SURFACE TREATMENT EQUIPMENT

SURFACE TREATMENT EQUIPMENT. ELECTROPLATING LINES

Equipment for galvanizing, phosphatizing and electroplating supplied by Taiwan Metiz Alliance combines high operational reliability, a high level of adaptability, widely used in factories leaders in the production of fasteners and components for the automotive industry, machine tools, microelectronics, fasteners and components for large construction companies.

Designing equipment for galvanizing are produced in AUTOCAD, followed by data conversion software with 3D-graphics, which in turn increases the accuracy of the design and makes it possible to develop customized products.

We offer equipment for galvanic surface treatment in a wide range of industries, ranging from industrial materials such as bolts, nuts, building material, finishing the car, motorcycle, sanitary ware, golf equipment, accessories for clothing, stationary items and even electronic components and computer parts, etc.

Detailed description of equipment

- E-CATALOG galvanic equipment presentation

- Specification of acid galvanizing and passivation line (white, yellow) in galvanic drums

- Galvanic line drawing

- Specification of acid galvanizing and passivation line (white, yellow) in galvanic drums and passivation (black, green) in baskets on U-form line

- U-form passivation line drawing

- Consumption rate of chemicals per galvanic of metalware line

- Electroplayting barrel

General view of the line for fasteners galvanizing

Completed projects. Galvanizing Line for bolts and nuts with galvanic drums. The equipment for wastewater and emissions treatment.

(click to enlarge images)

Why do so many partners from around the world choose our equipment?

FEATURES OF EQUIPMENT FOR GALVANICS COINFIGURATION

The first feature: Know-how in the design of galvanic drums, which was developed by our engineers, and was patented

Description of galvanic drums features

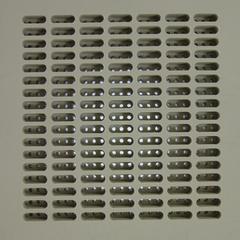

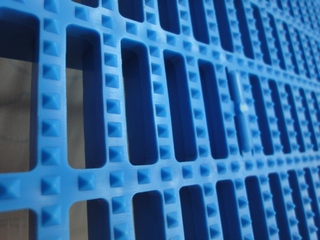

The galvanic drum is octagonal prism, one facet of which is the cap collected from full-sheet polypropylene and provided by bending the ends of gear wheels for driving the drum in rotation. Gears are fastened to the sections forming the side walls by means of ties of polypropylene. On one of the side walls there are removable covers for loading items into the drum. Drum sections are made with holes for passing the electrolyte and the current, and convex on the inner surface, preventing sticking of the flat parts.

Also, the drum has a cover with a locking knob. On the metal axis in the center of the drum, there are special conductive rings. These rings hurt workpieces during rotation of the drum. Thereby improving of the coverage quality is achieved in the processing of ultra-small fasteners. The drum can be used for machining the majority of technological processes with operating temperatures up to +80°C.

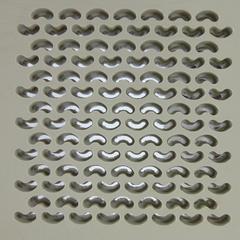

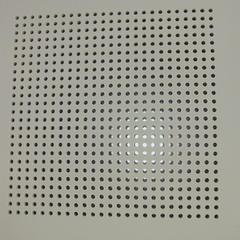

Form and Application of galvanic drum holes

Long holes are best suited for processing of bolts, screws, pieces of large size, large metal plates.

Arcuate holes are used for galvanic plating of flat parts, washers, rings, small metal plates.

Round holes are suitable for galvanizing screws, self-tappers, nails and fasteners of large sizes.

Round holes of larger diameter have good permeability indicator solution which in turn improves the quality of the plating.

The second feature: Know-how in the design of the holders of drums and electroplating baths

Holders of galvanic drums

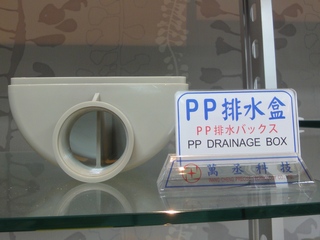

Through the use of lightweight alloy decreases the load on the engine, as well as the energy savings due to the lower weight.Use of the polypropylene coating over aluminum substantially increases corrosion resistance as compared to traditional methods of protection and at the same time serves for the electrical insulation of the line from other units.

