SURFACE TREATMENT EQUIPMENT

APPLICATION OF ELECTROPLATING PROCESS

Plating is used almost universally, example is: coins, components for cars, motorbikes and bicycles, computer components, parts of course, glass, buttons for clothing, stationery, fishing equipment, fasteners (bolts, nuts, drillers, nails etc.) and various products for planting. Electroplating radically changes the mechanical properties of the metal parts and give it a gorgeous decorative qualities. If you need to extend the life of the part or assembly - consider plating. Electroplating is one of the most effective and proven methods in metalworking.

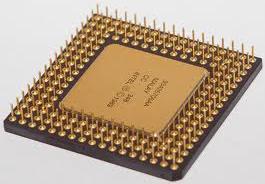

In addition, the electroplating is widely used in electronics and manufacturing of electronic components, in this case the plating is used as protection from the damaging effects of the environment.

GALVANIZING

Galvanizing - the main way to protect the base metal from corrosion of metal products. Usually this method is used to protect various grades of carbon and alloy steels. Galvanizing in hardware production is used for corrosion protection of articles made of wire and various fasteners.

Zinc coating significantly extend the use of the product and reduces costs for its maintenance and replacement. The principle of protection products based on the zinc coating is determined by the difference in the electrochemical potentials of Zn and Fe. The zinc coating in a wet environment acts as the anode, taking care of all harmful processes of oxidation reactions and thus protecting the base metal products. Inexpensive galvanizing process and a high degree of protection of the base anode metal made it the most popular technology for corrosion protection in the manufacture of metal products.

Technology of electrolytic galvanizing is a chemical process - electrolysis. In the bath with electrolytes there are the two metals, steel products and pure zinc. Electric current is supplied to them. Steel articles are loaded into the quick-btn-cont, and current is supplied to them through special electrodes. Zinc may be used in the form of plates or balls loaded into the special section of mesh, or other form. Zinc is also subjected to current. During electrolysis, the zinc (anode) is dissolved, and the ions are deposited on the surface of steel products, forming a plating of 4 to 20 microns thickness.

Anodic dissolution of the zinc electrode occurs as a result of electric current passing through the electrolyte to the cathode of from 1 to 5 A / dm2 density. With this technology zinc coating is obtained a uniform, glossy finish. Currently, to protect products against corrosion in the hardware production is used three ways of galvanizing: cyanide, alkaline and acid.

Cyanide is highly toxic method due to the presence in the electrolyte of sodium cyanide and sodium hydroxide, and zinc oxide. By varying the percentage of components can be given different properties of the electrolyte. Positive aspects of cyanide electrolytes is plating lines high performance, good hiding power, parts of complex shape can be processed, durability and ease of electrolyte adjustments. The disadvantages of this galvanizing technology should include a high degree of environmental hazard and appeared from carbon steel hydrogen embrittlement of products. Hydrogen embrittlement is a most significant drawback, especially for high-strength fasteners, greatly reducing their static and fatigue strength. An alternative to cyanide electrolyte alkaline electrolytes can be used which contain 1-2 grams of zinc oxide and 10-20 g of sodium hydroxide in 1 liter of solution. Such electrolytes are less hazardous to the environment than the cyanide ones, but they are also not without drawbacks.

Alkaline electrolytes are recommended only for steel; galvanizing process stops by heating the electrolyte more than + 30 ° C. Just as in the cyanide method of galvanizing, there is a significant hydrogen absorption of blanks that prevents the use of this method of galvanizing for corrosion protection of high-strength fasteners. When using the modern technology of alkaline galvanizing coatings are highly decorative. The use of different passivators allows to give coating any color - from white with a bluish tinge to dark olive-green and even black.

The most popular galvanizing technology is the technology of the galvanizing in weakly acidic electrolytes. This technology improves appearance of the zinc coating. This method further reduces the tendency of zinked products of carbon and alloy steels to hydrogen embrittlement and allows galvanize parts of complex configurations made of both steel and cast iron. In today's hardware production, this method of applying a protective coating is the most common among manufacturers of fasteners.Galvanizing in weakly acidic electrolytes allows you to get the most decorative effect. Products with a protective coating of zinc, obtained by weak acid galvanizing technology, have high gloss, various colors and high corrosion protection.

All plating technologies require high quality blanks surface preparation. Before the process of galvanizing it is necessary to clean the surface of the scale, technological lubricant residues, corrosion products (rust). After applying a zinc coating for greater stability and resistance of the coating it is subjected to lightening (etching - pickling in a weak solution of nitric acid) and passivation. Passivation gives zinc coating not only additional corrosion resistance but also improves decorative, adding extra shine or coloring coating in different colors.

TYPE OF PROCESSED PRODUCTS

|  |  |  |

| bolts | nuts | nails | screws |

|  |  |  |

| springs | Screws | washer | fasteners |

|  |  |  |

| metal pipes | bearings | wire | self-tappers |

|  |  |  |

| logos, icons | car disks | hooks | motorcycle details |

|  |  |  |

| metal profile | coins | PC hardware | sanitary engineering |

|  |  |  |

| electronic boards | steel buttons | golf balls | bicycle frames |