessary, anti-corrosion coatings are applied to nails, usually galvanic zinc)

- Paper Strip Nail Collator

Nail making technological process flow chart

Wire Rod

Descaling

Wire-Drawing

Nail making

Polishing

finished products before control

and packaging operations

Finished Products Photos