The components of galvanic baths

Places of components contiguity of galvanic baths are carefully fixed by ties of polypropylene or by hot plastic soldering.

Design of galvanic drums surface

The third feature: The high electrical conductivity and small electrical loss of conductive elements

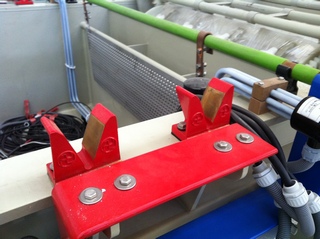

V-shaped copper foundation

The components of this unit are made with high precision on CNC machines have high electrical conductivity and low electrical losses.

The components of the device:

- Copper unit. Main function of a copper unit is supply of electricity to the axis and the rings of the drum.

- Black bushing of bakelite. It has electrical insulating properties and resistance to high temperatures.

- Fixed insulated steel plate.

- Bushing.

Galvanic drum holder

The main function of this unit is to support the drum stable. The item is made of aluminum alloy coated with method of injection of polyurethane foam manufactured in Germany. This V- shaped base is not a conductor and used directly to wash baths with hot and cold water, nitric acid and passivation baths.

Features of the holder:

- low weight and high strength at the same time thanks to the production of aluminum alloy;

- high corrosion resistance and electrical insulation due to the PP surface coating.

Bakelite insulators

These parts are made of Bakelite, which has insulating properties and heat resistance. It prevents leakage of electricity with electrical lines.

The fourth feature: Operational safety

Chain drive clutch with protective cover

Pockets for power and signal cables

Support pulley for belts and cables

Crane Wheels

Flooring

PP injection technology on the surface of parts for the purpose of sealing and corrosion protection, developed with the support of the largest Taiwanese company Formosa Plastic (Taiwan).

The fifth feature: High quality assurance of manufacturer line configuration

| Programmable Logic Controller | made in Japan (Mitsubishi) |

| Power Inverter | made in Japan (Mitsubishi) |

| Bearings | made in Japan |

| Baths and drums material | Polypropylene made in Germany (Röchling Engineering Plastics KG) |

| Cranes | Taiwan production |

| Rectificators | Taiwan production |

| FILTERS | Taiwan production |

| Heaters | Taiwan production |

| Mixing baths | Taiwan production |

| Unloading stand | Taiwan production |

| Sliding rail trolley | Taiwan production |

| Transformers | Taiwan production |

| Engines | Taiwan production |

| Cooling towers | Taiwan production |

| Compressor | Taiwan production |

By purchasing our equipment, you become the owner of the galvanic line of the highest quality made by skilled engineers. We can say with confidence that by choosing the Taiwan manufacturing equipment, you gain an advantage over rivals in terms of economic growth, technological versatility and image producers who care about the environment. On request, galvanic line can be equipped with optional equipment for drains and emmissions treatment.

The manufacturer has more than 20 years of experience in plating lines. The main consumers of our products are manufacturers of metal products for the automotive industry. We established partnership with such car companies as Volkswagen, Honda, Toyota. The geography of our supplies include Japan, Korea, Hong Kong, China, Singapore, Thailand, Indonesia, Philippines, Malaysia, Vietnam, Sri Lanka, Turkey, Iran, Pakistan, India, Egypt; Jordan, Dubai, Saudi Arabia, UAE, Romania, Germany, Holland, Ghana, South Africa, Mexico, Brazil, Argentina, USA, Russia and CIS countries. Finished processed products have passed the necessary certification.

For drawing up the terms of reference and determine the cost of equipment for galvanizing, phosphatizing and plating you should provide the information that you need and the conditions under which the product will be used. Get acquainted with the catalog of our products from the theoretical and technological component of the galvanic process. We will offer the best solution to your problem.

Please, fill in the form for commercial offer: